1. What is a C/C Mould?

A Carbon-Carbon (C/C) composite mould is a high-performance tooling solution engineered from carbon fibers reinforced within a carbon matrix. Unlike traditional graphite or metal moulds, C/C composites combine exceptional thermal stability (up to 3,000°C in inert

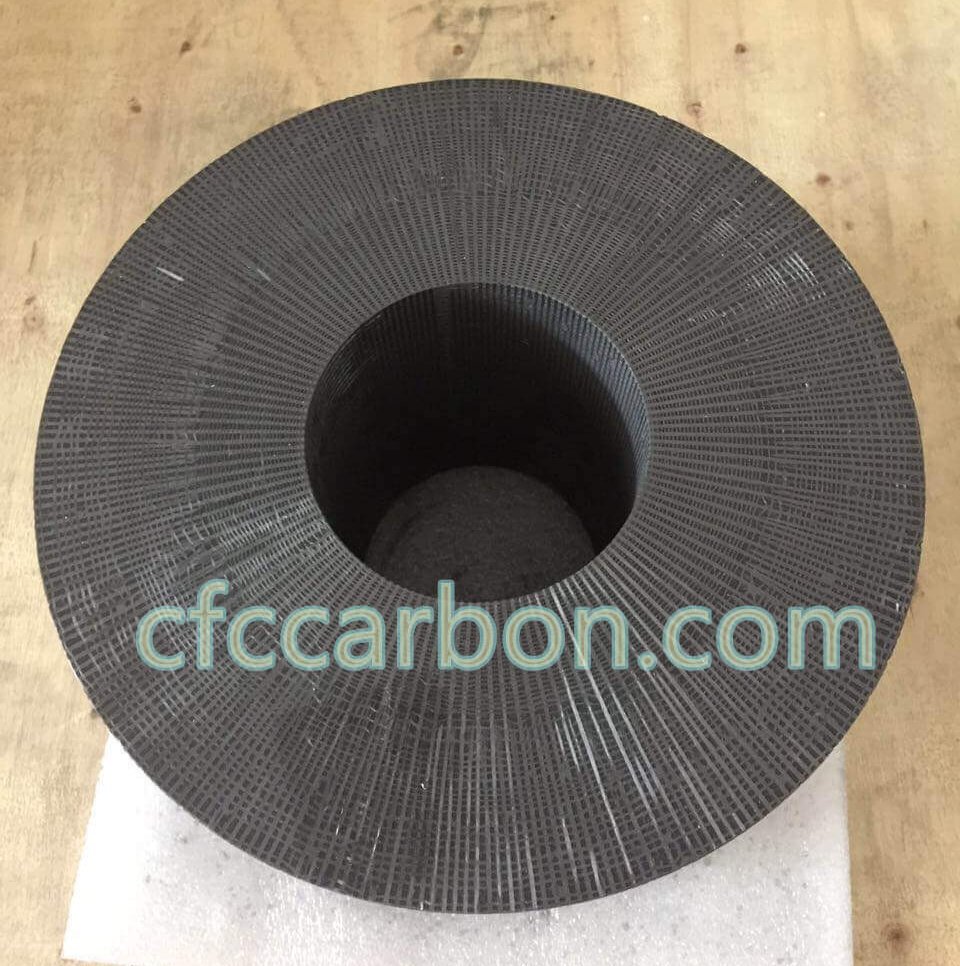

high performance carbon fiber composite mould-2D structure-material manufacturer China

environments), ultra-low thermal expansion, and superior mechanical strength, making them ideal for extreme-temperature industrial processes such as hot pressing, aerospace component fabrication, and advanced ceramics sintering34. These moulds are manufactured using advanced techniques like 2D winding, 3D weaving, or 4D structuring to optimize fiber alignment and density3.

2. Manufacturing and Product Classification

Production Process

C/C moulds are created through a multi-step process:

-

Preform Creation: Carbon fibers are arranged in 2D, 3D, or 4D architectures to achieve desired mechanical properties.

