The electrical resistivity of the graphite crystal was reviewed in Ch.3, Ch.5. The crystal has a high degree of electrical anisotropy with resistivity that is low in the ab directions and high in the c direction. Molded graphite (even the isostatically molded material where the crystallites are essentially random) have higher resistivity than the single-crystal in the ab directions, but can stall be considered electrical conductors.

Table 5.9 lists electrical-resistivity values of several molded carbons and graphites and selected low-resistivity metals.

Table 5.9. Electrical resistivity of molded graphite and selected metals.

| Material | Electrical resistivity

At 25C, uom-m |

| Molded carbon

Electrographite(from petroleum coke) Electrographite (from lampblack) Pyrolytic graphite (ab direction) Aluminum Copper Tungsten Silver |

– 50

7.6 30.5 2.5-5.0 0.026 0.017 0.056 0.016 |

The values listed above for the molded carbons and graphites are averages and may vary depending on the raw materials, the process, and the degree of graphitization.

The electrical resistivity of molded graphite, like that of the graphite crystal and metals, increases with

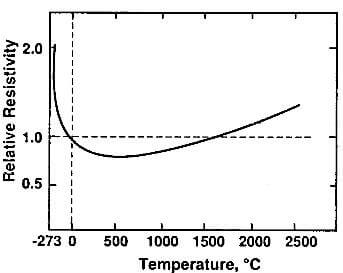

fig.5.10-relative variation of electrical resistivity of molded graphite as a function of temperature

temperature, above approximately 400C, and the material has the positive temperature coefficient of resistance which is typical of metals. Below 400C, the coefficient is usually slightly negative. At high temperature, graphite becomes a better conductor than the most-conductive refractory metal. The effect of temperature on the relative resistivity of molded graphite is shown graphically in Fig.5.10.

Emissivity: emissivity is the ratio of the energy radiated by a body to that radiated by an equal area of a perfect black body. According to the Stefan-Boltzmann law, a perfect black body is an ideal material which radiates the maximum amount of energy. The emissivity of a material depends on its structure and on its surface conditions.

Molded graphite, being black, has high emissivity, which is an important advantage in high-temperature applications. Table 5.10 lists the total emissivity of several carbon and graphite materials and selected metals for comparison.

Table 5.10. Emissivity of carbon and graphite materials and selected metals.

| Material | Total emissivity |

| Graphite (petroleum-coke based)

Graphite (lampblack based) Molded carbon Lampblack Silver Nickel, oxidized Tunsten, polished |

0.70-0.90

0.85-0.95 0.60-0.80 090-0.99 0.04 0.87 0.15 |