The effects of carbonization rate on some physical and mechanical properties of the present C/C composite have been described in an

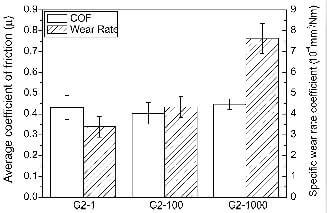

fig.3-effect-of-carbonization-rate-on-friction-coefficient-and-specific-wear-rate-coefficient-of-untreated-composite

earlier study. The results indicated that the randomly oriented chopped carbon fiber/phnolic resin composite processed at a higher carbonization rate had a higher porosity level, more large pores and higher fracture energy than that processed at a lower carbonization rate. After second graphitization the bending properties of composites carbonized at 1 and 1000°C /min were comparable. The

composite carbonized at 1000°C/min had the highest fracture energy. The composite carbonized at 100°C /min showed the worst mechanical performance among three. The variations in average COF and specific wear rate coefficient of the composite prepared with different carbonization rates under the same sliding condition are presented in Fig.3. As can be seen from the figure, the average COF values of all three samples are similar. However, the average wear rate of the sample prepared with a carbonization rate of 1000°C/min is about twice as large as those prepared with lower carbonization rates. These data indicate that wear rate is more sensitive than friction coefficient to carbonization rate, and a higher carbonization rate leads to a larger wear rate. The larger wear rate of G2-1000 than other

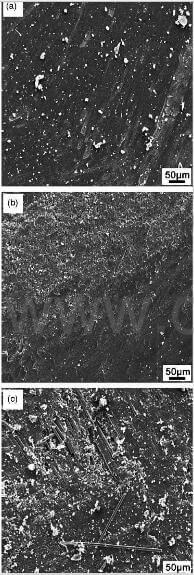

Fig.4-SEM-micrographs-of-worn-surfaces-of-untreated-composite

two samples may be understood from its lower density/higher porosity level, as has been demonstrated in an earlier study. It is generally accepted that C/C composites prepared with higher carbonization rates have lower density and higher porosity values.

Typical worn surfaces of the three composites are demonstrated in Fig.4. As shown in Fig.4a, the worn surface of G2-1 is covered with a smooth film of debris, morphologically similar to the “type Ⅰ” debris as described in an early study. The worn surface of G2-100 is covered with both film type and powdery type debris. The majority of G2-1000 surface is covered with type-Ⅱ debris. Compared to G2-1 and G2-100, more wear debris and more severe structural damage, such as fiber pullout/brakage, are found on the worn surface of G2-1000. According to Shin et al., the debris of hard carbon fiber could promote abrasive wear by braking the soft carbon film on the friction surface. The larger quantity of wear debris and more severe structural damage on G2-1000 surface are believed to be resulted from its above-mentioned higher porosity level.

As mentioned earlier, to improve the tribological performance of G2-1000, the composite was post-treated with an additional process cycle. In so doing, the composite was further impregnated with a liquid precursor optionally doped with a carbonaceous additive, followed by curing, carbonization and graphitization.