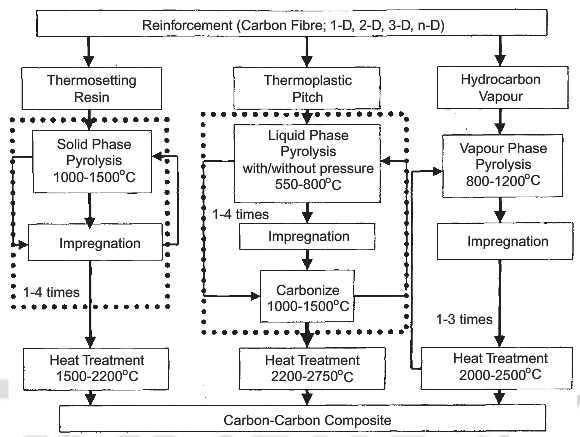

Like carbon, carbon-carbon composites can also be manufactured by using different techniques such as all solid pyrolysis using thermosetting resins, or pitch route using liquid infiltration carbonization route or CVD route. Fabrication method of C/C composites involves fabrication of a 3D or MD porous carbon fiber preforms having the desired shape or a porous carbon-carbon skeleton with carbon fibers and a carbonaceous matrix followed by their densification. The densification can be achieved through vapour phase infiltration (CVI) wherein the hydrocarbon gases such as methane, propane etc. infiltrate into porous fibrous structure heated to a temperature of 1000-1400C and are made to crack therein. Commercially, isothermally heated stack of components are impregnated

processing of carbon-carbon composites

simultaneously in a large-size furnace. Principally, the gases should infiltrate into the pores and interfilamentary spaces and then crack. But these gases have a tendency to crack at the outer surface itself which blocks the passeges and causes closed pores. In order to have dense composites, the surfaces are ground and the components are reinfiltrated. CVD is a very slow process and it takes months together to get dense carbon-carbon composites. Porous structures can also be impregnated with liquid phase pitch/phenolic resin followed by carbonization and high temperature heat treatment. Pyrolysis of the pitch/resin matrix can be done under normal pressure or under high pressure (HIP).

Depending on the densification approach, two or more densification cycles are required to get the desired density, the number of impregnation cycles being fewer when HIP processes is used. A new approach of intermediate graphitization has been evolved in which the composites after certin impregnation/normal pressure carbonization cycles are heat-treated to high temperature and then reimpregnated. This intermediate high temperature heat treatment opens up the pores for further infiltration. Often a combination of processing routes is used for densification processes. These comprise fabrication of host composites using a pitch or resin route followed by densification and pre sealing by CVD.