Pyrolytic graphite is a new type of carbon material. It is a pyrolytic carbon with higher crystal orientation that is deposited on a graphite

PG sheet-pyrolytic graphite plate disc crucible pipe tube (4)

matrix of 1800℃~2000℃ by chemical vapor deposition of high-purity hydrocarbon gas under a certain furnace pressure. It has high density. (2.20g/cm), high purity (impurity content (0.0002%) and anisotropy of thermal, electrical, magnetic and mechanical properties. It can still maintain a vacuum of 10mmHg at around 1800°C.

The reaction process in which a substance decomposes when heated. Many inorganic and organic substances will undergo decomposition reactions when heated to a certain degree. The pyrolysis process does not involve catalysts, and other energies, such as reactions caused by ultraviolet radiation.

Our company mass produces various specifications of pyrolytic graphite plates, square and round materials, and can also be processed products; we also produce pyrolytic graphite tubes, pyrolytic graphite crucibles, etc. The price is very advantageous, and the products are exported to many countries and quality Recognized by customers.

Pyrolytic graphite is a new type of carbon material. It is a pyrolytic carbon with higher crystal orientation that is deposited on a graphite matrix of 1800℃~2000℃ by chemical vapor deposition of high-purity hydrocarbon gas under a certain furnace pressure. It has high density. (2.20g/cm), high purity (impurity content (0.0002%) and anisotropy of thermal, electrical, magnetic and mechanical properties. It can still maintain a vacuum of 10mmHg at around 1800°C.

main application

Graphite heater

Diversion bucket

PBN/PG composite heater[1]

Atomic absorption tube

main feature

1. The surface is dense, without pores, and easy to machine.

2. High purity, total impurity content <20ppm, good air tightness.

3. High temperature resistance, the strength increases with the increase in the use temperature, the strength reaches the highest value of

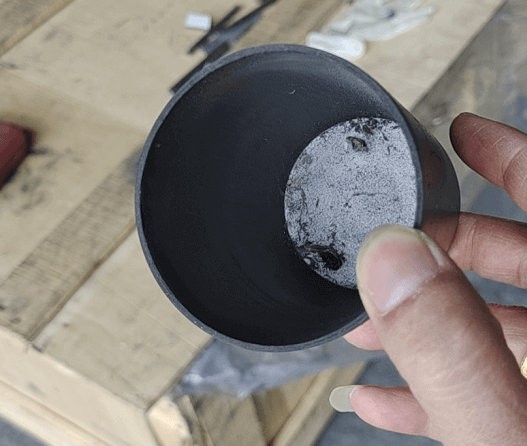

pyrolytic graphite crucible

3600°C at 2750°C and sublimates.

4. Low modulus of elasticity, high thermal conductivity, low thermal expansion coefficient, excellent thermal shock resistance of the product.

5. Good chemical stability, resistance to acid, alkali, salt and organic reagents. It has no effect on molten metal, slag and other corrosive media. The oxidation is not obvious below 400 ℃ in the atmosphere, and the oxidation rate increases significantly at 800 ℃.

6. Do not release any gas at high temperature, and it can maintain a vacuum of 10-7mmhg at around 1800℃.

Application areas of coating products:

1. In the semiconductor industry, pull silicon single crystal diversion tube.

2. Graphite heater coating for semiconductor industry.

3. Wafer annealing process PBN/PG composite heater coating.

4. Pyrolytic graphite coating of atomic absorption tube for analytical instruments.

5. Aluminum crucible for electron beam evaporation.

More video of pyrolytic graphite, please check:

Related news /products:

PG sheet-pyrolytic graphite plate disc crucible pipe tube

Pyrolytic graphite plates

Pyrolytic carbon material, pyrolytic graphite material

Pyrolytic graphite blocks, pyrolytic carbon blocks