Carbon ceramic composite material and products

Carbon ceramic composite (C/-SiC) is a carbon fiber reinforced SiC ceramic composite. The main matrix component of SiC determines the hardness of the composite, the effect of carbon fiber is to improve the mechanical strength and fracture toughness of the material, and its strength is 5 times higher than steel.

Detailed description

Advanced Ceramic Matrix Composites (CMC) by CFCcarbon: Innovation Engineered for Extreme Performance

As a professional ceramic matrix composite (CMC) manufacturer in China, CFCcarbon delivers cutting-edge carbon-ceramic materials engineered to outperform metals and traditional ceramics in the world’s most demanding environments. Our composites combine carbon fiber reinforcement with advanced ceramic matrices (SiC, carbon) to create ultra-lightweight, ultra-durable solutions for aerospace, automotive braking, and energy applications.

The carbon ceramic composite material has the advantages of low density, high temperature oxidation resistance and corrosion resistance, and is a new type of high temperature structure material and functional material which can meet the use of 1650 degrees centigrade. Carbon ceramic composite materials will become a new generation of aircraft and automotive brake materials.

Carbon fiber reinforced carbon-silicon carbide (Cf/C-SiC), also named carbon/silicon carbide (C/SiC), or ceramic composite. It has been progressively used as a replacement of cast iron for producing brake discs used in high performance cars since such application was successfully demonstrated more than a decade ago. By now, almost all commercial C/SiC brake discs are paired with pads that are made of C/C composite material (also called organic pad), a type of composite that all abrasives, lubricants are included to improve the wear resistance, thermal diffusivity and mechanical robustness. Organic pads themselves are widely used to pair with cast iron brake disc for a brake in a road vehicle. As known already, friction performance of a brake is highly sensible to the composite of such type of friction material. However, there is not yet sufficient tribological knowledge published about a friction pair that consists of C/SiC and low metallic friction material, whilst one may expect that extensive testing must have been done in industry to achieve/optimise the required friction performance of a carbon ceramic brakes.

Why Choose CFCcarbon as Your CMC Manufacturer?

-

Precision Engineering

We utilize proprietary processes like Chemical Vapor Infiltration (CVI) and Polymer Infiltration Pyrolysis (PIP) to manufacture ceramic matrix composites with superior:-

Temperature resistance (up to 1,800°C in inert atmospheres)

-

Mechanical strength (3x higher than monolithic ceramics)

-

Thermal shock resistance

-

Abrasion/corrosion immunity

-

-

Core Product: Carbon-Ceramic Composites (C/C-SiC)

Our flagship material, carbon fiber reinforced silicon carbide (C/C-SiC), offers:-

Density: 1.8–2.0 g/cm³

-

Flexural Strength: 80–150 MPa

-

Thermal Conductivity: 15–40 W/(m·K)

-

CTE: 3.0–4.0 × 10⁻⁶/K

Custom formulations available for specific thermal, mechanical, or tribological needs.

-

-

End-to-End Manufacturing Capabilities

From raw material synthesis to final machining, our vertically integrated facility ensures:-

ISO 9001-certified production

-

Prototype-to-mass-production scalability

-

Strict non-destructive testing (NDT) standards

-

Applications: Where Our Ceramic Matrix Materials Excel

| Industry | Use Cases | Key Benefits |

|---|---|---|

| Aerospace | Rocket nozzles, thermal shields | Lightweight, zero ablation, 2,200°C capability |

| Automotive | Brake disks, clutch systems | 50% weight reduction, fade-free braking |

| Industrial | Semiconductor fixtures, furnace parts | Zero contamination, thermal stability |

| Energy | Heat exchanger tubes, reactor liners | Corrosion resistance, longevity |

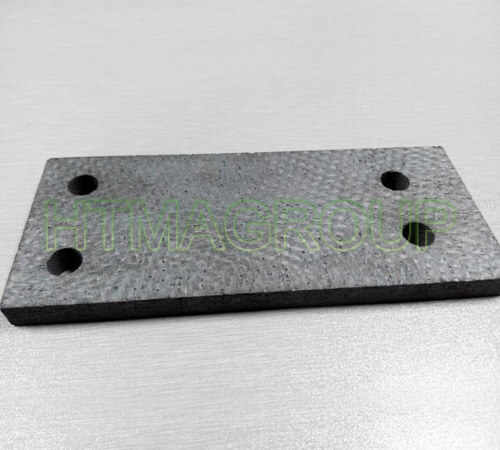

You can see bellow some photos of our C/SiC composite brakes for racing cars. We provide the best quality with low prices, our products are widely used all over the world.

carbon ceramic composite (C-SiC) brakes for racing car-2

carbon ceramic composite (C-SiC) brakes for racing car-3

We are manufacturer of carbon carbon composite and carbon ceramic composite in china, with stable and reliable quality. Our C/C composite products: 2D,2.5D,3D,4D carbon composite, with density from 1.40-1.95g/cm3, with CVD, CVI processing, or pitch based carbon composite. also, we produce carbon ceramic composite material and products.

Our Products were sold throughout the country and exported to Europe, America, Southeast Asia and other countries and regions which enjoy a high reputation all over the world. We hope to establish a good business relationship with you; we will serve you with the best quality, best delivery time and best solutions.

Partner with a Trusted CMC Supplier

CFCcarbon is China’s premier ceramic matrix material manufacturer for clients requiring:

✅ Custom material formulations

✅ High-volume production (1,000+ units/month)

✅ CNC machining of complex CMC parts

✅ R&D collaboration for novel applications

Contact our engineers to discuss how our carbon-ceramic composites solve your high-temperature, high-wear, and lightweight challenges:

📧 Email: [potter@cfccarbon.com | 📞 Phone: [86-18910941489]