Five different carbon carbon composite (C/C) have been prepared and their thermophysical properties studied. These were three needled carbon felts impregnated with pyrocarbons (PyC) of different microstructures, chopped fibers/resin carbon + PyC, and carbon cloth/PyC. The results show that the X-Y direction thermal expansion coefficient (CET) is negative in the range 1-100C with values ranging from -0.29 to -0.85 × 10-6/K. In the range 0-900C, their CTE is also very low, and the CTE vs T curves have almost the same slope. In the same temperature range composites prepared using chopped fibers show the smallest CTE for composites with the same preform architecture. Their expansion is mainly caused by atomic vibration, pore shrinkage and volatilization of water. However, the PyC structure has a large effect on thermal conductivity (TC) with roug laminar PyC giving the highest value and isotropic PyC giving the lowest. All five composites have a high TC, and values in the X-Y direction are much larger than in the Z direction. Heat transmission in these composites is by phonon interaction and is related to the preform and PyC structures.

Because C/C composites have excellent thermal properties of good heat transmission, low CTE and high mechanical strength at high temperature, they have been successfully uses in the manufacture of aviation engine nozzle and thermal assemblies of the firebox as well as brake discs for airplane in the aeronautical, astronauticl, military, and civil fields. In these applications, thermophysical properties of C/C composites are very important, but they have been few reports about them. Preform architecture, microstructures of PyC, density and porosity of composites have a significant effect on the thermophysical performance of C/C composites. Baxter et al. reported that TC of the low density C/C composite increases with increasing temperature from 1000 to 2000C, but that of the high density C/C composites decreases and CTE increases. In this paper, the effect of the preform architectures and the microstructures of the matrix carbon on the thermophysical properties of the C/C composites was investigated. The mechanisms of thermal expansion and heat transmission for the C/C composites are discussed.

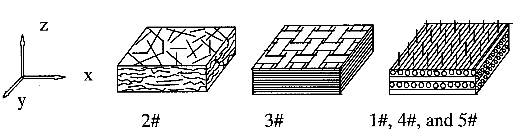

Fig.1-3 kinds of preform archetictures

The PAN based carbon fibers (CF) containing 12K filaments per tow were used as the precursor of the C/C composites. The three kinds of preforms were manufactured according to the following steps: For preforms 1#, 4#, and 5#, CF felts have been laminated (Fig.1), and two successive layers have been oriented at an angle of 90°. Then they were needled progressively till the thickness of preforms, which have been described elsewhere. Preform 2# was prepared by hot pressure of the chopped CF infiltrated using the phenolic resin and following carbonization and graphitization. Plain type HS carbon cloth of 1K PAN based fiber was used to prepare the preform 3# by spreading layers of carbon cloth. Thickness of single layer is 0.15mm. The five composite samples (named as 1#, 2#, 3#, 4#, and 5# respectively) were prepared from the different preforms. The volume fraction of CF in five preforms is all 40%. The porosity of the preforms is 60%. The size of preforms is 400 and 150mm in outer and inner diameter, 15-30 mm in thickness. The reactant and carrier gases are propylene and nitrogen, respectively. After the density of the five composites reached 1.70-1.75 g/cm3, they were treated at 2500C for 2h.

Macroporosity (P) of C/C composites is calculated from the relation

P=1-υf-(ρ-υfρf)/ρp

Whereρis the apparent density of composites, ρf and ρp are the densities of CF and PyC respectively. The densities are measured according to the method reported by. υf Is the volume fraction of CF in the preform.