Densification process:

As-prepared preforms were firstly densified by means of PIC, and then with a multistep process of HPIC and HTT. The HPIC and HTT process had been repeated several times as showns in Fig.2. to obtain the C/C composites with a high density. After 4-5 cycles of HIPC and HTT, the density of this new kind of C/C composites could be up to 2.0 g/cm3.

Microstructure characterization:

Microstructures of carbon matrix were investigated by optical microscopy with a plarized light. The microscopic morphologies of the C/C composites, fiber/matrix interfaces and defects were analyzed by field emission scanning electron microscopy (Zeiss Supre 55)

Mechanical measurements:

Mechanical properties of the C/C composites under room temperature were measured with a universal testing machine (INSTRON 4505). The dimension of specimens for tensile test was D15*73mm, and that for compressive test was 20-20-20mm. The high temperature mechanical properties of the C/C composites were tested at 2800°C using an ultrahigh temperature mechanical testing system. The dimension for tensile test at the ultrahigh temperature was D18-130mm with an effective section of D8-40mm.

Thermal measurements:

The coefficients of thermal expansion (CTE) were measured using a vertical ultrahigh temperature thermal expansion instrument. The testing range for thermal expansion was 0.5*10-6/°C-300*10-6/°C, and the specimen dimension was D6*25mm.

Albation measuremens:

The ablation test was conducted on a standard SRM platform using hydroxyl-terminated polybutadiene as a propellant and a working time of 20s. The mass difference of the C/C composites before and after the ablation test was defined as the ablation mass to describe the ablation esistance of the quadrate C/C composites throat inserts.

Results and discussion:

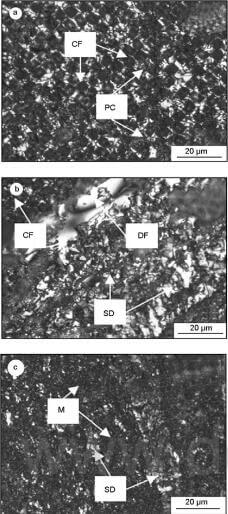

Microstructure of as-prepared C/C composites reinforced by preform woven with axial rods was shown in Fig.3.

Fig.3-polarized-light-micrographs-of-the-CC-composites

As can be seen from Fig.3a, the carbon fibers in the axial fiber bundles hardly exhibit optical activity. While the white pitch based carbon was located in the spaces between carbon fibers without any residual pores left, which indicated that the pitch could be impregnated into the preform adequately and retained under the high pressure carbonization porcess. Due to the limited spaces, pitch based carbon in the carbon fiber bundles is of mosaics structure, not of domains structure. As annular optically active belt between axial fiber and matrix was found in Fig.3b, where the polarized light structure of pitch based carbon is mainly of small domains, and a small amount of domain and flow domain structures existed near the fiber bundle. Testures inside the matrix exhibited a low optical activity, and mainly featured with mosaics and domains structures. During the densification, PIC and HPIC were used successively, which resulted in the formation of carbon matrix with different microstructures in the same preform, even in the same microdomain. Fig.3c diaplayed that mosaics structures and domains structures were coexistent in the same microdomain. From the polarized light micrographs of the C/C composites shown above, it could be found that dense structures and suitable interfaces can be obtained through optimizing the densification process.