-

Matrix Infiltration: Pyrolytic carbon or resin is infused into the fiber structure under high pressure.

-

Hot Pressing: The composite undergoes high-temperature compression (up to 2,800°C) to densify the matrix and enhance

3D 4D 5D Hoops, Loop, weaving, stucture, drawing, carbon fiber, carbon, composite, CFC, CC, manufacturer, China, (1)

durability47.

Product Categories

CFC Carbon categorizes C/C moulds into three industrial-grade types based on performance needs:

-

Standard 2D Moulds: Cost-effective with high oxidation resistance, suitable for temperatures up to 2,200°C and diameters ranging from 100mm to 2m4.

-

High-Density 3D Moulds: Designed for aerospace applications, these withstand 2,800°C and feature ultra-low CTE (<3×10⁻⁶/K) for zero thermal deformation34.

-

Quick-Cycle Moulds: Optimized for rapid heating/cooling (30% faster production), ideal for small-scale components under 500mm diameter4.

3. Key Applications Across Industries

C/C moulds are revolutionizing manufacturing in critical sectors:

-

Aerospace: Turbine blades, rocket nozzles, and heat shields requiring dimensional stability at extreme temperatures4.

-

Automotive: Lightweight brake discs and EV battery components for enhanced energy efficiency4.

-

Industrial Ceramics: Sintering silicon nitride and zirconia with 52% fewer defects compared to graphite moulds4.

-

Medical: Precision tools and implants benefiting from biocompatibility and wear resistance3.

4. Performance Advantages Over Traditional Materials

C/C composites outperform conventional mould materials in multiple metrics:

-

Longevity: 5–10× longer lifespan than graphite under cyclic thermal stress4.

-

Thermal Conductivity: Even heat distribution reduces warping, lowering energy consumption by 18%4.

-

Mechanical Strength: Flexural strength exceeds 100 MPa, with ash content <50 ppm for purity-critical applications3.

-

Sustainability: Fully recyclable, reducing waste and aligning with circular economy goals4.

5. Technical Specifications and Pricing

| Type | Max Temperature | Size Range | Density (g/cm³) | Price Range |

|---|---|---|---|---|

| Standard 2D | 2,200°C | 100mm–2m | 1.6–1.9 | $800+ |

| High-Density 3D | 2,800°C | Customizable | 1.5–1.9 | $2,500+ |

| Quick-Cycle | 1,800°C | <500mm | 1.5–1.9 | $1,200+ |

Custom designs are available for specialized requirements, with bulk orders offering cost efficiencies4.

6. Why Choose CFC Carbon’s C/C Moulds?

As a global leader in carbon composite technology, CFC Carbon guarantees:

-

ISO 9001-Certified Quality: Rigorous testing ensures consistency and reliability4.

-

24/7 Technical Support: From design optimization to post-sale maintenance4.

-

Global Logistics: Fast delivery to 50+ countries, backed by a decade of industry expertise3.

7. Future Trends and Innovations

The demand for C/C moulds is surging due to advancements in additive manufacturing and lightweighting trends. Emerging applications include:

-

3D-Printed Hybrid Moulds: Combining carbon composites with SLA-printed polymers for rapid prototyping12.

-

Oxidation-Resistant Coatings: Extending mould lifespan in aerobic environments above 400°C3.

Conclusion

Hot-pressed C/C composite moulds are redefining industrial manufacturing with unmatched precision, durability, and sustainability. For industries seeking to enhance productivity and reduce lifecycle costs, CFC Carbon’s solutions provide a proven competitive edge.

Explore our full range of C/C moulds:

CFC Carbon Composite Moulds

Contact Us Today!

CFC CARBON CO., LTD

📧 Email: potter@cfccarbon.com | ☎️ +86-18910941489

📍 Address: Yizhuang Economic Development Zone, Beijing 100176, China

related news /articles:

C/C composite hot pressed moulds / molds–manufacturer in China

High-Performance CFCs Molds: Revolutionizing Industrial Manufacturing

Different types of Carbon fiber Composite materials

Applications of 3D carbon carbon composite | C/C composite material