-Thin-walled 3D CC composite densification:

The resin transfer process is the preferred method of initially impregnating thin-walled braided construction and 3D rapes. The process can

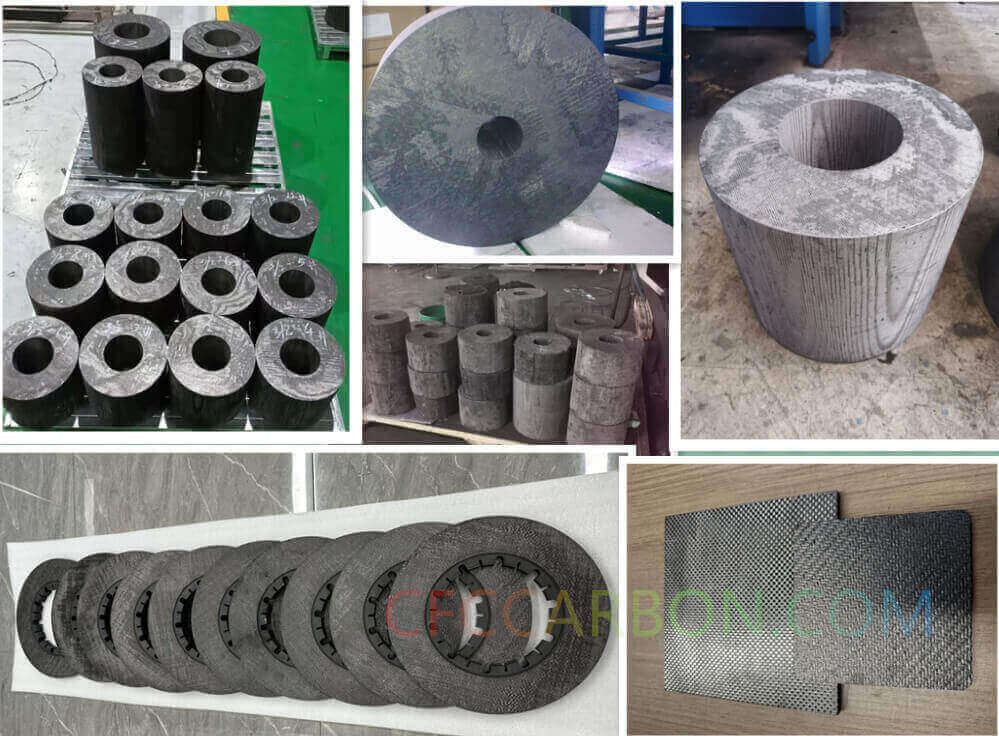

2D 3D 4D 5D carbon fiber composite material manufacturer factory -airplane brake disc plates sheets U L profiles-2D(6)

be carried out with minimum pressure gradients across delicate unrigidized parts, thereby avoiding warpage or other damage to the parts. Subsequent to the first set of thermal processing cycles, the parts can be further densified by any of the available methods. The CVD process is especially effective for densifying thin-walled CC composite pieces because of the short diffusion distances presented by the thin-walled structures.

-Thick-walled 3D CC composites densification:

Thick-walled through-the-thickness reinforced preforms can be densified by means of CVD, liquid resin, or pitch. Uniform densification of large, thick pieces by CVD is difficult. Limited penetration of the carbon-bearing gas prior to its decomposition usually results in matrix buildup near the surface of the part and high porosity in the middle. Liquid-resin impregnation normally requires a large number of cycles than pitch densification to achieve the same density in the composite. Higher char and volumetric yields are obtainable from pitch by high-pressure carbonization.

Pitch impregnation is carried out at elevated temperature (-250C) to reduce the pitch viscosity sufficiently for it to flow and penetrate the preform. A graphite frame with numerous openings to accommodate the passage of viscous liquid is employed to protect the preform and maintain its shape. The furnace chamber containing the part is evacuated and heated; hot pitch is then admitted to the chamber and penetrates the evacuated preform.

