Innovative Graphite Solutions for Industrial Heat Transfer

In the realm of corrosion-resistant heat exchange systems, resin extruded graphite tubes have emerged as a game-changer. As a leading

graphite pipes for heat exchangers (4)

manufacturer in China, CFCCARBON LTD specializes in producing high-performance phenolic resin-extruded graphite tubes tailored for demanding industrial applications. Combining the superior thermal conductivity of graphite with the durability of resin, these tubes offer unmatched efficiency in harsh chemical environments.

What Are Resin Extruded Graphite Tubes?

Resin extruded graphite tubes are manufactured through a precision-driven process:

-

Material Synthesis: A blend of phenolic resin and high-purity graphite powder is homogenized.

-

High-Temperature Graphitization: The mixture undergoes graphitization at temperatures exceeding 400°C, ensuring structural stability and enhanced thermal properties.

-

Extrusion Molding: Advanced extrusion technology enables the production of seamless tubes with lengths up to 7,500mm – significantly longer than traditional machined graphite tubes.

Unlike machined alternatives (carved from solid graphite blocks), resin-extruded tubes excel in scalability and cost-effectiveness, particularly for large-scale heat exchanger projects.

Technical Advantages of CFCCARBON LTD’s Graphite Tubes

-

Superior Thermal Conductivity: With heat treatment at 300°C, our tubes achieve a thermal conductivity of 30-40 W/(m·K), outperforming stainless steel and non-metallic competitors.

-

Robust Pressure Resistance: Bursting pressure up to 6.8 MPa, backed by a 30-minute penetrability test under 1 MPa with zero leakage.

-

Precision Dimensions: Standard OD/ID ranges include 32/22mm, 37/25mm, and 51/38mm, with diameter tolerances as tight as ±0.1mm.

Key Applications Across Industries

CFCCARBON LTD’s resin graphite tubes are widely adopted in sectors requiring reliable heat transfer under corrosive conditions:

-

Chemical & Chlor-Alkali Processing: Resistant to hydrochloric acid and chlorine environments.

-

Pharmaceuticals: Ensures contamination-free heat exchange in reactors and condensers.

-

Environmental Protection: Used in scrubbers and wastewater treatment systems.

-

Metallurgy & Electroplating: Withstands high-temperature acidic baths.

For more industry-specific solutions, explore our Graphite Tubes for Heat Exchangers.

Why Choose CFCCARBON LTD?

-

Custom Manufacturing: Capable of producing tubes up to 7,500mm with rapid turnaround.

-

Comprehensive Product Line: From graphite blocks to heat exchanger plates, we provide end-to-end solutions.

-

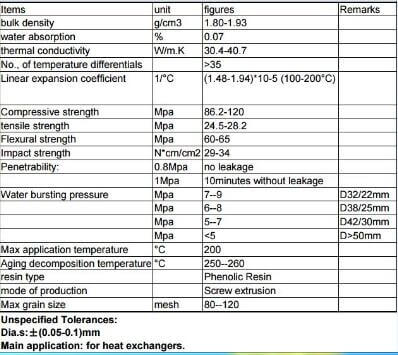

data sheet-heat exchanger graphite pipes

Cost Efficiency: Competitive pricing with exclusive discounts for bulk orders in 2024.

Technical Specifications at a Glance

| Parameter | Specification |

|---|---|

| Max Length | 7,500mm |

| OD Range | 12–56mm |

| Thermal Conductivity | 30–40 W/(m·K) |

| Burst Pressure | 6.8 MPa |

Partner with a Trusted Manufacturer

With over two decades of expertise, CFCCARBON LTD is committed to delivering precision-engineered graphite components. Our facility in Beijing’s Yizhuang Economic Development Zone integrates cutting-edge extrusion technology with stringent quality control.

Contact Us Today for a Quote: