The isothermal oxidation of a 2D C/C composite was investigated by thermogravimetric analysis in the temperature range of 745-900°C and SEM observation. The model-free, model-fitting and reduced-time plot methods were applied to oxidation kinetic analysis. SEM

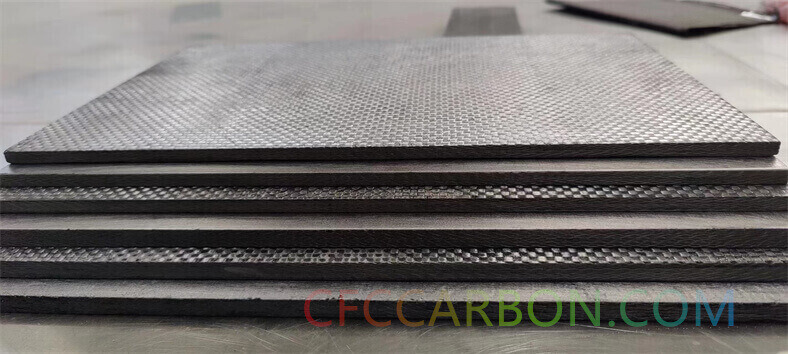

carbon fiber composite plates sheets U L profiles-2D material manufactuer china (5)

investigation shows that oxidation starts from the fiber/matrix interfaces, and matrix carbon is oxidized much more repidly than the carbon fibers. According to the model-free curve, the oxidation temperatures are divided into two ranges: lower temperatures and higher temperatures. The apparent activation energy and oxidation controlling mechanisms in different temperature ranges are obtained. Furthermore, the trend of the oxidation rate with weight loss or temperature ranges is discussed by the combination of microstructure and mechanisms of oxidation of 2D C/C composite.

Carbon-carbon composite are widely used in aerospace industry, owing to the rare combination of physicochemical properties such as light weight, good friction and wear properties, high toughness and thermal stabilit. In an inert atmosphere or vacuum, C/C composites can retain the superior properties to very high temperatures of approximately 3000°C. Nevertheless, like other carbon materials, when exposed to an air at high temperatures, C/C composites will be oxidized at temperatures as low as 500°C. The properties of C/C composites are degraded by oxidation, expecially mechanical properties. Thus, a great deal studies on oxidation behavior of C/C composites have been carried out in order to make clear oxidation mechanisms and broaden their applications as high temperatures structural material in air environment.

2D carbon fiber composite plate sheet-s

Most investigations of oxidation behavior of C/C composites are focused on isothermal oxidation kenetics or microstructural characteristics of attack. Dacis et al. proposed that the oxidation process in there stages based on the shape of the thermogravimetric curve. Luo et al. suggested the oxidation rate is controlled by the chemical reaction of carbon and oxygen at about 600-700°C and simultaneously by the chemical reaction and gaseous diffusion between 700 and 800°C. Oxidation is typically along the fiber axis at the fiber/matrix interfaces.

There is a common approach on isothermal oxidation kinetics of C/C composites in the aforementioned papers. Firstly, thermogravimetric curve is divided into some parts by means of the linear discrimination method. Secondly, the kinetic analysis on each part is implemented. In the linear part, the kinetic equation follows the expression: △mt/mo=kt, where mo is the initial weight of the specimen, and k is the oxidation rate constant; in the non-linear part, the kinetic equation follows the expression: △mt/mo=1-e±kt. The kinetic equation of oxidation of C/C composites has been simplified. Moreover, the microstructure of initial oxidation was not investigated in detail. Crocker and MeEnaney found that the initial oxidation had a dramatic effect on mechanical properties of C/C composites. So it is very necessary to understand the microstructure of initial oxidation.

This work investigated the oxidation behavior of a two-dimensionally reinforced carbon/carbon composite in flowing air under isothermal conditions. Compared with former studies are two new improvements in this study. Firstly, in situ SEM observation was implemented for the initial oxidation. Secondly, the model-free, model-fitting and reduced-time plot methods were introduced for kinetic analysis.

related news /articles:

Oxidation kinetics and mechanisms of a 2D C/C composite (3)

Oxidation kinetics and mechanisms of a 2D C/C composite (5)

Oxidation kinetics and mechanisms of a 2D C/C composite (2)

Experimental Investigation of Isothermal Oxidation Kinetics in Carbon-Carbon Composites