Overcoming Performance Challenges in Carbon-Carbon Composite Coatings: Innovations and Solutions

By CFC Carbon R&D Team | Updated: May 17, 2025

1. What Are Carbon-Carbon (C/C) Composite Coatings?

Carbon-carbon composites (C/C) are advanced materials combining carbon fibers with a carbon matrix, renowned for their exceptional

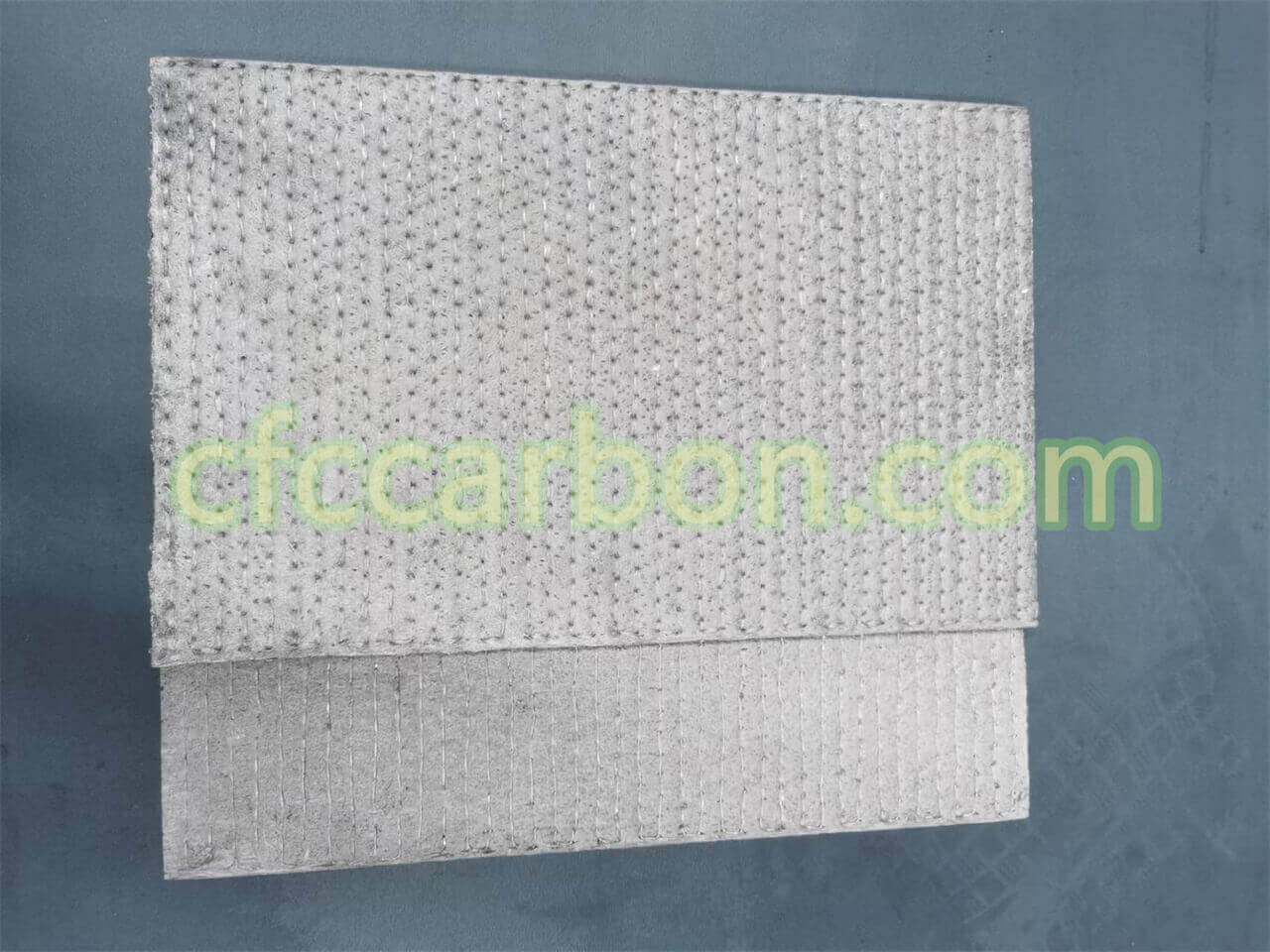

SiC coating carbon fiber composite material-CC-CFC (2)

strength-to-weight ratio and thermal stability above 2,300 K. However, their susceptibility to oxidation above 750 K necessitates protective coatings. C/C composite coatings are multilayer systems designed to shield the substrate from oxygen penetration and thermal degradation. These coatings typically include:

-

Transition layers (e.g., SiC) to mitigate thermal expansion mismatch

-

Ultra-high temperature ceramic (UHTC) outer layers (e.g., ZrB₂-SiC, HfC) for ablation resistance

-

Self-healing glass sealants (e.g., borate or phosphate-based) to repair microcracks

CFC Carbon Co., Ltd., a global leader in C/C manufacturing, emphasizes that coatings must balance oxidation resistance with mechanical compatibility to prevent spallation—a critical failure mode in aerospace applications.

