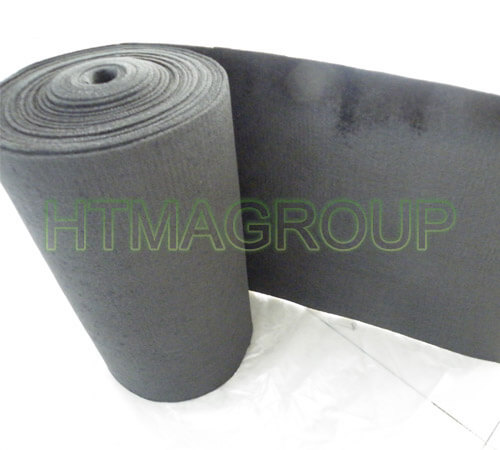

Due to the different raw blanket felt, the graphite felt is divided into 3 kinds: Petro coke-based, Pan-based graphite felt and Rayon-based

pan based graphite felt

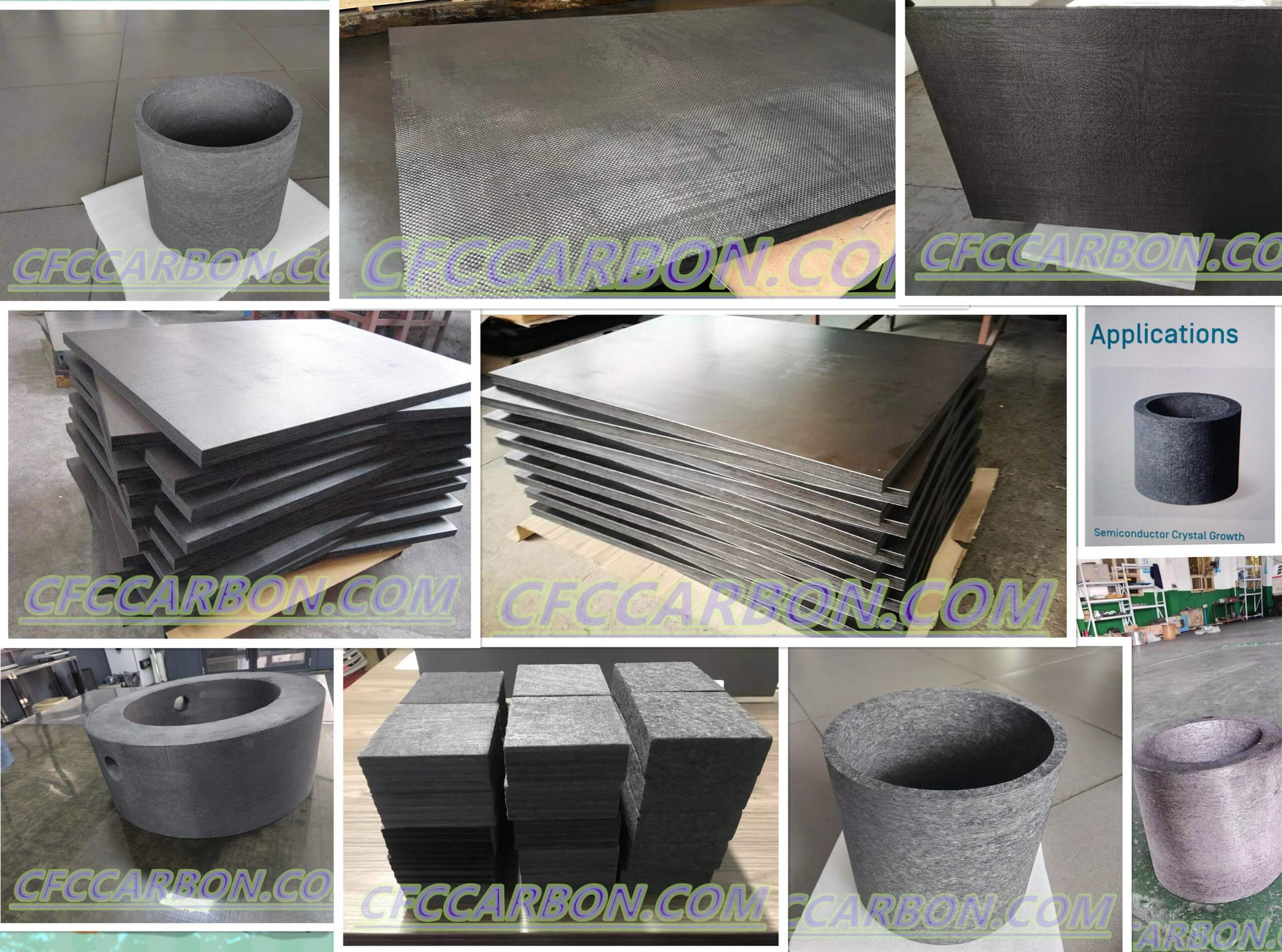

graphite felt. The main application is used as insulation, insulating materials for monocrystalline silicon smelting furnace. In the chemical industry, it can be used as high-purity corrosive chemical reagents filter material.

Definition of graphite felt

After high temperature above 2000 ℃ in the vacuum or inert atmosphere, the carbon felt turned into graphite felt. The carbon content is much higher than carbon felt, its 99% min. There is production and supply at end of the 1960s in the world. Due to the different raw blanket felt, the graphite felt is divided into 3 kinds: Petro coke-based, Pan-based graphite felt and Rayon-based graphite felt.

Japanese produces mainly Petro coke-based graphite felt, Europe and the United States are basically Rayon graphite felt, while in China, we usually use Pan-based material to produce graphite felt. The process is this: We cut Pan-based carbon felt or Rayon-based carbon felt into the required size, rolled into a cylindrical container made of graphite material, the

carbon graphite felt insulation soft hard rigid board short long fiber chopped material manufacturer factory China (B)

graphite container placed in high-temperature furnace (high-temperature furnace for graphite tube furnace, High-frequency induction furnace or other heating form of high-temperature furnace), vacuum or high pure inert gas protection to 100 ~ 300 ℃ / h heating rate to 2200 ~ 2500 ℃, then naturally cooled to 100 ℃ , then we got graphite felt.

