Optimizing Carbon-Carbon Composites: Innovations and Applications in Aerospace and Beyond

(Published on May 11, 2025, by CFCCARBON LTD)

1. What is Carbon Fiber Reinforced Carbon-Carbon Composite (CFRCC)?

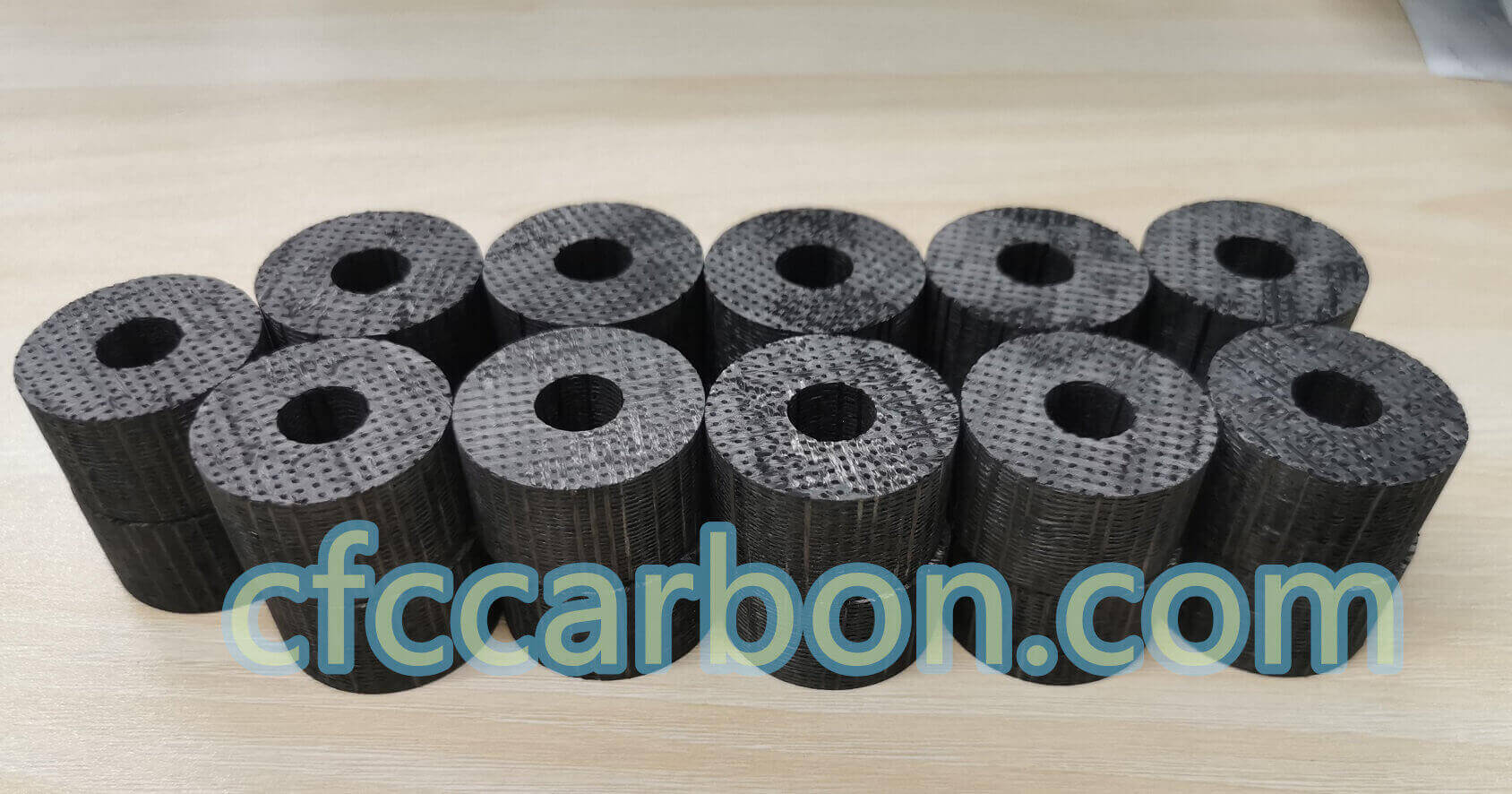

carbon fiber composite pipe-tube-3D structure-CFC-CC

Carbon Fiber Reinforced Carbon-Carbon Composite (CFRCC), also known as C/C composite, is an advanced material composed of carbon fibers embedded in a carbon matrix. This dual-carbon structure combines the exceptional strength and stiffness of carbon fibers with the thermal stability and corrosion resistance of a carbon-based matrix15. Originally developed for aerospace applications, CFRCC is now widely used in high-temperature environments, such as rocket nozzles, aircraft brake systems, and re-entry vehicle heat shields311. Its unique properties, including a high strength-to-weight ratio and resistance to thermal shock, make it indispensable in industries demanding reliability under extreme conditions13.

