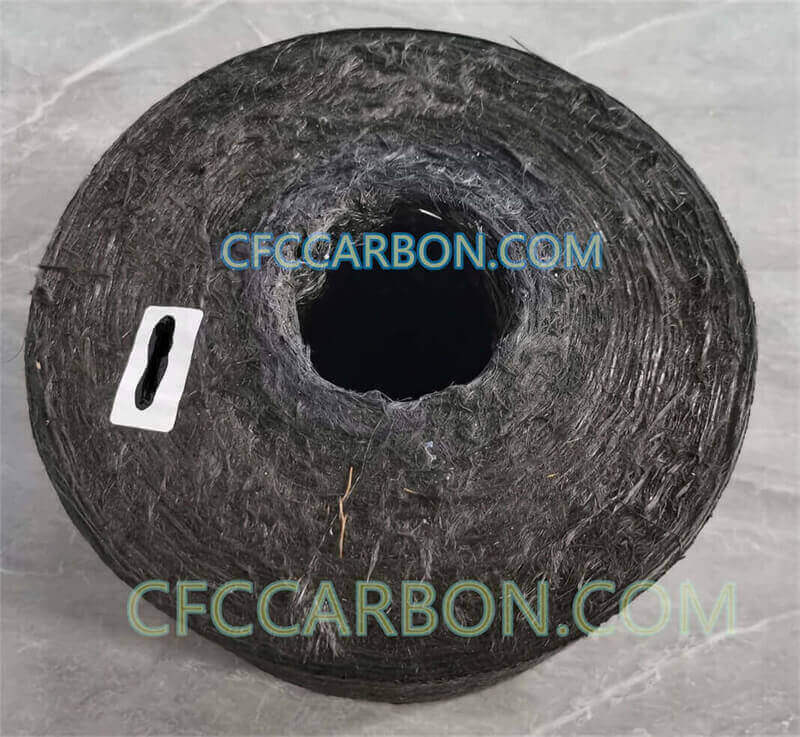

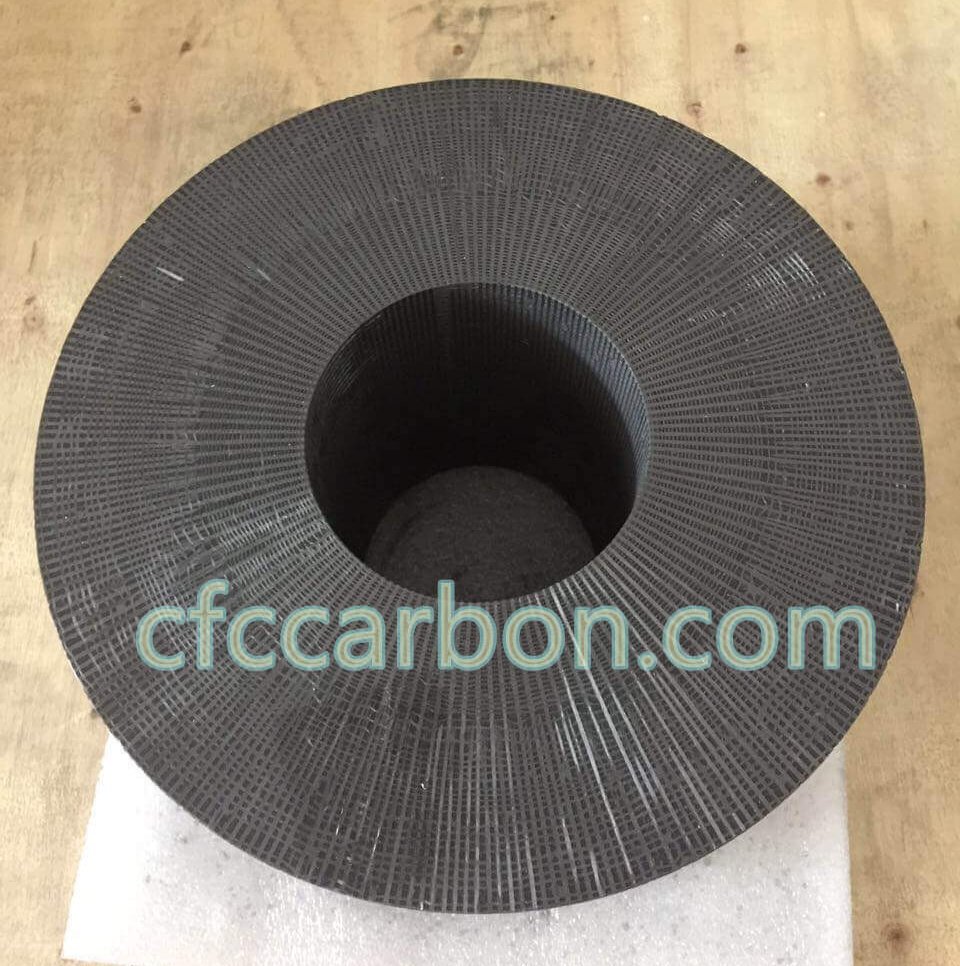

Carbon carbon composite mould, CFC mould

Our company can supply carbon composite mould with stable and reliable quality. We can produce all kinds of cfc mould. With material: 2.5D, 1.6-1.9g/cm3; 3D, 1.5-1.9g/cm3; 4D 1.5-1.9g/cm3. as per customers’ requests. CFC mould has advantages of long lifetime and low competitive costs, compared to graphite mould.

Detailed description

We can produce high performance carbon composite moulds /molds with stable and reliable quality. We can produce all kinds of C/C composite moulds with material: 2.5D, 1.6-1.9g/cm3; 3D, 1.5-1.9g/cm3; 4D, 1.5-1.9g/cm3, as per customers’ requests. CFC moulds has advantages of long lifetime and low competitive costs, compared to graphite moulds.

Standard properties for carbon carbon composite mould:

| Specification | analysis |

| Bulk density | >/=1.7 g/cm3 |

| Flexural strength | >/= 100Mpa |

| Ash content | </= 50ppm |

| Carbon content | >/= 99.99% |

| C.T.E | </=3 ×10-6/K |

| Specific resistance | 30-50 uΩ.cm |

| Temperature (no oxygen environment) | 2300 °C |

Note: We can produce with all shapes of mould, as per customers’ drawings or samples.

Applications of C/C composite moulds: CC composites mould has been widely used in aerospace, automotive, medical and other fields due to their unique properties.

Advantages: High strength, high specific modulus, high thermal conductivity

Features/characteristics of C/C composite mould:

Although C/C composites have many excellent high temperature properties, it will be oxidized in an aerobic environment at temperatures above 400 ° C, resulting in a sharp drop in material properties. Therefore, the application of C/C composites in high temperature aerobic environments must have oxidative protective measures. The oxidation protection of C/C composites mainly protects the C/C composites through the following two ways, that is, the substrate can be modified at the lower temperature and the passivation of the surface active point. With the increase of temperature, It is necessary to use the coating method to isolate the carbon / carbon composite material and oxygen in direct contact to achieve the purpose of oxidation protection. At present, the most widely used coating method, with the continuous progress of technology, carbon / carbon composite materials, more and more dependence on ultra-high temperature performance, and in ultra-high temperature conditions, the only viable oxidation protection program can only be coated Protection.

We can produce C/C composite hot pressed mould too. Properties / data sheet available in other pages with more details.

You can see bellow a video for high performance 4D carbon composite mould, which reaches density of 1.90g/cm3:

Our Products were sold throughout the country and exported to Europe, America, Southeast Asia and other countries and regions which enjoy a high reputation all over the world. We hope to establish a good business relationship with you; we will serve you with the best quality, best delivery time and best solutions