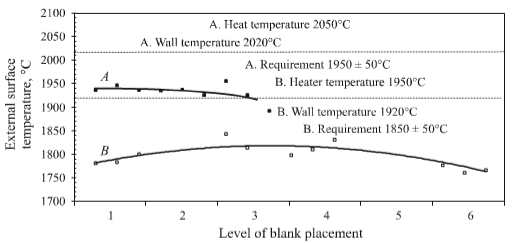

The required value of treatment temperature for a charge may only be provided in some single area for product location. In rest of the areas the level of temperature in relation to internal heat flows is distorted and does not correspond to the requirements for the production process. The amount of non-conformity may reach 70-80°C, which is markedly greater than the error of optical measurements. The first level for location of blanks as noted above is raised by the graphite stand by 600 mm above the hearth of the workspace. Therefore the minimum temperature for a charge is established for the upper section of blanks. Location of a heat screen at the upper level may apparently lead to considerable equalizing of charge temperature. Temperatures established at the inner surfaces of blanks are not provided in Fig.2. They are 40-50 degrees less than the temperature of the outer surfaces. Blanks being treated, participating in redistribution of heat fluxes, become re-emitters within a furnace with establishment of a steady-state direction for thermal energy flow. It follows from data in Figs 1 and 2 that in large electric vacuum furnaces the actual treatment temperature achieved for blank is material is with an error up to 100°C, which is greater than the error of optical measurements.

fig.2-permissible temperature limit at points of placing control specimens at outer surface

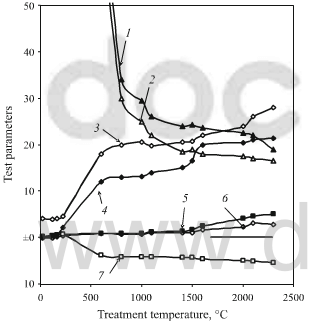

In order to study the permissibility of the HTT production operations noted, a study was made of physicomechanical and thermophysical properties of treated blank materials. Results are shown in fig.3 for testing physical, electro-physical, and deformation properties of C/C composite material during carbon-reinforced plastic hardening, carbonization and HTT. The reinforceing filler carbon, i.e., carbon fiber, has a higher original high-temperature production treatment, and therefore it is stable over the whole test temperature range. Features presented that occur in material in all stages of the production process of physicomechinical and structural processes reflect the rate, depth, and completion of conversion within polymer and then in a carbon matrix.

fig.3-change in phsical, electrophsical properties of carbon material and their deformation

It is possible to separate three regions from the data in fig.3 in the HTT temperature range. With a temperature of 800 to 1273°C shrinkage and weight loss are stabilized, and there is formation of a carbon turbostratic two-dimensional crystal structure, and a change-over is observed towards with respect to the level of electrical conductivity, typical for carbon material. The specific electrical conductivity for carbon materials, as is well known, depends on their porosity and degree of perfection of the crystal and electron submolecular structure of coke.

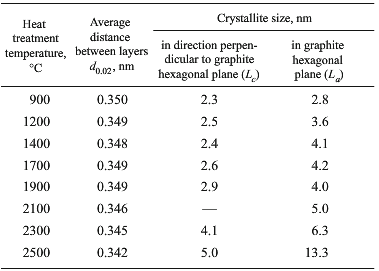

Results of studying the perfection of material crystal structure of high-modulus fibers based on polyacrylonitrile with a carbon matrix of phenol formaldehyde resin coke in the production and treatment temperature range from 900 to 2500°C are provided in Table 1. The 3D crystallization of the test CCCM commences not sooner than reaching a temperature in the range 2100-2300°C. The results obtained due to the fact that both components of the carbon composite of this production stage are related to “non-graphitized” components. Therefore a reduction in specific electrical conductivity of a carbon composite may be connected with transformation of the pore structure, compaction of contacts at the interfaces of a carbon matrix-carbon filler, and carbon matrix-carbon matrix.

table.1-change in x-ray structural properties of C-C material of high modulus treads