Discontinuous Reinforcement in Carbon-Carbon Composites: Innovations in High-Temperature Solutions

By CFC Carbon Technical Team | Updated: May 15, 2025

1. What Are Carbon-Carbon Composites?

Carbon-carbon (C/C) composites are advanced materials composed of carbon fibers embedded in a carbon-rich matrix. These composites combine the exceptional mechanical strength of carbon fibers with the thermal stability of a graphite-based matrix, making them ideal for extreme environments. According to CFC Carbon, a leading manufacturer, C/C composites exhibit unparalleled properties such as high-temperature resistance (up to 3000°C), low thermal expansion, and lightweight durability.

2. Discontinuous Reinforcement: A Game-Changer in Manufacturing

Production Methods

2.5D needle punch CFC carbon fiber composite mould mold preform-preforming-Prefab T700 12K

Discontinuous reinforcement involves integrating short carbon fibers (typically <1 mm in length) into the matrix through techniques like isotropic casting or pulp molding. Unlike continuous fibers, these fragmented fibers are randomly oriented, enhancing isotropic behavior and reducing production costs. For instance, CFC Carbon utilizes pitch-based matrices combined with chopped fibers to achieve a balance between machinability and structural integrity.

Product Categories

Discontinuous C/C composites are classified based on fiber orientation and porosity levels:

-

Random In-Plane Fiber Composites: Optimized for uniform thermal conductivity in furnace insulation.

-

Concentric Fiber Arrangements: Used in cylindrical components like rocket nozzles for radial strength.

Applications

-

High-Temperature Insulation: Replacing ceramic materials in vacuum furnaces due to cost efficiency and superior shape retention7.

-

Aerospace Components: Rocket nozzle liners and thermal protection systems (TPS) for re-entry vehicles.

carbon fiber composite material manufacturer in China(1)

-

Industrial Heating Systems: Customizable insulation boards and heat shields for glass manufacturing.

Performance Advantages

-

Thermal Conductivity Control: Fiber orientation perpendicular to material thickness minimizes heat transfer, ideal for insulation7.

-

Machinability: Short fibers enhance rigidity, allowing precise machining of complex geometries.

-

Cost-Effectiveness: 30–50% lower production costs compared to continuous fiber composites.

3. Overcoming Challenges: From Lab to Market

While early discontinuous C/C composites faced limitations in load-bearing applications, advancements in fiber-matrix bonding have expanded their use. For example, CFC Carbon’s CX-Series integrates nano-modified carbon matrices to improve fracture toughness by 40%6. Additionally, hybrid designs combining discontinuous and continuous fibers are now used in aircraft brake systems, reducing weight while maintaining performance.

4. Case Study: Porous C/C Insulation in Industrial Furnaces

A breakthrough application lies in porous C/C insulation materials with 85–90% porosity. These materials outperform traditional ceramic insulation by offering:

-

Higher Temperature Tolerance: Stable up to 3000°C in inert atmospheres.

-

Reduced Thermal Mass: Faster furnace cycling and energy savings.

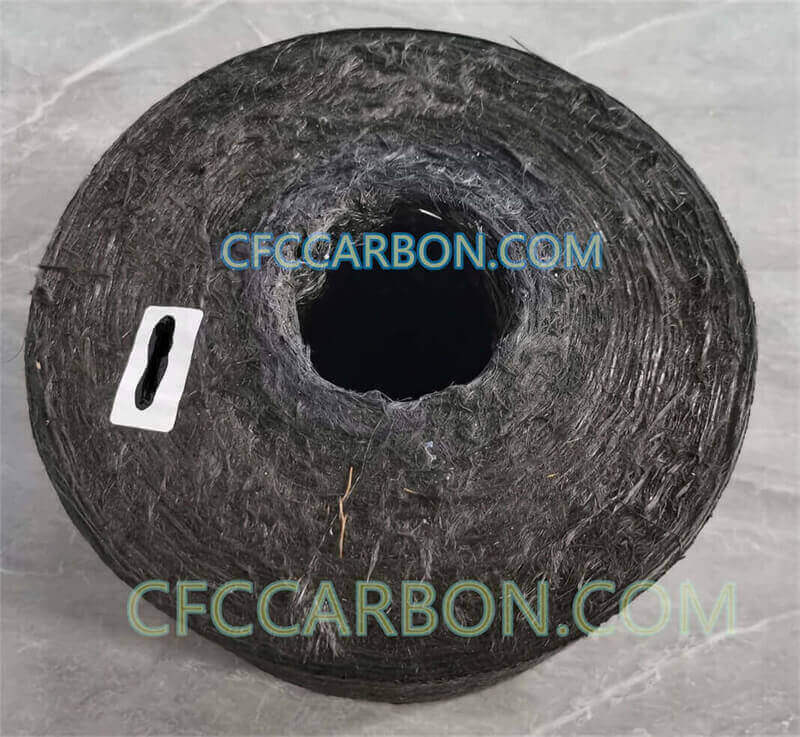

Figure 1 illustrates a cylindrical C/C insulation component with concentric fiber alignment, widely adopted in semiconductor manufacturing furnaces.

5. Future Trends and Sustainability

The global demand for discontinuous C/C composites is projected to grow at 7.2% CAGR by 2030, driven by renewable energy and aerospace sectors. Innovations like recyclable carbon fibers and AI-driven fiber placement (e.g., CFC Carbon’s Automated Fiber Placement systems) are set to revolutionize production efficiency.

Explore CFC Carbon’s Solutions

CFC Carbon offers tailored discontinuous C/C composites for diverse industries. Visit www.cfccarbon.com to discover our CX-Series products, including:

-

2D/3D carbon preforms

-

CVD/CVI-processed components

-

Custom insulation designs

related news /articls:

Continuous and discontinuous carbon fiber composites

Data Sheet of C/C Composite for Airplane Brakes/Disc

4D C/C composite material manufacturer in China

Carbon fiber Composites: Innovations and Applications in Aerospace and Beyond