Through-the-thickness reinforcement (typically 3D C/C composite) overcomes some of the limitations of 2D CC composite. Braiding and weaving are the two methodologies employed to fabricate preform structures having through-the-thickness reinforcement.

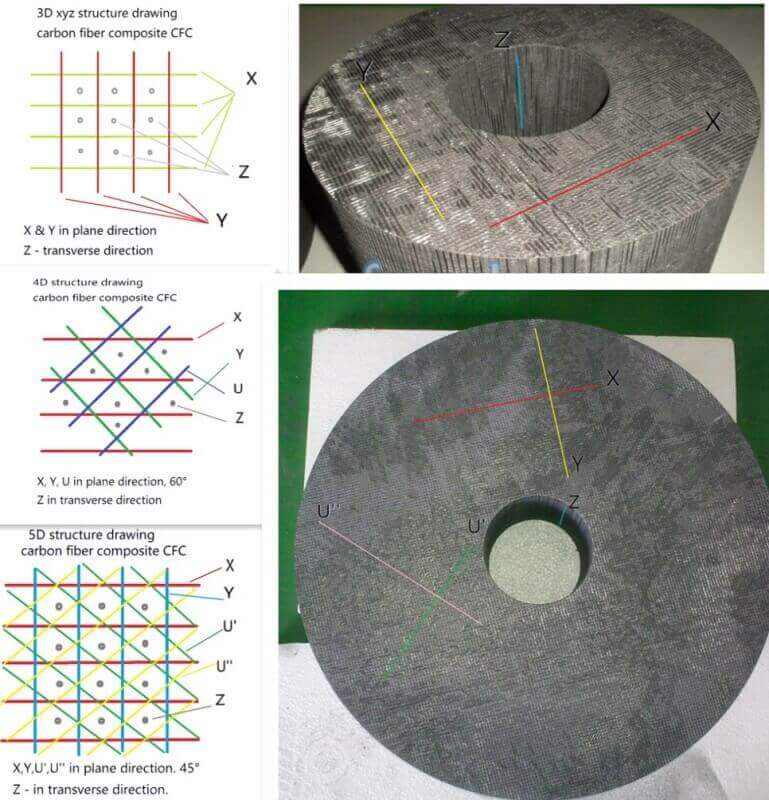

3D 4D 5D carbon fiber composite CFC structural diagram drawing material (1)

Braiding is appropriate for making curved thin-walled structures. Braided components can be fabricated with either through-the-thickness reinforcement or triaxial reinforcement which consists of helical and axial fibers. The braid pattern imparts good longitudinal strength to a thin-walled tube, as would a uniaxial structure resulting from axial fibers. The off-axis fibers in a braided construction tie the structure together and impart bending and torsional stiffness to the structure. These attributes represent significant improvements that make braided tubes preferable to uniaxially reinforced tubes.

Thin-walled parts can be constructed of 3D tape, as illustrated in figure 5. Tape thickness for a single-layer construction depends on the cross section of the yarn used. Typical 3D tapes are multilayered and can be varied in thickness. Three-directional tape constructions are appropriate for flat panels applications in which improved interlaminar shear strength or resistance to thermal shock is required.

related news /articles:

Thermal conductivity data of carbon-carbon composite materials (3)

Introduction of manufacturing and design of carbon-carbon composites

carbon fiber reinforcement and architecture-woven 3D fabrics

Selection of materials for carbon-carbon processing (1)- types of reinforcement