The ultimate tensile fracture of CFCCs has proven to be significantly influenced by the interfacial bonding between the reinforcing fibers and the matrix. Curtin and co-workers have proposed theories to predict σu of unidirectionally reinforced composites, and these models were shown to be effective for CFCCs and CFRPs. In order to understand the tensile fracture mechanisms of C-C, Curtin’s equations were applied to the present results and the calculation results were compared with the experimental observations. According to Curtin et al., the tensile of brittle matrix composites is primarily controlled by the statistical features of fiber strength and interfacial sliding stress between the fibers and the matrix. Hence, for the calculations of the C-C tensile strength using Curtin’s equations, it was necessary to determine the Weibull parameters, i.e., shape parameter m and scale parameter x0, of the fibers. For this purpose, tensile tests of carbon fiber IM600 were conducted after the heat treatment at 2273K and 2573K, and a part of the results are shown in the companion paper. These fiber strengths might differ from those within the C-C. However, both strengths were considered to coincide approximately in this HTT range, as discussed in the companion paper. In these experiments, m was determined to be 5.8 for the RC- 2273K and 5.3 for the RC-2573K. Since the fibers significantly degraded in the HIP-treated materials, calculations were made for the resin-charred materials. Tensile strengths were predicted using the global and local load shearing models of Curtin et al., and the bundle strength of Coleman, which is ultimate of vanishing interfacial strength.

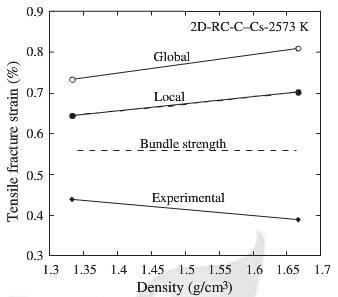

The predicted values using Curtin’s equations were compared with those of the experimental observations in  Fig 16 for 2D-RC-2573K. As this figure shows, the experimentally determined εus were approximately one-half of the predicted values, and the experimental εu increased, but the predicted εu decreased, with increase in the C-C density. These results show that the Curtin models are not appropriate for explaining the tensile fracture of C-C. In their models, the matrix cracking was assumed to be saturated, and the fiber-matrix interface was completely debonded before the ultimate tensile fracture. Thus, the tensile load was assumed to be sustained by unbroken fibers and interfacial sliding friction. C-C generally possess much higher interfacial strength than high performance CFCCs. Hence in the C-C, the fiber-matrix interface might not be completely debonded, even at the ultimate tensile fracture. Similar behavior was observed in CFCCs possessing high interfacial strength; brittle tensile fracture without fiber-matrix debonding was observed in this case. Many authors have assumed that tensile fractures of C-C were initiated by matrix cracks, and that the matrix cracks penetrated into fibers. The present results give partial evidence for this mechanism.

Fig 16 for 2D-RC-2573K. As this figure shows, the experimentally determined εus were approximately one-half of the predicted values, and the experimental εu increased, but the predicted εu decreased, with increase in the C-C density. These results show that the Curtin models are not appropriate for explaining the tensile fracture of C-C. In their models, the matrix cracking was assumed to be saturated, and the fiber-matrix interface was completely debonded before the ultimate tensile fracture. Thus, the tensile load was assumed to be sustained by unbroken fibers and interfacial sliding friction. C-C generally possess much higher interfacial strength than high performance CFCCs. Hence in the C-C, the fiber-matrix interface might not be completely debonded, even at the ultimate tensile fracture. Similar behavior was observed in CFCCs possessing high interfacial strength; brittle tensile fracture without fiber-matrix debonding was observed in this case. Many authors have assumed that tensile fractures of C-C were initiated by matrix cracks, and that the matrix cracks penetrated into fibers. The present results give partial evidence for this mechanism.

The bundle strength of fiber was σb 2.28Gpa, which was obtained using Coleman’s equation, average strength, and m. The discrepancy between Curtin’s predictions and the bundle fracture strains represents the contribution of interfacial sliding stress, and the differences between the bundle εu and the experimental values may demonstrate the effects of stress concentrations caused by matrix cracking. Hence, it can be concluded that the tensile strength of the C-C should be discussed from the viewpoint of the extension of matrix cracking into the fibers. Consequently, the interfacial debonding stress plays a decisive role.

The tensile strengths of C-C changing bulk density, and the tensile fracture mechanisms of the C-C were discussed based on the experimental results. The conclusions obtained were:

- In the low-density region, the tensile strength of the C-C was enhanced with increasing density. This enhancement was caused by an improvement in Young’s modulus of the C-C.

- The ultimate tensile strain of the C-C was improved with a decrease in the interfacial debonding stress.

- The carbon fibers in the C-C were gradually degraded with the repetition of the HIP process.

- The tensile fracture of C-C is suggested to be primarily controlled by the interfacial bonding strength and fiber strength.

- The tensile fracture of the C-C was suggested to be caused by the penetration of matrix cracking into fibers. Thus, the fiber-matrix interfacial debonding stress plays a decisive role in the tensile fracture of C-C.