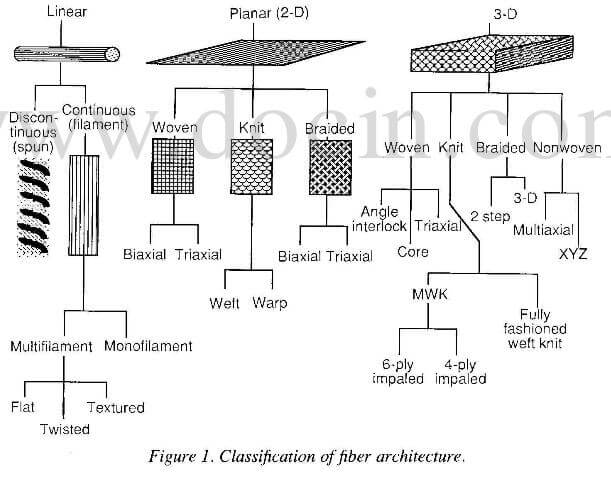

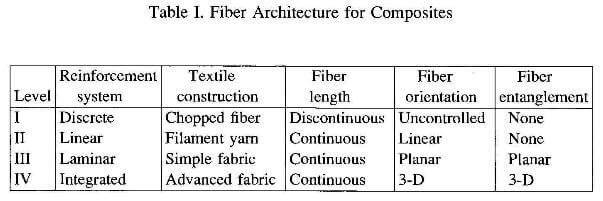

On the basis of structural integrity and fiber linearity and continuity, fiber architecture can be classified into four categories: discrete,

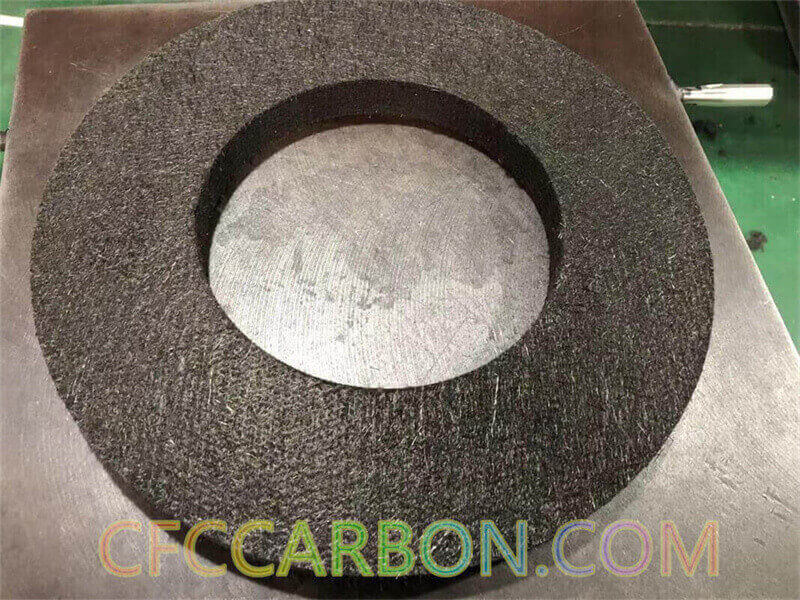

2.5D needle punch CFC airplane Brake disc-carbon fiber composite preform-preforming-Prefab T700 12K (1)

continuous, planar-interlaced (2D), and fully integrated (3D) structures. In the following table, the nature of the various levels of fiber architecture is summarized.

The first category of fiber architecture is a discrete fiber system, such as a whisker or fiber mat, which has no material continuity. The orientation of the fibers is difficult to control precisely, although some aligned discrete fiber systems recently have been introduced. The structural integrity of the fibrous preform is derived mainly from inter-fiber friction. The strength translation efficiency, or the function of fiber strength translated to the fibrous assembly of the reinforcement system, is quite low.

The second category of fiber architecture is the continuous filament or unidirectional system. This architecture, which has the highest level of fiber continuity and linearity, has the highest level of property translation efficiency and is very suitable for filament-wound and angle-ply-tape layup structures. The drawback of this fiber architecture is its intra- and inter laminar weakness because of the lack of in-plane and out-of-plane yarn interlacings.

3D 4D CFC carbon fiber composite preform-preforming-Prefab (1)

A third category of fiber reinforcement is the planar interlaced and interloped system. Although the intra-laminar failure problem associated with the continuous filament system is addressed with this fiber architecture, the matrix strength limits the interlaminar strength because of the lack of through-the-thickness fiber reinforcement.

The fully integrated system forms the fourth category of fiber architecture wherein the fibers are oriented in

classification of fiber architecture

various in-plane and out-of-plane directions. With the continuous filament yarn, a 3D network of yarn bundles is formed integrally. The most

3D 4D CFC carbon fiber composite preform-preforming-Prefab (2)

attractive feature of the integrated structure is the additional reinforcement in the through-the-thickness direction that makes the composite virtually delamination-free. Another interesting aspect of many of the fully integrated structures such as 3D woven, knits, and braids is their ability to assume complex structural shapes.

Besides having a strong influence on the directional contribution of fiber properties to the composite material, fiber architecture also dictates the ease of matrix placement in composite processing. For this review, we concentrate on the linear, planar, and 3D fiber assemblies. Figure 1 provides an overview of these three categories of fiber architecture showing the sub-groups of each class. A detailed description of the classes of fiber architecture follows.

fiber architecture for carbon composites

related news /articles:

Different structures of 3D carbon carbon composite | C/C composite

Filament wound carbon carbon (C/C) composite

3D Carbon fiber composite | CFC material manufacturer in China

Continuous and discontinuous carbon fiber composites