Phenolics and epoxy resins are two types of commonly used thermosetting resins. Both these resins are cured prior to carbonization; since they are thermosets, they will not flow the fibrous preforms during first carbonization.

Resin matrix composites are fabricated from preimpregnated carbon fiber layers of woven fiber cloth. This type of material is preferred when fabricating complex shapes. The materials technology involves the impregnation of one layer of carbon fibers with a resin. This prepreg is partially cured to a fixed degree of tackiness and can be used immediately or refrigerated for 6 to 12 months. Prepregs are cut and combined according to the need and hot-pressed or cured in an autoclave to produce a rigid solid. They are then pyrolyzed and subsequently densified by

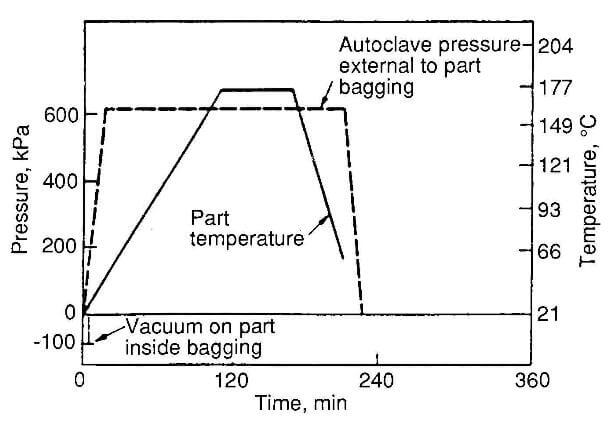

typical hot-pressing cycle for processing phonolic matrix composites.

repeated infiltration/carbonization cycles. Although some new resin precursors have been developed that have higher carbon content (>80%), the carbon char yield in commercially available resins can be as low as 50% or as high as 70%, depending on the resin and processing conditions.

In a typical process, multiple layers of prepreg fabric are laid up on a mold before being pressed at given temperature (150C to 300C) under a given pressure of 0.69Mpa to 3.45Mpa for up to 10 hours.

The exact processing conditions are dependent on the time/viscosity properties of the resin used in the prepreg. A typical hot-pressing cycle is shown in figure 4. During hot pressing, the resin softening allows the air pockets to be squeezed from between the laminates. The pressure is usually applied continuously during cool down.

Composites described in the previous paragraph are carbonized at atmospheric pressure under inert gas flow. Carbonization to -800C is usually carried out slowly in order to prevent the rapid evolution of

carbon fiber composite material manufacturer in China(1)

volatiles such as H2O and CH4 and to prevent consequent delamination between the woven layers. The carbonization cycle may take many hours or sometimes days to complete.

During carbonization the resin matrix is converted to carbon, the porosity increases typically from 3 to 25 percent, and the density decreases from 1.5g/cm3 to 1.3g/cm3. The carbonization composite is repeatedly heat-treated to higher temperature (graphitization) and reinfiltrated to complete the densification process.

Densification cycles can carried out using either resin, CVI, or pitch feedstocks. If a resin impregnant is chosen, one with low room temperature viscosity is used. Furfural alcohol and phenolic dissolved in isopropanol are examples of frequently used infiltrants. In order to fill the smallest pores, impregnation can be carried out using a low pressure (3445Pa).

Since the density of resin char is relatively low, resin densification required more cycles than those necessary using other precursors. Up to five cycles of resin impregnation are required to obtain a composite with a density of about 1.5g/cm3 to 1.8g/cm3.

related news /articles:

Liquid phase infiltration of CC composites– Pitch matrices

Methods of processing carbon-carbon materials (1)- gas phase

Carbon fiber carbon matrix composites manufacturing processes

Gas phase infiltration of carbon carbon composites-CFCCARBON LTD