Introduction:

In the early years of carbon fibers, there was an unfortunate tendency to specify carbon fibers made at about 2800K as graphite fibers which, in the majority of cases, is simply not crystalline order is confirmed. It is considered, at this stage, relevant to define the terminology for the

carbon graphite felt insulation soft hard rigid board short long fiber chopped material manufacturer factory China (s)

various forms of solid carbon and associated products which are mentioned in this book and requisite information has been used from The International Union of Pure and Applied Chemistry (IUPAC) recommendations.

Description of terms:

- ACTIVATED CARBON is a porous CARBON MATERIAL, a CHAR which has been subjected to reaction with gases, sometimes with the addition of chemicals, before, during, or after CARBONIZATION.

- AMORPHOUS CARBON is a CARBON MATERIAL without long range crystalline order.

- BROOKS AND TAYLOR STRUCTURE IN THE CARBON ACEOUS MESOPHASE refers to the structure of the anisotropic spheres which precipitate from isotropic PITCH during pyrolysis. The structure of the spheres consists of a lamellar arrangement of aromatic molecules in parallel layers, which are perpendicular to the polar axis of the sphere and which are perpendicular to the mesophase-isotropic phase interphase.

- BULK MESOPHASE is a continuous anisotropic phase formed by the coalescence of mesophase spheres. BULK MESOPHASE retains fluidity and is deformable in the temperature range up to about 770K, and transforms into GREEN COKE by further loss of hydrogen or other low molecular weight species.

- CARBON is the sixth element of the Periodic Table of Elements. Note: for description of the various types of CARBON AS A SOLID, the term CARBON should be used only in combination with an additional noun or a clarifying adjective.

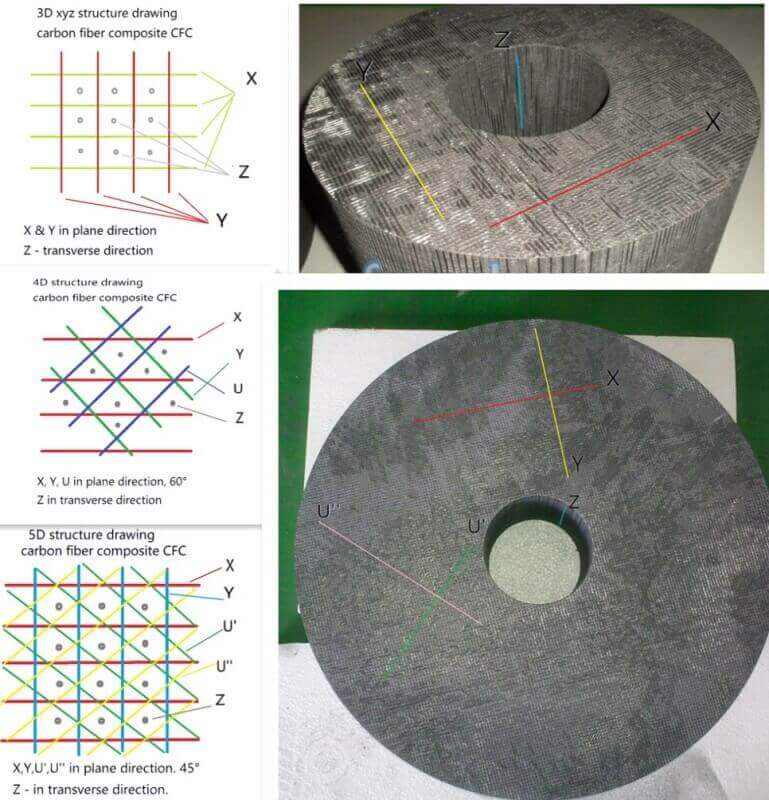

3D 4D 5D carbon fiber composite CFC structural diagram drawing material (1)

- CARBON BLACK is an industrially manufactured COLLOIDAL CARBON material, in the form of spheres as well as of their fused aggregates, with sizes below 1000 nm. Note: For historical reason, CARBON BLACK is popularly, but incorrectly, regarded as a form of SOOT.

- CARBON-CARBON COMPOSITE is a carbon fiber reinforced carbon matrix material. The carbon matrix phase is typically formed by solid, liquid or gaseous pyrolysis of an organic precursor material. The matrix is either a GRAPHITIZABLE CARBON or NON-GRAPHITIZATION CARBON, and the carbonaceous reinforcement is fibrous. The composite may also contain other components in particulate or fibrous forms. Click here to visit the product informations of carbon-carbon composite.

- CARBON FIBERS are fibers (filaments, tows, yarns, rovings) consisting of at least 92% CARBON, usually in the NON-GRAPHITIC state.

- CARBON FIBERS HT are CARBON FIBERS with values of Young’s Modulus in the range 150-275 or 300 Gpa. The term HT, referring to high tensile strength, was previously applied because fibers of this type display the highest tensile strengths. Note: The disposition of boundaries between the fiber types is somewhat arbitrary. The tensile strength of CARBON FIBERS is, however, flaw controlled and therefore, the measured values increase strongly as the diameter of the filaments is decreased.

- CARBON FIBERS TYPE HM (HIGH MODULUS) are CARBON FIBERS with a value of Young’s modulus (tensile modulus) larger than 300 Gpa. Here again, tensile strength is influenced by flaws in the fiber.

To be continue.

related news /articles:

Recommended terminology for the description of carbon as a solid (2)

Recommended terminology for the description of carbon as a solid (5)

Recommended terminology for the description of carbon as a solid (3)

General considerations and terminology of graphite