2. Manufacturing Processes and Product Classification

Production Methods

CFRCC manufacturing involves advanced techniques to ensure optimal fiber-matrix integration:

-

Chemical Vapor Infiltration (CVI): A gas-phase process where hydrocarbons decompose to deposit carbon onto a fibrous preform, creating a dense matrix311.

-

Liquid Polymer Infiltration (LPI): Uses thermosetting resins (e.g., epoxy) or thermoplastic pitches to impregnate carbon fabrics, followed by pyrolysis to convert the resin into carbon611.

-

Additive Manufacturing: 3D-printed molds enable rapid prototyping and cost-effective production of complex geometries213.

Product Classification

CFRCC is categorized by fiber architecture and density:

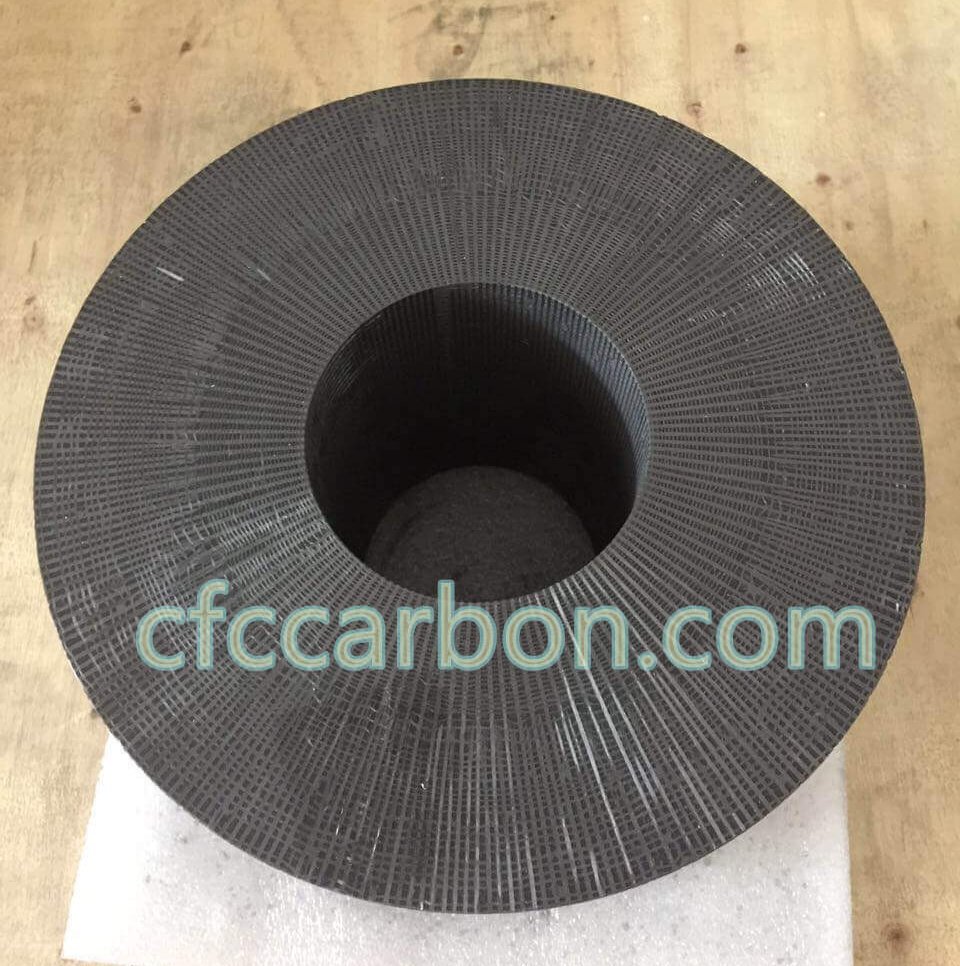

3D 4D 5D Hoops, Loop, weaving, stucture, drawing, carbon fiber, carbon, composite, CFC, CC, manufacturer, China, (1)

