Advanced Coatings for Carbon-Carbon Composites: Innovations in High-Temperature Protection

By CFC CARBON CO., LTD | Updated May 16, 2025

1. What Are Coatings on Carbon-Carbon Composites?

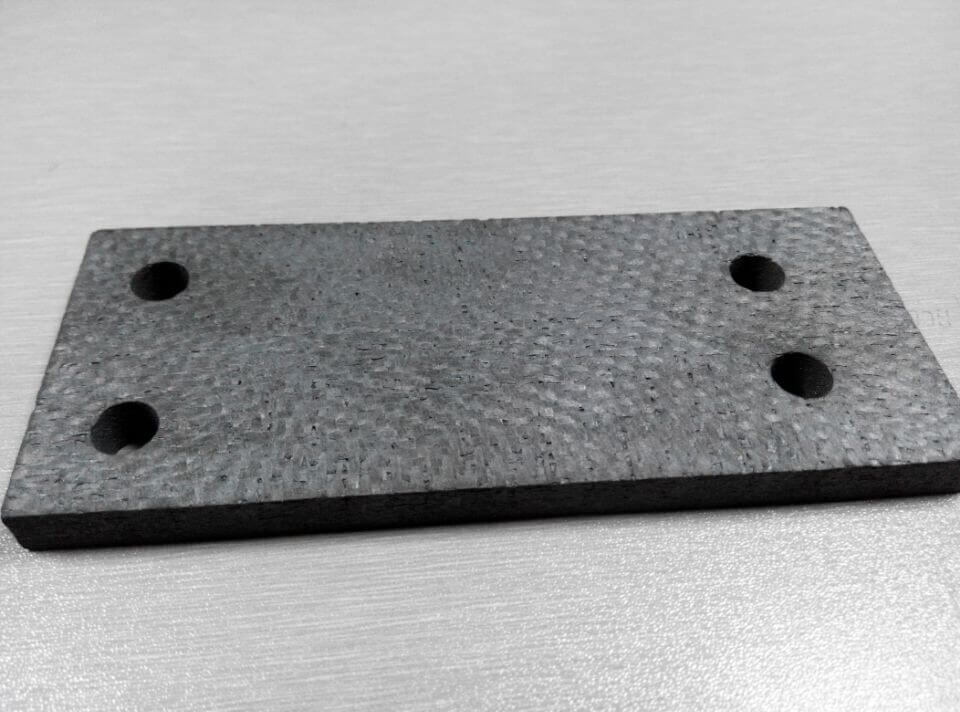

SiC coating carbon fiber composite material-CC-CFC (2)

Carbon-carbon (C/C) composites, known for their lightweight properties and exceptional strength at extreme temperatures, are widely used in aerospace, hypersonic vehicles, and thermal protection systems. However, their susceptibility to oxidation above 400°C necessitates specialized coatings to ensure durability115. These coatings act as protective barriers against chemical erosion, thermal cycling, and oxygen diffusion, enabling C/C composites to perform reliably in environments exceeding 1600°C15.

At CFC CARBON CO., LTD, we develop multi-layered coating systems that combine ceramics, refractory metals, and glass-forming sealants to address these challenges. For instance, our SiC-coated C/C plates exhibit unmatched thermal stability up to 1600°C, making them ideal for semiconductor manufacturing and aerospace components15.

2. Manufacturing Methods and Product Classification

Production Techniques

-

Chemical Vapor Deposition (CVD): A gold-standard method for creating ultra-thin, adherent ceramic coatings like SiC and Si3N4. CVD ensures uniform coverage and minimal impact on fiber mechanical properties115.

-

Vacuum Plasma Spray (VPS): Ideal for rapid deposition of high-melting-point materials such as HfC. By integrating a SiC buffer layer, VPS achieves 110-μm-thick coatings in just 8 minutes while mitigating thermal expansion mismatches5.

-

Electrodeposition (ED): Used for noble metal coatings like iridium (Ir), which offers impermeability to oxygen and stability up to 2110°C. ED is paired with rhenium interlayers to resolve CTE mismatches10.

-

Slurry Painting: A cost-effective repair method for damaged SiC coatings. By blending Si, Al2O3, and SiC powders, this technique restores oxidation resistance with a mere 0.32% weight loss after 10 hours at 1773K14.

Product Categories

-

Ceramic Coatings

-

SiC/Si3N4 Coatings: Primary oxygen barriers for temperatures up to 1700°C. Their glassy SiO2 byproducts self-seal

C-SIC

microcracks during thermal cycling115.

-

HfC Coatings: Designed for ultra-high-temperature regimes (>1800°C), HfC’s thermal ablation resistance is enhanced by SiC interlayers to prevent delamination5.

-

-

Noble Metal Coatings

-

Iridium (Ir): With a melting point of 2430°C, Ir coatings are critical for combustion chambers and reusable thermal protection systems. NASA mission simulations confirm their viability in extreme environments110.

-

-

Hybrid Systems

-

Multi-layered structures combining SiC outer layers with borate glass sealants or Ir bond layers. These systems address challenges like moisture sensitivity and oxygen permeability115.

-

3. Performance Characteristics and Applications

Key Advantages

-

Thermal Stability: SiC coatings withstand 1600°C, while Ir coatings excel beyond 2000°C1015.

-

Oxidation Resistance: HfC-coated composites show 74.79% lower mass loss than uncoated counterparts after thermal ablation5.

-

Mechanical Integrity: Submicron coatings preserve 90% of carbon fiber strength, critical for structural aerospace components1.

Industry Applications

-

Aerospace: Reusable thermal shields for spacecraft and hypersonic vehicle airframes115.

-

Energy: Components for high-temperature reactors and semiconductor processing equipment15.

-

Defense: Oxidation-resistant combustion chambers and missile guidance systems10.

4. Overcoming Technical Challenges

Current coating systems face limitations such as:

-

Thermal Expansion Mismatch: Addressed via SiC buffer layers in HfC-VPS coatings5.

-

Borate Glass Limitations: Replaced by SiO2-based sealants for temperatures above 1550°C1.

-

Coating Delamination: Optimized CVD processes at CFC CARBON ensure tighter bonding through patented technologies15.

5. Future Innovations

Research at CFC CARBON focuses on:

-

Ultrahigh-Temperature Coatings: Combining Ir with SiO2 layers to isolate carbon substrates while accommodating CTE differences1.

-

AI-Driven Deposition: Enhancing CVD/VPS precision for complex geometries.

-

Sustainable Repair Methods: Expanding slurry painting techniques to reduce material waste by 60%14.

Why Choose CFC CARBON?

As a leader in carbon composite solutions, we offer:

-

Customized coatings (SiC, TaC, Ir) tailored to operational demands.

-

Patented adhesion technologies for crack-resistant surfaces15.

-

Global technical support from our Beijing-based R&D center.

Contact us at potter@cfccarbon.com or visit www.cfccarbon.com for material specifications and case studies.

related news /articles:

Matrix inhibition / coating of CC composite material

Ultrahigh-temperature coatings on carbon carbon composite

Carbon fiber reinforced silicon carbide composites (C/SiC, C/C-SiC)-(2)-application