Mesophase pitch-based carbon fibers are an attractive precursor candidate for carbon fibers because of the high availability of low-cost raw pitch. There are several reasons why the mesophase pitch process should produce a lower cost, high-performance fiber. First, the starting material (petroleum or coat-tar pitch) costs 40-50 percent less than the monomers used to form PAN. Second, because pitch based carbon fiber begins with a structure closer to graphite than PAN does, less energy is required to convert it to graphite. Because of this, lower carbonization temperatures and/or shorter carbonization times are required in the production of pitch-based carbon fibers. Third, mesophase precursor fiber contains a smaller percentage of nitrogen, hydrogen, and other noncarbon elements than PAN precursor fiber and, therefore, less material is driven off during carbonization. Because of this, the percent yield is approximately 75 percent for mesophase pitch precursor fiber compared with only 40-45 percent for PAN precursor fiber.

Mesophase Pitch

Mesophase pich can be produced by the thermal or catalytic polymerization of a suitable petroleum or coal-tar pitch. When a highly aromatic pitch, such as a decent oil pitch, is heated to temperatures of 400C to 450C for approximately 40hr, 45-65 percent of it will transform from an isotropic material to an optically anisotropic fluid phase-a mesophase or liquid crystal. A free-radical mechanism is believed to be responsible for polymerization of the carbonaceous material. Another method is so use solvents such as benzene, heptane, and toluene to first

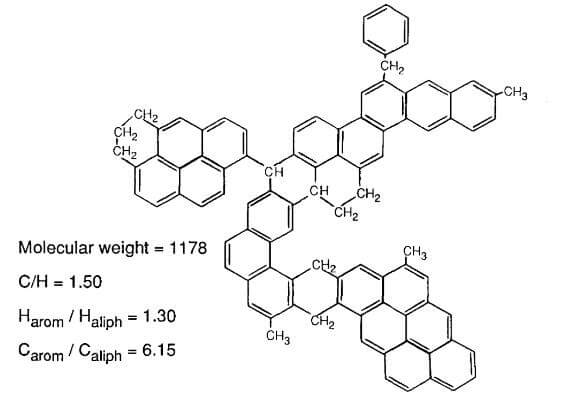

Typical polynuclear aromatic hydrocarbon in mesophase

extract a portion of the isotropic pitch. The solvent insoluble portion can be converted to an anisotropic pitch by heating to between 230C and 400C for less than 10 minutes. The anisotropic, or oriented, phase is composed of stacked, polynuclear aromatic hydrocarbon molecules. These molecules tend to be disc-shaped with an average molecular weight of approximately 1000. The molecular structure of the mesophase produce from coal-tar pitch is characterized by higher aromaticity, whereas the structure of the petroleum-derived mesophase is more open because of its higher content of aliphatic side chains. Figure 8 shows the structure of a typical polynuclear aromatic hydrocarbon in mesophase. Initially, small spheres of mesophase form in the isotropic pitch when heated for an adequate time at a sufficiently high temperature. Upon further heating, the concentration of the mesophase spheres increases and caused the spheres to collide and coalesce, creating a mosaic-like, nematic liquid-crystal structure.

Mesophase products that have a high average molecular weight and no side groups or small molecular components to cause disordering often decompose before becoming fluid enough to flow. Because of this, the

pitch coke carbon composite

mesophase used to melt spin fibers is normally a mixture of high molecular weight molecules that still have a small number of side groups. Therefore, commercial mesophase precursors have certain characteristics of both mixtures and solutions: they soften over a range of temperatures and orient under an applied stress.

Numerous studies have concluded that, in general, the flow behavior of mesophase pitchs is shear thinning at low shear rates but approaches Newtonian at high shear rates. In addition, it is the large response time for changes in flow rate which indicates that mesophase pitch is somewhat viscoelatic. However, the most unusual characteristic of mesophase pitch is the extreme temperature dependency of its viscosity. Even though mesophase pitch can be formed into fibers by conventional melt-spinning techniques, extremely precise temperature control is required.

related news /articles:

Introduction of manufacturing of carbon fibers-Pan-based carbon fibers

Microstructure of Pitch matrix CC composite

Recommended terminology for the description of carbon as a solid (1)