1. Innovative Material Engineering in Vacuum Technology

Modern industrial applications demand vacuum pump components that combine durability with precision engineering. As a leading manufacturer of specialized carbon-graphite solutions, CFCCarbon delivers high-performance graphite vanes engineered for rotary vane vacuum pumps across aerospace, semiconductor manufacturing, and chemical processing industries. Our vanes leverage proprietary carbon fiber composites and electrographite formulations to outperform conventional materials in extreme operating conditions.

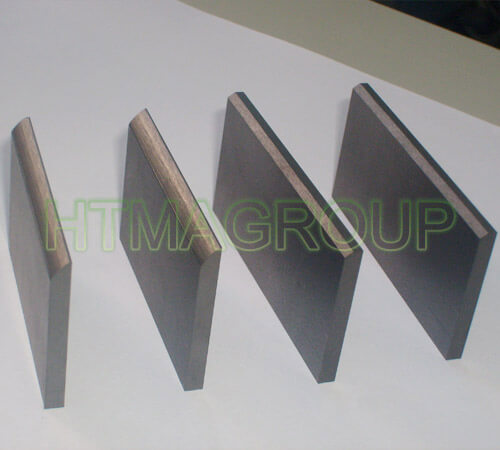

graphite vane manufacturer in china

2. Technical Advantages of Graphite Vanes

Graphite vanes excel in critical performance metrics:

-

High-Temperature Stability: Operate continuously at 400°C+ without deformation, ideal for thermal-intensive processes like metal smelting.

-

Corrosion Resistance: Withstand aggressive chemicals including hydrogen fluoride and alkaline solutions, extending maintenance cycles in chemical plants.

-

Self-Lubricating Properties: Reduce friction by 60% compared to metal alternatives, minimizing energy consumption in continuous operations.

-

Lightweight Design: 80% lighter than copper-based components, enhancing pump efficiency and portability.

3. Precision Manufacturing Process

Our ISO-certified production facility employs advanced techniques:

-

Material Synthesis: Custom-blended graphite composites optimized for specific pump models like Busch R5 and SECO SV series.

-

CNC Machining: Achieve ±0.005mm dimensional accuracy for seamless rotor integration.

-

Surface Treatment: Laser-engraved batch tracking ensures anti-counterfeiting and full traceability.

mechanical carbon vane

4. Industry-Specific Applications

-

Semiconductor Manufacturing: Ultra-clean graphite vanes prevent particulate contamination in wafer fabrication pumps.

-

Pharmaceutical Processing: FDA-compliant materials meet GMP standards for sterile environments.

-

Renewable Energy: Enhanced durability supports hydrogen fuel cell compressors and solar panel production systems.

5. Quality Assurance & Compliance

Every graphite vane undergoes:

-

3-stage stress testing under simulated operational loads

-

Leakage rate verification (<1×10⁻⁹ mbar·l/s)

-

Certification to ISO 9001:2025 and ASME BPVC standards

6. Sustainability Focus

CFCCarbon’s graphite vanes contribute to eco-efficient operations:

-

300% longer lifespan reduces replacement frequency vs. traditional vanes.

-

Recyclable material composition aligns with circular economy initiatives.

7. Customization Capabilities

Tailored solutions for niche requirements:

-

Non-standard dimensions (up to 500mm length)

-

Hybrid designs incorporating glass fiber reinforcement

-

Rapid prototyping with 15-day lead time

8. Global Support Network

With technical centers in 12 countries, we provide:

-

On-site vane replacement by certified engineers

-

24/7 emergency response for critical system failures

-

Interactive maintenance tutorials for SECO SV 1000-series pumps

9. Industry Recognition

Recent milestones:

-

2025 Material Innovation Award (European Vacuum Technology Association)

-

Strategic partnership with Busch Vacuum Solutions for next-gen pump development

related news /articles:

Carbon vane, vacuum pump carbon vane manufacturer in china

Electrical and mechanical applications of molded graphite

Maintenance of Carbon Brush in Operation and Replacement