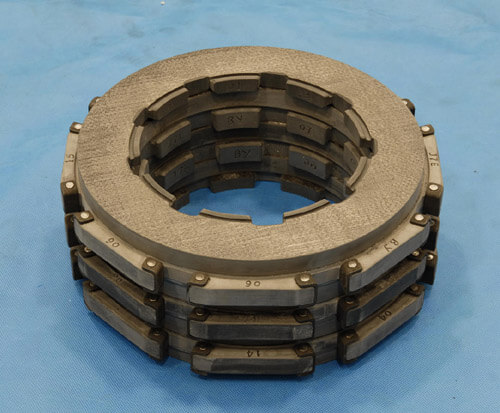

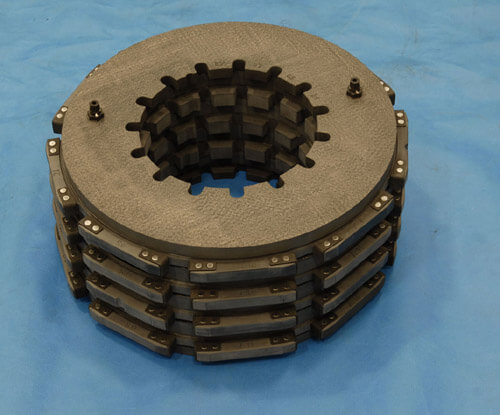

carbon carbon composite airplane brakes, brake pairs

We can produce all kinds of carbon carbon composite Airplane brakes, brake pairs.

See bellow standard propersties:

Product name: carbon carbon composite/ CFC/ CC

Type: 2.5D

Main application: Airplane Brakes

Detailed description

We can produce all kinds of carbon carbon composite Airplane brakes and brake pairs. Our C/C composite airplane brake disks and plates have been used successfully for many years in the civil aviation aircrafts, quality is stable. We have CAAC standard in China. We have supplied to Airbus, Boeing airlines in China.

We are mainly engaged in research, development, production and sales of carbon-carbon and carbon ceramic composite materials.

See bellow standard propersties of CC composite brakes:

Product name: carbon carbon composite/ CFC/ CC

Type: 2.5D carbon composite

Main application: Airplane Brakes

| ITEM | UNIT | 2.5D |

| Bulk density | g/cm3 | ≥1.78 |

| Carbon content | % | ≥99.99% |

| bending strength | Mpa | 140 |

| Compressive strength | Mpa | ≥180 |

| interlaminar shear strength | MPa | >15 |

| Thermal conductivity | W/mk | 20~80 |

| coefficient of dynamic friction | 0.24-0.42 (adjustable) | |

| coefficient of static friction | 20.6MPa 3000psi | ≥0.16 |

| Inertial platform linear wear | Um/time/face | ≤1.5 |

| Processing temperature | ℃ | >2000 |

| Ash content | ppm | ≤100 |

| Metal ash content | ppm | ≤50 |

C/C Airplane brakes /disc has advantages of long lasting lifetime, low competitive costs, more clean…

What is the 2.5D carbon carbon composite? Its based on the 2D carbon composite, and has some fibers between the layers of carbon cloths. Its 3directions, but the z direction has less fibers. We call it 2.5D. Our carbon composite aipane brakes are made of this type of material. its sepcially designed for airplane brakes. Carbon / carbon composite material is a porous brittle material, afraid of wet, afraid of oil, fear of oxidation, fear of bruising, fear of bruising, fatigue, compared to Steel, Therefore, carbon composite brakes have their own characteristics of the use of maintenance.

The main features of carbon-carbon brake discs

1). Carbon-carbon brake disc density is 1 / 4-1 / 5 of steel . Because the brake weight is lighter than steel about 40%. the Aircraft performance improved significantly.

2). The Specific heat, thermal expansion coefficient is small, high strength stable at high temperature, so deformation and melting will not occur.

3). Friction and wear performance is good. the use of wear and tear is about 25% -50% of steel. Ordinary military machine life of 1000 times ups and downs, the Civil aircraft up to 3000 times ups and downs. Carbon-carbon brake discs wear to the limit size, you can also renovation.

We can do X-RAY tests and other tests.

Code: B757-200, for Boeing 757; Airbus 320; C919;

We can produce with all shapes of CC Airplane brakes /brake pairs, as per customers’ special request.

Quality guaranteed and competitive prices.

Video of carbon fiber composite airplane brake discs:

Related products /news:

Carbon carbon composite aircraft brakes/brake disc/ brake disk

Data sheet of C/C composite for airplane brakes/disc

Data sheet of 2.5D C/C Composite material for airplane brake discs