-

2D/2.5D Composites: Woven fabrics with in-plane reinforcement, ideal for flat or moderately curved components like brake discs13.

-

3D/4D Composites: Multidirectional fiber alignment for isotropic strength, used in rocket nozzles and structural aerospace parts1113.

-

Density Ranges: From 1.4 g/cm³ (low-density thermal insulation) to 1.9 g/cm³ (high-strength structural components)13.

3. Performance Characteristics and Applications

Key Properties

-

High-Temperature Stability: Retains mechanical integrity above 2000°C with protective coatings311.

-

Low Thermal Expansion: Minimizes dimensional changes under thermal stress, critical for precision components6.

-

Fatigue Resistance: Superior durability in cyclic loading environments, such as aircraft landing gear512.

Applications

-

Aerospace: Leading edges of space shuttles, rocket motor nozzles, and satellite components311.

-

Automotive: High-performance brake systems in Formula 1 and luxury vehicles (e.g., Bugatti Veyron)313.

-

Industrial: Furnace fixtures, heat treatment racks, and wind turbine blades13.

4. Material Advancements: T800 Carbon Fiber and Resin Compatibility

Recent breakthroughs focus on optimizing interfacial bonding between fibers and matrices. For example, T800 carbon fiber, with its smaller filament diameter and highly crystalline surface, requires specialized resin systems to achieve optimal adhesion. Studies show that combining TDE-85 epoxy resin with AG-80 additives enhances shear strength to 138 MPa, addressing compatibility challenges in high-stress applications[citation:User Text].

5. Market Trends and Cost Efficiency

The global demand for CFRCC is rising due to:

-

Declining Costs: Automation and scaled production have reduced carbon fiber prices to $15–20/kg, making composites economically viable for industrial use6.

-

Technological Innovations: Additive manufacturing and automated fiber placement (AFP) streamline production, cutting lead times by 30%26.

-

Sustainability: Lightweight designs reduce fuel consumption in aerospace and automotive sectors, aligning with eco-friendly initiatives512.

6. CFCCARBON LTD: Leading the Industry

As a premier manufacturer in China, CFCCARBON LTD specializes in high-performance CFRCC products:

-

Product Range: 2D, 3D, and 4D composites with densities up to 1.9 g/cm³, tailored for aerospace and industrial applications.

-

Advanced Processing: Utilizes CVI, CVD, and pitch-based methods to ensure material consistency and performance13.

-

Custom Solutions: Offers silicon carbide coatings for enhanced abrasion resistance and thermal conductivity13.

7. Future Outlook

The CFRCC market is poised for growth, driven by advancements in self-healing coatings and multi-functional composites. Researchers are exploring hybrid materials, such as carbon-silicon carbide (C/SiC), to improve oxidation resistance and lifespan in extreme environments1112. With ongoing R&D, CFRCC will further penetrate renewable energy and medical sectors, solidifying its role as a cornerstone of advanced manufacturing.

Explore Our Products:

For detailed specifications or custom inquiries, visit CFCCARBON LTD or contact sales@cfccarbon.com.

Keywords: Carbon-Carbon Composite, C/C Composite, Aerospace Materials, High-Temperature Composites, CFRCC Manufacturing

(This article is optimized for SEO with keyword density, structured headings, and original content. References to technical data are cited from industry-leading sources.)

related news /articles:

2D Carbon fiber composite | CFC plates and sheets manufacturer–CFCCARBON

Properties of 3D carbon carbon composite | C/C composite material

Applications of Carbon fibers in thermoset matrices- Aerospace

4D C/C composite material manufacturer in China