Reflection light microscopy: Polarized reflection light microscopy was carried out using a Leica DM LM optical microscope. In order to characterize the optical anisotropy, the extinction angle Ae was measured.

Transmission and scanning electron microscopy: TEM was carried out using a LEO EM 912 Omega transmission electron microscope at an electron energy of 120 keV. Zero-loss filtered selected area electron diffraction patterns were acquired to quantify the degree of texture by the orientation angle.

Freshly fractured surfaces were examined by scanning electron microscopy (SEM) in a LEO 1530 microscope without evaporating conductive layers prior to investigation. Details of SEM observations are given elsewhere.

Atomic force microscopy: The AFM investigations were performed with a commercial AFM at ambient conditions. Commercially available V-shaped silicon cantilevers with force constants between 0.2 and 0.4 N/m were used. The images were taken in the contact mode of the AFM in the repulsive force regime with a total normal force in the range of 0.4-1.0*10-7 N including capillary forces.

Laser scanning confocal microscopy: Laser scanning confocal microscopy was performed with a Leica TCS SP2/*1. Polarized light with a wavelength of 458 nm from an Ar+ ion laser was used for illumination. The focus of the laser beam was scanned two-dimensionally parallel to the plane of the sample surface and the sample was moved in the direction perpendicular to the sample surface to acquire images. Topography images were generated by using the z coordinate with the highest measured intensity for each xy-position. Maximum intensity images were generated by plotting the highest measured intensity for each xy-position.

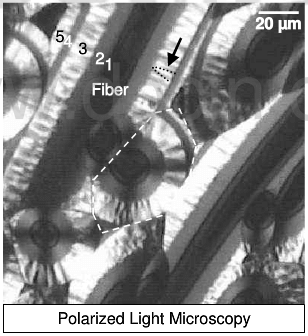

Results: Figure 1 shows a representative PLM image of a polished section of the infiltrated carbon fiber felt. The  carbon fibers are randomly oriented within the C/C composite. The deposited matrix material replicates the cylindrical shape of the fibers. A structural unit which in the following will be called a “cell” is defined as the volume of one fiber plus the matrix material deposited on this fiber. Therefore, the infiltrated felt can be considered to be composed of a number of cells corresponding to the number of fibers in the carbon fiber preform. The matrix in each cell consists of up to five concentric layers exhibiting different optical anisotropy. Based on the measurements of the extinction angle Ae the texture degrees of the layers are: low-, medium- and high-textured.

carbon fibers are randomly oriented within the C/C composite. The deposited matrix material replicates the cylindrical shape of the fibers. A structural unit which in the following will be called a “cell” is defined as the volume of one fiber plus the matrix material deposited on this fiber. Therefore, the infiltrated felt can be considered to be composed of a number of cells corresponding to the number of fibers in the carbon fiber preform. The matrix in each cell consists of up to five concentric layers exhibiting different optical anisotropy. Based on the measurements of the extinction angle Ae the texture degrees of the layers are: low-, medium- and high-textured.