The classical method for fabricating carbon materials involves combining solid particles of pure carbon with a precursor that can be

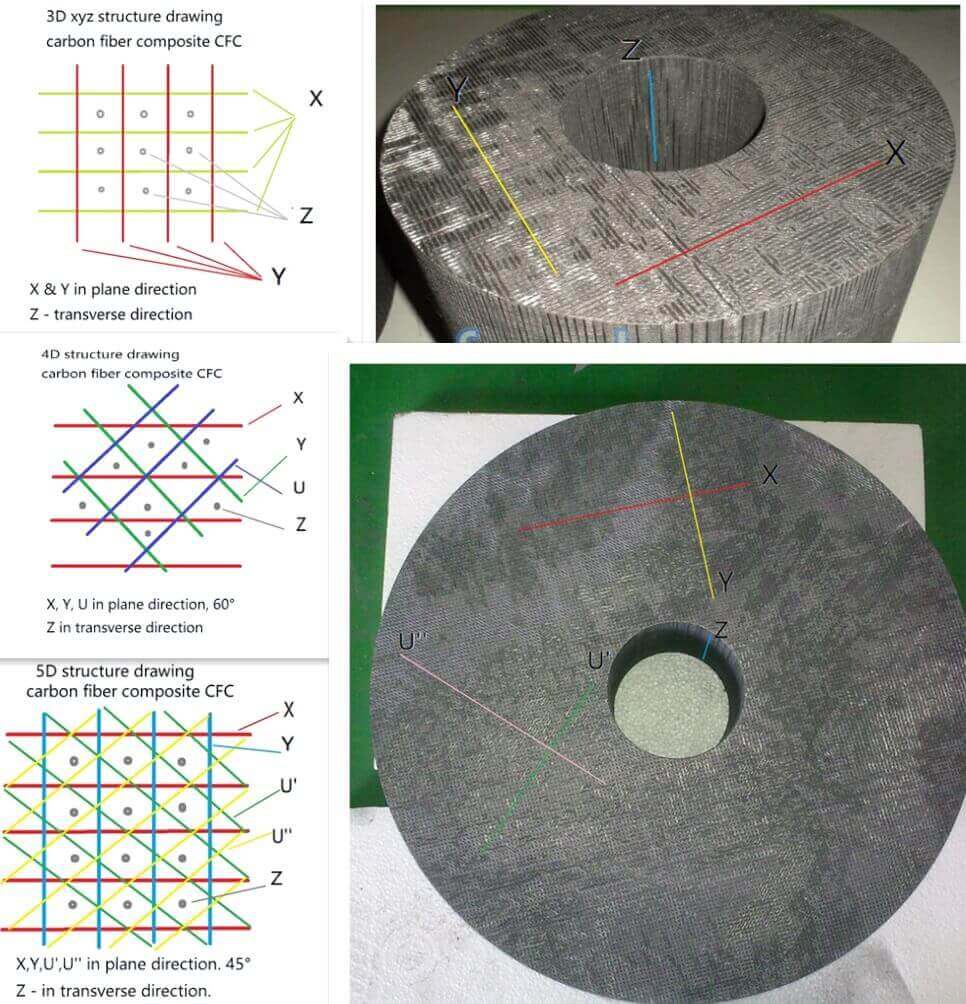

3D4D5D carbon fiber composite CFC structural diagram drawing material (2)

carbonized to serve as a binder. In CC composites, carbon fibers are used as the primary carbon instead of the filler coke. Unfortunately, the mass loss and shrinkage of the matrix during carbonization result in a final material that exhibits considerable bulk porosity.

The objective of repeated infiltration-pyrolysis is to densify the initial porous skeleton. Densification is achieved by impregnation with liquid or gaseous carbon precursor compounds and subsequent pyrolysis. A key factor in the selection of a matrix carbon precursor involves the ability to fully densify the preform and to achieve a high char yield.

Three basic methods of fabricating carbon fiber reinforced carbon materials exist. The first two methods are based on thermally degrading a thermosetting resin or a thermoplastic pitch. The third method involves depositing carbon into a fibrous preform using CVI. As discussed in a following section, the choice of fabrication method depends to a major extent on the geometry of the part being processed. Thin sections are prime candidates for CVI processing; however , since this method tends to preferentially deposit in and on the surface layers, it is not suitable for the fabrication of thick sections. Thick sections therefore tend to be produced using resin or pitch infiltration. Thermosetting resins remain solid during carbonization; however, pitches soften and tend to flow from a preform at high temperatures;

3D 4D CFC carbon fiber composite preform-preforming-Prefab (3)

Therefore, they require containment during the carbonization step. Complex shapes are difficult to fabricate using either CVI or pitch matrix materials owing to the difficulty of maintaining the dry fiber preform shape during the initial infiltration. Hybrid densification are sometimes practiced when a rigid structure is first made using the resin prepreg, autoclave molding process. In this process after carbonization, subsequent infiltration are made with CVI or pitch.

A recent development allows the impregnation of thin-section carbonaceous preforms with 100 percent mesophase. Carbonization can then be achieved after an oxidation step has rendered the mesophase infusible.

related news /articles:

Fabric preforms of carbon-carbon composite structures

Thermal conductivity data of carbon-carbon composite materials (2)

Development concerns (3)-Fabrication challenges of carbon carbon composite

Face sheet fabrication, characterization & Thermal conductivity testing