The degraded property layers can be treated as additional subcell regions and the previously described procedure can be applied. However,

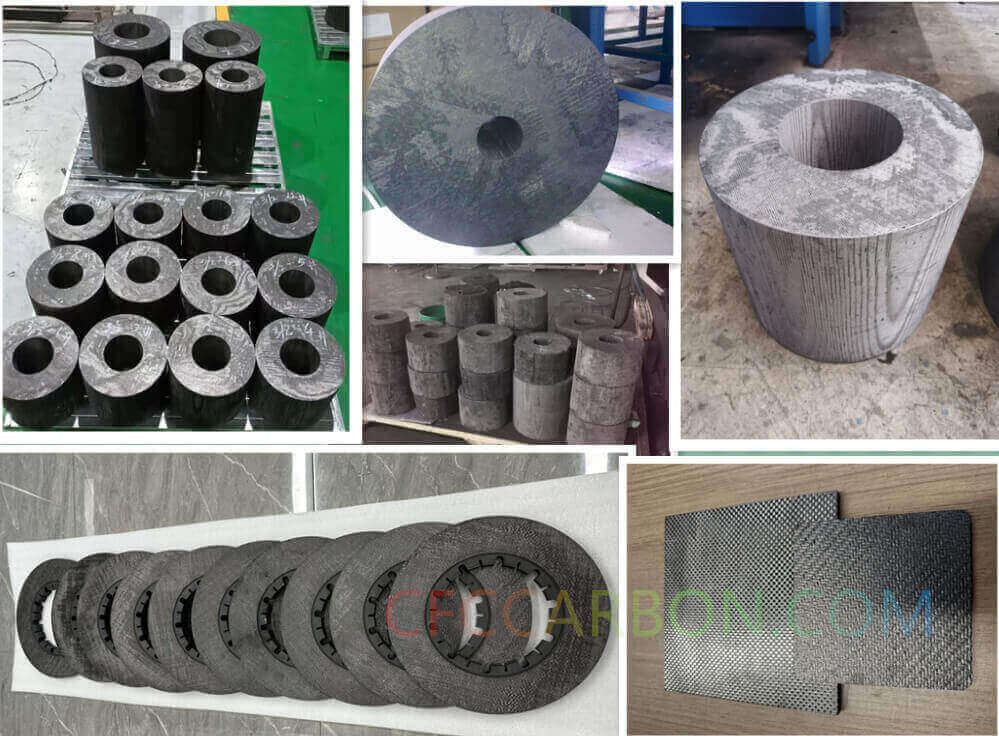

2D 3D 4D 5D carbon fiber composite material manufacturer factory -airplane brake disc plates sheets U L profiles-2D(6)

there is some question as to influence of using only admissible displacement fields, which are representative of upper-bound results. Hence, the approach to this problem considered both upper and lower bounds. Approximate solutions for the boundary value problem were developed using variational techniques that yield upper and lower bounds for the effective thermoelastic properties as well as approximate values of the strains and stresses in various subregions for a given applied stress state. For upper-bound formulations, admissible displacement fields are assumed with unknown parameters, and the potential energy expression in the representative volume element is minimized to determine the values of these parameters. From the theorem of minimum potential energy, the potential energy for the assumed displacement field is greater than or equal to the actual potential energy that yields the upper bound for the elastic moduli. In the lower-bound formulation, admissible stress field are assumed, and the complementary energy is minimized to obtain the lower bounds via the theorem of minimum complementary energy. Thus, the model provides both upper- and lower-bound solutions for the thermoelastic properties of the RVE and, hence, the composite.

Each degraded property region is considered to have a reduced stiffness. This stiffness may differ for each stress component between each pair of subcell regions, and reduced stiffness may be normalized to define an efficiency for stress transfer. By assuming that the stiffness of the degraded regions are the same on each principal plane of the material, the unknown efficiencies can be reduced to six in number, namely, the efficiencies for tension and compression and for the three principal shear directions Sij. The DCAP computer formulation includes these six quantities. However, a single efficiency S may be utilized by simply assuming that all efficiencies are equal. A single unit cell efficiency S has been found to agree with limited experimental data on CC composite materials.

The efficiencies are an approximate measure of the reduction of the composite Young’s modulus from the value of the modulus when no weak regions are present. If one assumes that the weak regions contains flat disk-shaped stress-free regions, then the efficiency is also an approximate measure of the fraction of the contact area between the subregions that are considered perfect in transferring stress. Therefore, when Sij=0, all the weak surfaces perpendicular to the coordinate direction are fully cracked. When Sij=1, no cracks exist in the weak surface perpendicular to direction i. The efficiencies are similarly approximate measures of the reduction of shear modulus Gij or the fraction of the contact areas effective in transferring shear stress Tij. cfccarbon.com

Details of the analytical formulations and assumed displacements within the unit cell have been given in reference 23. The upper- and lower-bound formulations were also shown to give very close results for most weave configurations; because of this, the upper-bound results are sufficient for most purposes.

related news /articles:

Degraded properties model of carbon-carbon (CC) composite

Compressive stiffness and strength after thermal shock on C/C composites

Applications of carbon-carbon composite (2)

Development concerns of Carbon-carbon composites as recuperator materials (4)