How carbon brushes work?

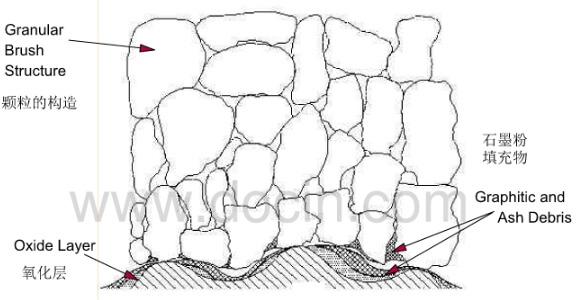

What is commutator film: you can see Fig.3-oxide layer

Fig.3-oxide layer

To enhance film formation, the commutator should be turned to a surface roughness of 35 to 60 uin. A film will not form properly if the commutator surface is too smooth.

A thin, uniform film having a brown/grey patina is desired.

- Overfilming- a thick, black film will increase contact drop and cause excess spaking and high electrical wear.

- Underfilming- a very thin or non-existent film will result in high frictional wear and may degrade commutation.

Base filming characteristics is normally controlled by the brush grade.

Contact drop vs current density:

What is brush wear?

What is electrical wear?

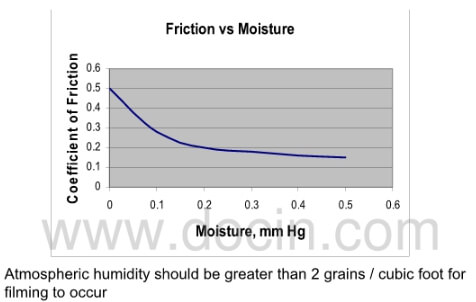

fig.4-friction vs moisture

- Voltage pulses cause rapid increases in temperature at the conducting spots in the brush.

- Small pieces of the brush are expelled, causing wear.

- Higher voltages cause an electric arc to form, causing extensive damage to brush and commutator. The contact spots are heated to 2500-3000°

Wear rate increases with current density.

Frictional wear:

- Shearing of graphite during sliding of brush face over commutator.

- Rapid during initial film formation.

- Greatly increased under some atmosphere and temperature conditions.

- Higher for high-metal content brushes having little graphite.

Both electrical and friction wear are increased by high commutator bar-to-bar profile and high TIR.

Effect of atmosphere on friction of graphite, see fig.4-friction vs moisture.

Low temperature:

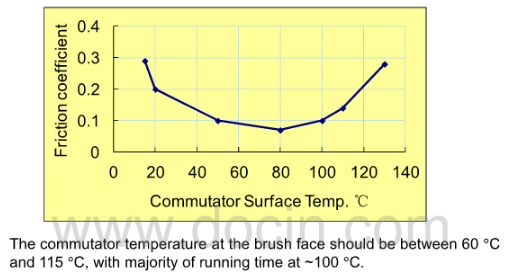

Thermal stability of copper graphite brush is key to long life and stable performance.

fig.5-brush face temperature

Under low temperature, it is difficult to build good film between brush and commutator surface, which caused fast mechanical friction; at the same time, the sparkle condition is bad.

Low temperature- low humidity- brush wear rapidly

Low temperature means low humidity, low humidity means the sub-pressure of water vapour is to low that the H2O molecular complete desorption from film.

High coefficient of friction- wear quickly.

High humidity- over filming.

related news /articles:

Carbon brush and brush materials-electrical carbon (1)-characteristics

New modernization technology— Carbon brush material

Carbon Brush | Electric Brush Guide by CFCCARBON LTD

Resin graphite material | carbon brush materials- manufacturer in China