2. Manufacturing, Classification, and Applications

Production Techniques

-

Chemical Vapor Deposition (CVD): Ensures uniform coating penetration for complex geometries (e.g., rocket nozzle liners).

-

Plasma Spray: Cost-effective for large-scale components like brake discs.

SiC coating carbon fiber composite material-CC-CFC (1)

-

Slurry Method: Ideal for doping nanostructures (e.g., carbon nanotubes) to enhance fracture toughness.

Product Categories

| Coating Type | Key Materials | Applications |

|---|---|---|

| Single-phase | SiC, ZrB₂ | Transition layers |

| Multiphase | ZrB₂-SiC, HfC-TaC | Hypersonic vehicle leading edges |

| Nanostructured | CNT-doped SiC | High-stress turbine components |

| Glass-sealed | B₂O₃, CSZP phosphates | Long-duration rocket engines |

Performance Characteristics

-

Thermal Stability: Withstand temperatures up to 2,200 K (e.g., HfC-ZrC coatings).

-

Oxidation Resistance: CSZP-based coatings reduce oxygen permeability by 40% compared to borate glasses.

-

Moisture Resistance: Modified phosphate glasses minimize hydrolysis-induced swelling.

3. Current Challenges and Solutions

Key Performance Issues

-

Coating Spallation

-

Cause: CTE mismatch between coating (e.g., SiC, α=4.5×10⁻⁶/K) and C/C substrate (α=1×10⁻⁶/K).

-

Solution: Gradient carbide transition layers (e.g., SiC/ZrB₂-SiC) distribute strain gradually.

-

-

Borate Glass Corrosion

-

Cause: High oxygen permeability (B₂O₃: ~10⁻⁷ cm²/s) accelerates SiO₂ dissolution in SiC coatings.

-

Innovation: Replace borates with low-permeability Ca₀.5Sr₀.5Zr₄(PO₄)₆ (CSZP) ceramics.

-

-

Moisture Sensitivity

-

Risk: Boric acid formation (H₃BO₃) weakens adhesion.

-

Mitigation: Hydrophobic dopants (e.g., graphene) in sealant layers.

-

-

Coating Thickness Trade-offs

-

Thin coatings (<50 µm) improve adhesion but degrade rapidly.

-

Thick coatings (>200 µm) resist corrosion but promote crack propagation.

-

4. Advancements in Coating Technology

Recent breakthroughs address these limitations:

-

Internal Oxidation Barriers: CFC Carbon’s proprietary SiC-whisker-reinforced C/C preforms slow substrate oxidation even if the outer coating fails.

-

Diamond-like Carbon (DLC) Coatings: Reduce friction coefficients by 60% in machining applications while maintaining high hardness (30–50 GPa).

-

Tantalum (Ta) CVD Coatings: Enhance compressive strength of porous C/C foams by 300% through strut reinforcement.

5. Future Directions

-

Multifunctional Coatings: Combine UHTCs with sensors for real-time health monitoring.

-

AI-Driven Process Optimization: Machine learning to predict CTE gradients and crack propagation.

-

Sustainable Manufacturing: CFC Carbon’s low-cost batch production techniques reduce energy use by 25%.

Conclusion

While current C/C coatings face challenges in spallation and environmental durability, innovations in material design (e.g., CSZP, DLC) and process engineering (e.g., nanostructured doping) are paving the way for next-generation solutions. CFC Carbon continues to lead this evolution, offering tailored coatings for aerospace, defense, and energy sectors.

Explore CFC Carbon’s Coating Solutions: www.cfccarbon.com

related news /articles:

High-Performance Coatings for Carbon fiber Carbon Composites

Advanced Coatings for Carbon fiber Carbon Composites

Introduction of high-temperature coatings on CC composite material

Advanced Protective Coatings for Carbon-Carbon Composites