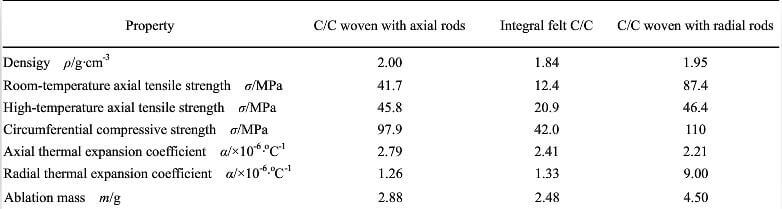

Performance evaluation: A number of tests were carried out to acquire the mechanical and thermal properties properties in order to evaluate the performance of the C/C composites. The ablation test was conducted using a standard SRM platform and the results were compared with the C/C composite reinforced by integral felt and C/C composite woven with radical rods as shown in Table 2. The CTE of the C/C composite woven with axial carbon rods is equivalent to that of the integral felt C/C composite while the mechanical properties of the former are much higher than that of the latter. The ablation mass of the C/C composites woven with axial carbon rods is slightly higher than that of the integral felt C/C composites, but lower than that of the C/C composites woven with radical carbon rods. Room temperature tensile strength of the C/C composites woven with axial rods is lower than that of the C/C composites woven with radical carbon rods while their tensile strengths are almost identical at 2800°C. It can be concluded that the C/C composites woven with axial carbon rods have a good comprehensive performance including mechanical, ablation and thermal properties, which are expected to meet the requirement of high pressure and large flow working condition for the high performance SRMs.

Table.2-Properties of three kinds of CC composites

Application of the C/C composite throat insert woven with axial carbon rods:

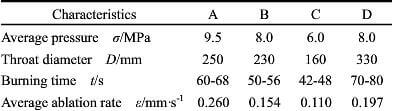

Four types of SRMs were used to evaluate the anti-erosion ability of the C/C composites woven with axial carbon

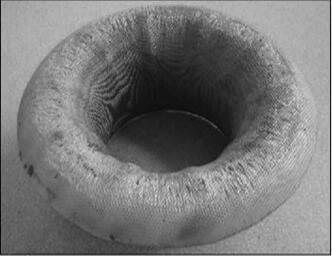

Fig.7-image-of-the-CC-composite-throat-insert-before-test

rods. Photographs of the C/C composite nozzle throat before and after SRM’s firing test are shown in Fig.7 and Fig.8, respectively. It can be seen that the throat insert after ablative test keeps its integrity and there is no crack inside and outside the throat insert. The ablation surface is smooth and their ablation rates are shown in table 3.

Table.3-working conditions of SRMs and ablation rates of the CC composites

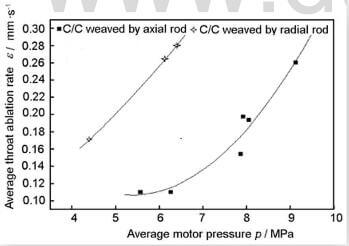

Fig.9 shows the ablation properties of the C/C composites throat insert woven with axial carbon rods under different SRM combustion pressures. It is clearly shown that the ablation resistance of the C/C throat insert woven with axial carbon rods is

Fig.8-image of the CC composite throat insert after test

higher than that of the C/C throat insert woven with radical carbon rods. Under test condition of 6.0 Mpa-9.5 Mpa, the C/C throat insert woven with axial carbon rods exhibited excellent mechanical, ablation and thermal properties. The ablation rate at the test pressure of 9.5 Mpa is 0.260 mm/s, which is 60% lower than that of the C/C throat insert woven with radical carbon rods at the same conditions.

A new kind of preform was woven with axial carbon rods and its fibers in different directions intentionally distributed to increase the fraction of radical fibers. An optimized process was developed to prepare the C/C composite with high quality that meet the requirement of the application in high performance SEMs.

The C/C composites prepared from the new preforms have good mechanical properties and lower ablation rates that the C/C composites woven with radical carbon rods. The density of the C/C composites could be up to 2.0

Fig.9-SRM pressure dependence of ablation rate for various CC composites

g/cm3 and their tensile strength at 2800°C could be up to 40 Mpa while their average axial CTE was only 2.79*10-6°/C. So far, the C/C composites throat inserts woven with axial rods have passed the test for four types of SRMs.