Solid oxide fuel cell (SOFC): This is a cell where the electrolyte is Y2O3 stabilized with ZrO2, operating at 800-1000C. SOFCs have an efficiency similar to MCFCs. The high operating temperature allows internal reforming, but suitable material of fabrication are an issue. The CO is generated from the water gas shift reaction that occurs within the cell.

The reactions occurring are:

Anode H2 + O— → H2O + 2e–

Cathode O2/2 + 2e– → O—

Cell H2 + O2/2 → H2O

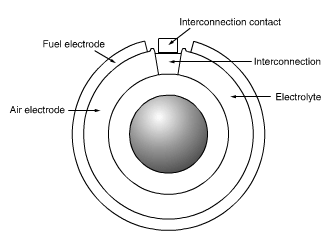

fig.23.12-solid oxide fuel cell

Westinghouse electric corporation manufacture solid oxide fuel cells and figure 23.12 shows a schematic cross-section of such a cell, typically tubular in design. The original design had a porous zirconia support tube which was replaced by using the air electrode as the basic support. Pressurizing the cell increases the efficiency to about 70%. Westinghouse has designed a 100KW unit comprising 1152 tubular cells 150 cm long and 22 mm in diameter. Flat plate designs are under investigation in the USA by Allied signal aerospace co., ceramtec inc and ztek inc.

Fuel cells have a great potential for energy saving and provide a cleaner energy conversion, but at present are too expensive. For a fuel cell using H2, the efficiency decreases with increasing temperature. The O2 supply must be free from compressor oil entrainment.

Each type of fuel cell tends to be specific to a given manufacturer and information on the construction is highly proprietary. Ogawa and shimizaka studied the effects of carbonization and surface treatment conditions on the performance of redox flow battery using PAN based carbon fibers.

Carbon fiber can certainly be used for PEM fuel cells. Lydall have introduced Lyflex GDL, a flexible microporous carbon nonwoven, for PEM fuel cells.

Graftech have patented a flexible graphite composite material for a PEM fuel cell electrode.

A combination of Pt/C/Teflon have been coated on a carbon cloth and hot pressed to a membrane obtaining 0.45 g/cm2 Pt and used in PEM cells.

The proton exchange membrane fuel cell manufactured by BZallard systems comprises of a stack of some 100-200 carbon plates acting as electrodes and ionizing H2 and O2 at 90C, which powers the fuel cells. The intended application is in trucks and automobiles.

Toray market a porous carbon paper and carbon cloth which can be pretreated with Teflon in a hydrophobic form and can then be used directly for electrode manufacturing. It is able to conuct a current, support a catalyst and allow gases and liquids to pass through.