High density C/C composite normally means material with density higher than 1.8g/cm3. CFCCARBON LTD can produce C/C composite

3D carbon fiber composite material manufacturer factory (4)

with density upto 1.90g/cm3 or 1.95g/cm3. This density is the best for C/C composite material already. its almost the real density for

graphite, which is only 2.2g/cm3.

There are different names of the material: CFC, Carbon composite, C/C, carbon fiber composite, carbon carbon composite, carbon reinforced carbon, carbon fiber reinforced carbon, carbon carbon… but its the same material. its different from carbon fiber products. because the C/C composite material can withstand high temperature, but the carbon fiber products can not.

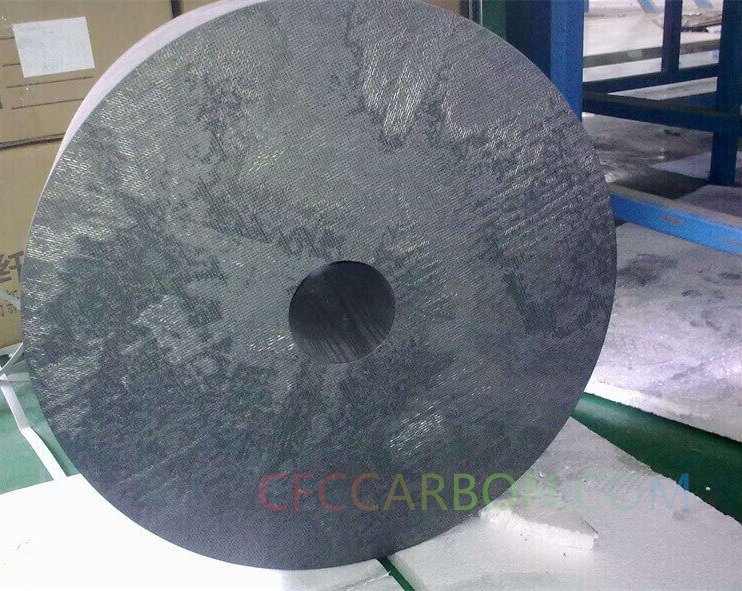

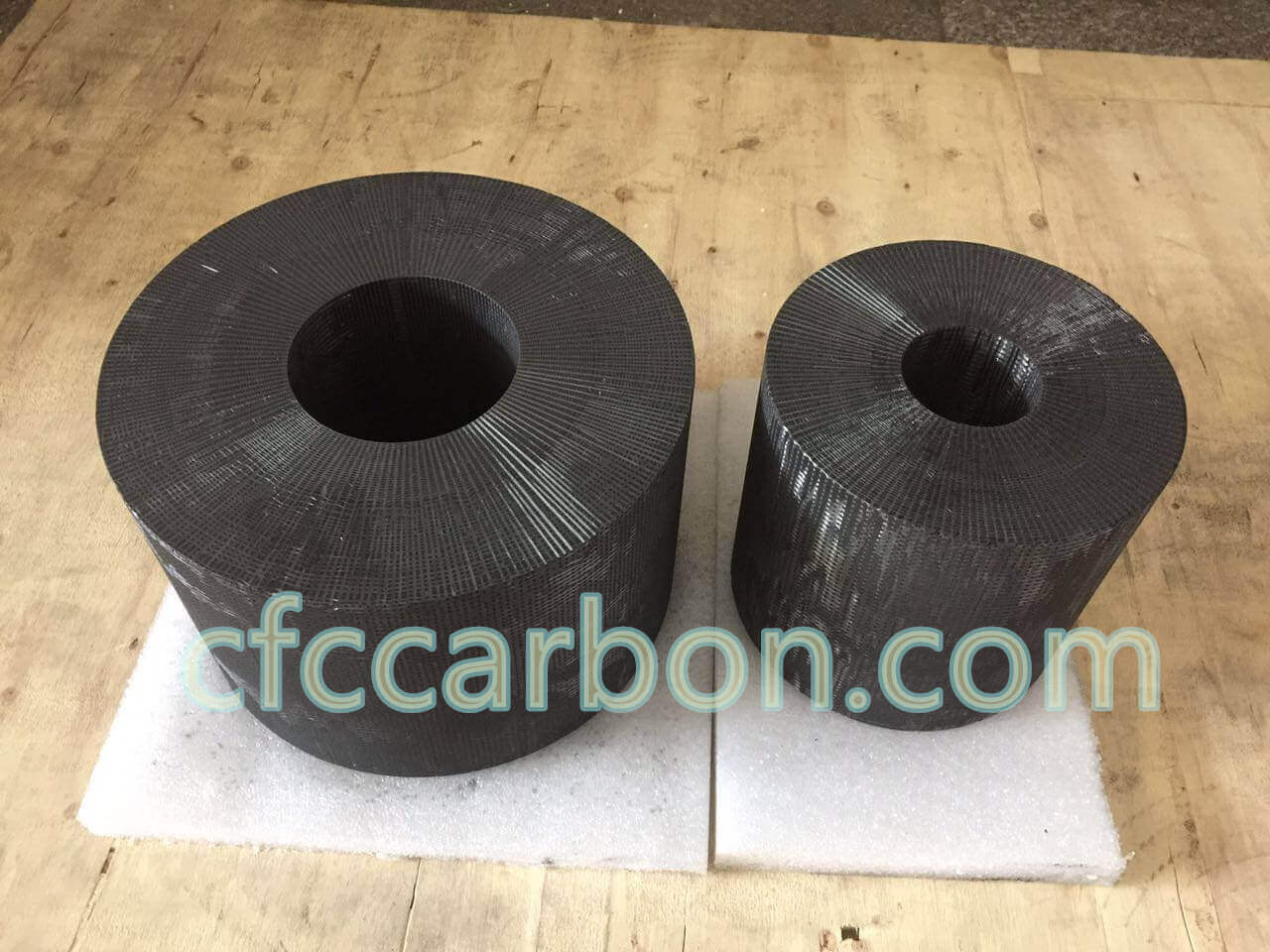

Our company can supply high density carbon composite with stable and reliable quality. We can produce all kinds of High density CFC. with upto 1.9g/cm3 density. CVI , CVD or Pitch coke based processing. temperature: >2000C. Density: 3D, 4D upto 1.9g/cm3. as per customers’ requests.

We can also produce pitch coke based C/C composite, with density higher then 1.9g/cm3. Hoop structure.

Please see the data sheet of highe density C/C composite, with 3D structure, CVD/CVI process:

| Specification | Requirements | Test results |

| Bulk density | 1.85 g/cm3 min | A1: 1.87g/cm3 |

| 1.85 g/cm3 min | A2: 1.87 g/cm3 | |

| 1.85 g/cm3 min | B1: 1.88 g/cm3 | |

| 1.85 g/cm3 min | B2: 1.87 g/cm3 | |

| Make of fibers | Four dimensions (4D) | Four dimensions (4D) |

| Tensile strength | X-Y: ≥130MpaZ:: ≥70Mpa | X-Y: 165MpaZ:: 78Mpa |

| Tensile Modulus | X-Y: ≥50GpaZ: ≥30Gpa | X-Y: 56GpaZ: 36Gpa |

| Flexural strength | X-Y: ≥120Mpa | X-Y: 139Mpa |

| Compressive strength | X-Y: ≥160MpaZ:: ≥220Mpa | X-Y: 164MpaZ:: 273Mpa |

| Thermal Conductivity | X-Y: ≥40 W/mkZ: ≥20W/mk 900°C | X-Y: 49 W/mkZ: 25W/mk 900°C |

| C.T.E (1000°C) | X-Y:0.5-1 ×10-6/KZ: 1-1.5 ×10-6/K | X-Y:0.62×10-6/KZ: 1.23×10-6/K |

| Porosity | 3-5% | 4.2% |

| Cp at RT-590°C | Report | X-Y:1.553 103J/(Kg.K)Z:1.635 103J/(Kg.K) |

| X-ray Inspection | No significant defects | No significant defects |

High density CC composite has the following properties:

