Nuclear graphite, is a kind of graphite material used for the nuclear industry. Graphite for thermal neutron reactors, also hopefully for the fusion reactor, in the thermal neutron reactor can be used as a fuel zone neutron moderator, the fuel zone around the reflective layer of material, and the core of the internal structure of the material.

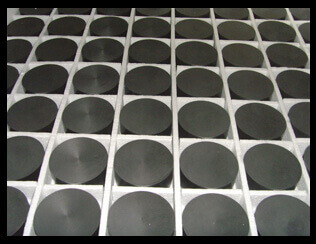

high purity isostatic graphite rods blocks rounds blocks material manufacturer factory China (4)

Brief History

In 1942, Enrico Fermi led his team, using natural uranium and its oxides as a raw material, with graphite as moderator, to achieve the world’s first self-sustaining chain reaction, is the world’s first one nuclear reactor, known as the “CP-1” reactor. At that time, 385t graphite was used as moderating material, among which the most used was AGOT graphite. Since then, the graphite used as an important nuclear material and emphasis by most countries. and did much reach and study on its manufacturing process, physical properties, radiation effects.

Graphite is used for thermal neutron reactors, also hopefully for the fusion reactor, in the thermal neutron reactor can be used as a fuel zone neutron moderator, the fuel zone around the reflective layer of material, and the core of the internal structure of the material.

3 advantages and disadvantages

The advantages and disadvantages of graphite as a reactor material are as follows:

(1) graphite has a high cross-section and a very low thermal neutron absorption cross section, the higher cross-section for the slow neutron scattering, low absorption cross-section to prevent neutron absorption, the nuclear reactor can use a small amount of fuel to reach the critical Or normal operation. In this case,

(2) graphite is a high-temperature materials, its three-phase point, 15MPa when 4024 ℃, it can not be melted, casting, forging and other hot processing methods can only be manufactured using similar methods of powder metallurgy. It does not like the metal, the strength decreases with temperature raising, but a slight increase. Application under 2000 ℃, will not be a problem.

(3) graphite has good thermal conductivity, in the heap can effectively reduce the temperature gradient, will not produce too much thermal stress.

(4) Graphite chemical properties are very stable. In addition to high temperature oxidation, water vapor, it can be resistanct to acid, alkali, salt corrosion, which can be used for molten salt reactor and uranium bismuth nuclear reactor core components.

high purity isostatic graphite rods blocks rounds blocks material manufacturer factory China (7)

(5) excellent anti-radiation properties of graphite, long service in the reactor 30 to 40 years.

(6) graphite machinability, and can be processed into various shapes of components.

(7) graphite is rich in raw materials, cheap, easy to produce high purity, high strength, different density requirements of various nuclear graphite, but graphite also has shortcomings, it is anisotropic crystal structure, layered distribution, atoms densely in a , b crystal plane, the closest distance of the same layer of atoms 0.141nm, covalent bond with each other, with strong binding; layer distance of 0.335nm, interlayer adhesion Van der Waals force, weaker binding. This anisotropy in the graphite of the physical, intensity, radiation and other behavior will be strongly demonstrated.

We are manufacturer of graphite material and products in china, with stable and reliable quality. Our material: Mouled graphite, isostaitc graphite, vibration graphite, extruded graphite, mechanical graphite and carbon brush materials. Products: machined graphite parts, graphite pipes, mechanical seal and bearing, carbon brushes and graphite bipolar plate..