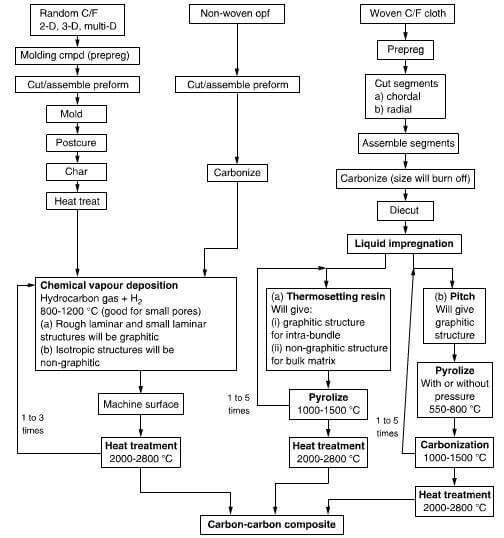

A schematic layout of some methods which can be used to fabricate carbon-carbon composites from different reinforcement materials is shown in Fig 14.4. Material processed at 1100C by the thermal pyrolysis of a carbon bearing vapor has an isotropic nature and is termed pyrolytic carbon, whereas material processed in the range 1000-1700C is of a more intermediate nature, becoming increasingly graphitic with rise in temperature, whilst material processed at 1700-2300C, deposited from a hydrocarbon gas, gives an increased graphitic nature and is loosely termed pyrolytic graphite.

schematic layout of typical methods used to fabricate carbon-carbon composite from different reinforcement materials.

After densification of the preform, the matrix pores become blocked, preventing any more carbon precursor from penetrating the fiber array and it is believed that at this stage that the composite can be cooled quickly, so that the matrix cracks due to a thermal mismatch, allowing the densification process to be continued by filling the cracks so formed. This process can be repeated some 4-6 times.

Use of gas phase impregnation and densification:

Chemical vapor deposition involves heating a fiber preform in gaseous environment to deposit the mtrix, present in the gaseous phase, on to the fiber. The term chemical vapor infiltration is used to describe CVD densification occurring within the fiber preform at distinct from a simple surface deposition technique.

Although CH4 requires a temperature above 550C to initiate carbon deposition, it is widely available and has excellent diffusion properties and is hence, widely used in CVD process. Diffusion can be increased further by dilution with H2, He, N2 or Ar to increase the mean free path of the CH4.

It is essential to ensure the correct balance between diffusion and surface reaction kinetics and a high rate of deposition will tend to block the pores and not fill them. Inevitably, this blocking will occur during the process and it becomes necessary to machine the surface to re-open the pores for subsequent filling. Consequently, to achieve successful densification of the composite, the CVD process must have protracted processing times.