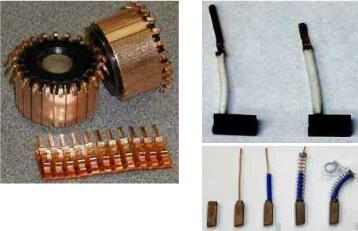

carbon brush – commutator interface: see Fig.1.

Fig.1-carbon brush and commutator interface

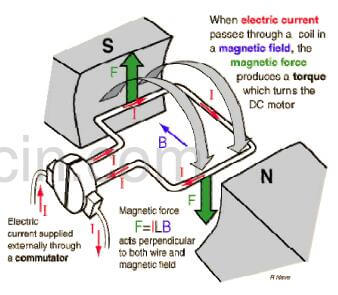

what is commutation: The process of current reversal in armature coils which ideally take place when the coils are cutting the minimum lines of magnetic flux-the neutral position. see Fig.2, when electric current passes through a coil in a magnetic field, the magnetic force produces a torque which turns the DC motor; Electric current applied externally through a commutator; magnetic force F=ILB acts perpendicular to both wire and magnetic field.

Why we choose carbon brush? what is the characteristics /advantages of carbon brush? see bellow:

-High electrical and thermal conductivity

-Solid lubricant

-Withstands high temperature

Fig.2-how commutator works

-Low density

-Non-welding

-Low coefficient of thermal expansion

-Low cost

-Machineable/moldable

-High resistance carbon

The above advantages are specially belongs to electrical carbon.

Commutator materials: one type is copper, and another is carbon.

Copper commutator:

–Used on nearly all FHP motors

–Copper No’s. CA105/CA107 (Cu with ~0.09% silver)

Excellent electrical conductivity; resistanct to softening during fusing; develops stable film on surface contacting brush.

Carbon commutator:

-Used for automotive fuel pumps; Hot molded onto copper shell; Excellent life and motor performance;

related news /articles:

Carbon brush and brush materials-electrical carbon (2)

New modernization technology— Carbon brush material

Carbon Brush | Electric Brush Guide by CFCCARBON LTD

Resin graphite material | carbon brush materials- manufacturer in China