Specification for Graphite Felt

Specifications Pan Graphite Felt Rayon Graphite Felt

Length (mm) ≥1500 ≥2000

Width (mm) 1000 ±200 1000 ±200

Thickness (mm) 3~ 15 3-15

Properties:

| Item | specification | ||

| Bulk density g/cm3 | 0.12~0.18 | ||

| Carbon content % | >99.9 | ||

| Thermal conductivity (1450℃)W/(mk) | 0.12~0.18 | ||

| Specific resistance Ωmm2/m | 0.16-0.21 | ||

| N/cm2 | portrait | ≥0.13 | |

| level | ≥0.06 | ||

| tensile strength Mpa | 0.14-0.30 | ||

| Ash content % | ≤0.02 | ||

| Processing temperature ℃ | 2200 | ||

|

Environment To use |

air ℃ | ≤400 | |

| vacuum ℃ | ≥2500 | ||

| Inertia air ℃ | ≥2800 | ||

Packing, storage and delivery:

Packed in plastic film, then packed in carton.

In the storage, don’t break the plastic film, At dry and ventilated places, preventing damps and rains

Shipper as non-dangerous goods.

Pan-based graphite felt stronger than the Rayon-based graphite felt, strong antioxidant capacity, but the flexibility is poor, and with higher bulk density. In addition to their high purity, high temperature, corrosion resistance, non-melting properties, there are flexible, can be folded, cut and can be used graphite yarn suture and other advantages. Graphite felt main application is used as a single crystal silicon smelting furnace insulation material. In the chemical industry can be used as high-purity corrosive chemical reagents filter material. The application temperature Graphite felt can up to 3000 ℃ or so in non-oxidizing atmosphere conditions.