(1) Physical properties: After high temperature treatment, the carbon composite has higher carbon content, >99%, the density is low, the

3D 4D 5D Hoops, Loop, weaving, stucture, drawing, carbon fiber, carbon, composite, CFC, CC, manufacturer, China, (1)

mechanical properties are good. Due to good characteristic of high melting point of carbon, high temperature resistance, corrosion resistance and thermal shock performance, the carbon composite is resistant to acid, alkali and salt.This is one order for our customer. and we have other customers require density of 1.90g/cm3 min.

High density C/C composite has advantages of long lasting lifetime, low competitive costs, light weight…

(2) Mechanical properties: carbon composite has good mechanical properties of the strength and elastic modulus, good wear and tear resistance.

(3) high-temperature stability: The room temperature strength of carbon composite can keep up to 2500 ℃, is not sensitive to the thermal stress, and the ablation resistance performance is good.

(4) Comprehensive performance evaluation: carbon composite has good strength and elastic modulus at room temperature; less production processes of carbon composite material can save materials and manufacturing costs, and its more safety and reliability.

Special Properties of carbon carbon composite: High Acid-resisting and alkali-resisting properties; Low density compared to metals; High temperature, cold-resistant, tensile strength is 7-9times than Steel; very good thermal shock resistance…

Note: We can do X-RAY tests and other tests.

We can produce with all shapes of High density CFC, as per customers’ special request.

Our Products were sold throughout the country and exported to Europe, America, Southeast Asia and other countries and regions which enjoy a high reputation all over the world. We hope to establish a good business relationship with you; we will serve you with the best quality, best delivery time and best solutions.

related news /articles:

Properties of high density carbon carbon composite | C/C composite

3D Carbon fiber composite | CFC material manufacturer in China

4D Carbon fiber composite | CFC material manufacturer in China