Introduction to Graphite Tubes in Industrial Applications

Graphite tubes, also known as graphite pipes, are critical components in chemical, pharmaceutical, and energy industries due to their exceptional thermal conductivity, corrosion resistance, and structural stability. As a premier graphite tubes manufacturer in China, CFCCARBON LTD specializes in producing two distinct types of graphite tubing solutions: machined graphite tubes and extruded resin graphite tubes. This article focuses on our advanced resin graphite tubes designed for heat exchanger systems.

1. Two Types of Graphite Tubes: Machined vs. Extruded

resin graphite pipes for heat exchangers-8

-

Machined Graphite Tubes: Fabricated from high-purity molded, isostatic, or vibration-compacted graphite blocks, these tubes are precision-engineered for applications requiring tight tolerances.

-

Extruded Resin Graphite Tubes: Produced by blending premium resin binders with graphite powder and undergoing high-temperature graphitization, these tubes excel in heat exchangers with lengths up to 7,500mm—far exceeding standard machined tubes.

Explore our graphite block manufacturing process.

2. Why Choose Resin Graphite Tubes for Heat Exchangers?

Resin graphite tubes dominate heat exchanger applications for three key reasons:

-

Extended Length Capacity: With production lengths up to 7.5 meters, they reduce joint points and enhance system integrity.

-

Superior Pressure Resistance: Bursting pressure up to 6.8MPa ensures reliability in high-stress environments.

-

Impermeability Guarantee: Passes a 30-minute penetrability test under 1MPa pressure with zero leakage.

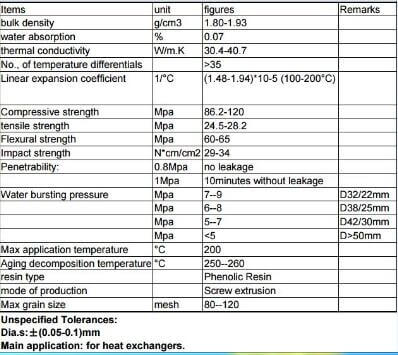

data sheet-heat exchanger graphite pipes

3. Technical Specifications of CFCCARBON’s Resin Graphite Tubes

| Parameter | Specification |

|---|---|

| Outer Diameter (OD) | 32mm, 37mm, 51mm (customizable) |

| Inner Diameter (ID) | 22mm, 25mm, 38mm (customizable) |

| Length | 0–7,500mm (±0.1mm tolerance) |

| Operating Pressure | ≤1.5MPa (standard) |

| Temperature Range | -20°C to 170°C (higher grades available) |

For detailed CAD drawings, visit Graphite Tube Dimensions.

4. Manufacturing Excellence at CFCCARBON LTD

As a trusted graphite heat exchanger components supplier, we combine cutting-edge extrusion technology with strict quality control:

-

Automated Production Lines: Ensure consistency across large-scale orders.

-

Customization Flexibility: Tailor OD/ID ratios, lengths, and resin formulations to match client requirements.

-

End-to-End Testing: Every batch undergoes penetrability, pressure, and thermal shock validation.

5. Applications Beyond Heat Exchangers

While resin graphite tubes are widely used in shell-and-tube heat exchangers, they also serve in:

✔ Acid condensation systems

✔ High-purity gas cooling units

✔ Nuclear reactor cooling loops

✔ Waste heat recovery setups

Discover more industrial applications.

6. Partner with a Certified Graphite Solutions Provider

CFCCARBON LTD holds ISO 9001 certification and serves clients across 30+ countries. Our advantages include:

✅ Fast Delivery: 15–30 days for standard specifications.

✅ Technical Support: Free consultation on tube-to-header sealing designs.

✅ Competitive Pricing: Economies of scale from vertically integrated production.

Conclusion: Optimize Your Heat Transfer Systems Today

Whether you need compact machined tubes or ultra-long extruded resin graphite pipes, CFCCARBON LTD delivers solutions that outperform metals and ceramics in corrosive environments. Contact us for samples, quotes, or technical datasheets:

📧 Email: sales@cfccarbon.com

🌐 Website: www.cfccarbon.com