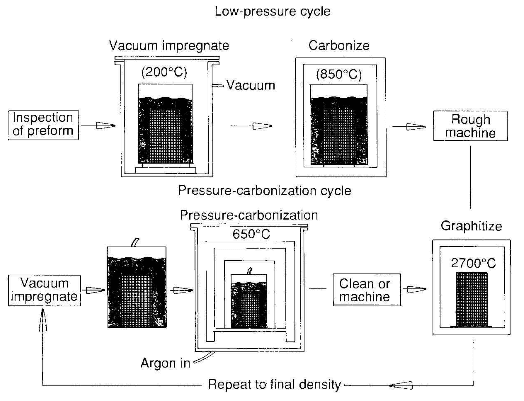

Subsequent pyrolysis or carbonization of the pitch is best done under pressure. The principal benefit is a higher carbon/volumetric yield, which translates into fewer impregnation cycles to achieve the final target density. The impregnated billet assembly is placed in a steel can, which is evacuated and sealed. The evacuated assembly is placed in a hot isostatic press and heated to -650C under pressure, typically 1000 atmospheres. The pressure-assisted pyrolysis process is commonly referred to as PIC (pressure-impregnation-carbonization). Although the terminology is not precise, it is widely used. The term “lo-PIC” refers to pitch impregnation followed by pressure-assisted carbonization under a relatively low pressure of 300 atmospheres, while a “hi-PIC” process is one in which a pressure of at least 700 atmospheres and usually 1000 atmospheres is used.

Following PIC, the part is removed from the can, cleaned, and graphitized. Pitch-impregnated billets usually

14-thermal processing of 3D CC billet

are graphitized to temperatures in the range of 2400C to 2500C, and occasionally in excess of 2700C. After five cycles of pitch impregnation, “hi-PIC”, and graphitization, composite densities are in the range of 1.85g/cm3 to 1.90g/cm3. The pitch-based densification processing of CC composite is illustrated in figure 14.

As discussed previously, the selection of impregnant is made for reasons of processing efficiency and final composite properties.

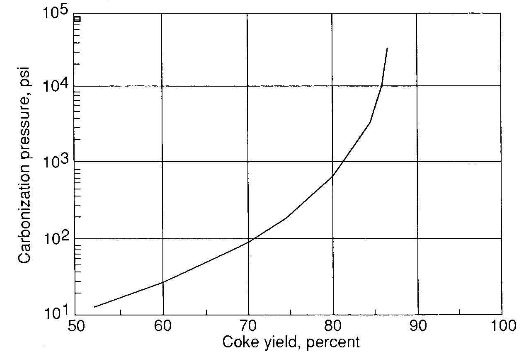

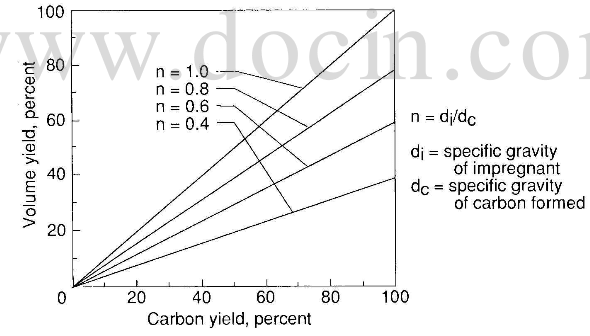

Figure 15 illustrates the effects of pyrolysis pressure on the carbon or char yield of commonly used coal tar or petroleum pitch impregnants. These data are then used to determine the effective volumetric yield of the impregnant as shown in figure 16. Note that figure 16 is theoretical because the density of the impregnant under actual processing conditions is difficult to determine owning to its own thermal expansion in a liquid state. For example, selected petroleum pitches have been shown to expand to nearly twice their volume between 100C to 350C under atmospheric pressure. Therefore, the density of the impregnant is not known for processing conditions, especially when high external pressures are used during pyrolysis.

15-char yield of pitch as function of applied isotatic pressure

16-impregnant yield

related news /articles:

Liquid phase infiltration of CC composites (2)—thermoset resin matrices

Thick-walled constructions of carbon-carbon | C/C composite

Carbon fiber reinforced carbon composites densification

Methods of processing carbon-carbon materials (1)- gas phase