Introduction to Flexible Graphite Paper

Flexible graphite paper, a high-performance material derived from natural flake graphite, has emerged as a cornerstone of modern industrial sealing and thermal management solutions. Defined as a compressible, sheet-like material composed of expanded graphite particles, it combines the intrinsic properties of graphite—such as thermal conductivity, chemical inertness, and temperature resistance—with enhanced

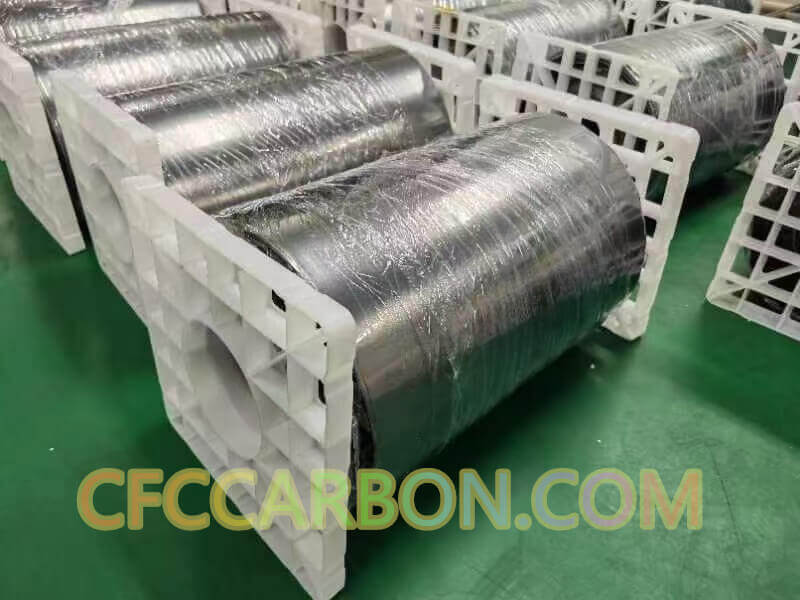

natural flake graphite foil sheet plate (3)

flexibility and durability. Classified into standard, reinforced, and ultra-thin variants, this material is engineered to meet diverse industrial demands. Its key performance attributes include exceptional thermal stability (operating range: -200°C to 3,000°C), corrosion resistance, self-lubrication, and impermeability to gases or liquids. As industries prioritize energy efficiency and miniaturization, flexible graphite paper is evolving toward ultra-thin formats (<0.1mm thickness) and multifunctional composites integrated with metals or polymers, unlocking applications in cutting-edge sectors like aerospace and consumer electronics.

Manufacturing Process: Precision Meets Innovation

The production of flexible graphite paper begins with high-purity natural flake graphite, meticulously processed to retain its crystalline structure. The proprietary manufacturing workflow involves four critical stages:

-

Chemical Intercalation: Raw graphite is treated with acids (e.g., sulfuric or nitric acid) to create interlayer compounds, enabling expansion.

-

High-Temperature Expansion: Rapid heating to 800–1,200°C triggers a 200–400x volumetric expansion, forming “worm-like” exfoliated graphite with a porous structure.

-

Rolling & Calendering: The expanded graphite is compressed into sheets using multi-stage rollers, achieving uniform density (1.0–1.3 g/cm³) and customizable thickness.

-

Post-Treatment: Optional steps include resin impregnation for reinforcement or metal foil lamination for conductivity enhancement.

This process, pioneered by industry leaders like CFCCarbon (www.cfccarbon.com), ensures defect-free layers while preserving graphite’s

natural flake graphite foil sheet plate (2)

anisotropic thermal and electrical properties. Advanced quality control systems monitor parameters like tensile strength (4–15 MPa) and compressibility (>40%), guaranteeing consistency for mission-critical applications.

Performance Characteristics: Engineering Excellence

Flexible graphite paper outperforms traditional sealing materials through a unique combination of properties:

-

Thermal Resilience: Maintains structural integrity under extreme thermal cycling, ideal for nuclear reactors and jet engines.

-

Chemical Inertness: Resists acids, alkalis, and organic solvents, as demonstrated in chemical processing equipment.

-

Gas Tightness: Achieves leak rates <1×10⁻⁶ mbar·L/s in vacuum systems.

-

Radiation Resistance: Stable in environments with neutron or gamma radiation exposure.

-

Conformal Adaptability: Compresses to fill microsurface irregularities, ensuring hermetic seals.

These attributes position it as a superior alternative to asbestos, PTFE, and rubber-based gaskets, particularly in harsh operating conditions.

Industrial Sealing Solutions: Reliability Under Pressure

Over 60% of flexible graphite paper is consumed by the sealing industry. Its primary applications include:

-

Static Seals: Gaskets for pipeline flanges, heat exchangers, and pressure vessels in oil refineries.

-

Dynamic Seals: Packing rings for pump shafts and valve stems in chemical plants, with service lives 3–5x longer than PTFE alternatives.

-

Fire Safety: Intumescent seals in fire-rated doors expand under heat, blocking smoke propagation.

Case studies from CFCCarbon reveal that their MX900 series graphite gaskets reduced downtime by 30% in a Middle Eastern LNG facility operating at 500°C and 150 bar.

Thermal Management: Powering the Electronics Revolution

The rise of 5G and high-density electronics has driven demand for ultra-thin graphite sheets (50–300µm). CFCCarbon’s NanoTherm® line exemplifies this trend:

-

Mobile Devices: 0.05mm sheets dissipate heat from smartphone processors, reducing surface temperatures by 8–12°C.

-

EV Batteries: Intercell thermal interface materials prevent thermal runaway in lithium-ion packs.

-

Data Centers: Graphite-based heat spreaders cool AI server chips with 10x higher conductivity than aluminum.

This sector is projected to grow at 14% CAGR through 2030, fueled by IoT and autonomous vehicle adoption.

Emerging Frontiers: From Aerospace to Hydrogen Economy

Innovators are pushing boundaries with hybrid materials:

-

Fuel Cells: Metal-graphite bipolar plates enable compact PEM fuel cell stacks.

-

Space Systems: Radiation-shielded composites protect satellite electronics.

-

Additive Manufacturing: 3D-printed graphite molds withstand 2,800°C casting temperatures.

CFCCarbon’s recent partnership with a European hydrogen electrolyzer manufacturer highlights graphite paper’s role in green energy—its conductive seals improved electrolysis efficiency by 5.2% while resisting high-pressure hydrogen embrittlement.

Conclusion

As industries confront increasingly complex operational challenges, flexible graphite paper stands at the intersection of material innovation and practical engineering. From ensuring safety in nuclear facilities to enabling slimmer smartphone designs, its versatility continues to redefine industrial possibilities. With R&D focusing on nano-enhanced grades and sustainable production methods, this “wonder material” is poised to underpin tomorrow’s technological leaps. Explore CFCCarbon’s full product portfolio and technical specifications at www.cfccarbon.com.

related news /articles:

Properties and applications of flexible graphite | graphite paper

carbon fiber reinforcement for carbon-carbon composite material.-(1)

Phosphate Aluminum Graphite Material: M120G, a High-Performance Mechanical Seal Graphite