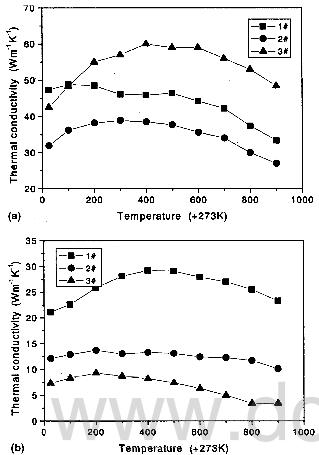

Fig.5 shows the effect of the preform architecture on the TC of the three carbon composites. Their TC in the X-Y and Z directons increases and subsequently declines with increasing temperature. Under the same temperature conditions, TC of composite 3# is the higest in the X-Y direction in the range 25-900C, but that of composite 1# is the highest in the Z direction, which mainly results from the differences of the preform architectures.

In the C/C composites, the CF is the channels of heat transmission; so its direction, dimension, and di

fig.5-effect of perform architecture on TC of the composites (a) x-y (b) Z

stribution in the preform have an important effect on the TC of the materials. For composite 3#, its preform is made of 1 k plain carbon cloth that has the highest frequency of yarn interlacing and a higher level of structure integrity, and the fibers and apertures in the preform are uniformly distributed in the X-Y direction, so the preform itself is compact, and homogeneous in the texture compared with another two preforms. After it is densified, many apertures and large holes in the preform are filled, and composite 3# becomes compact, only few micropores can be observed. Therefore it has the biggest TC in the X-Y direction, but its value is the lowest in the Z direction owning to no CF, and a large difference of the TC in both directions comes into being. For composite 1#, there are not only a number of long CF in the X-Y direction, but also some needle-pricked CF in the Z direction, in spite of very few amount, but it has a higher TC in the X-Y and Z direction. For composite 2#, its preform consists of the discontinuous short fibers which are distributed disorderly, directs at random, consequently its TC is the lowest in the X-Y direction, but because a few CF is distributed at random in the Z direction, its TC is higher than that of composite 3# in this direction.

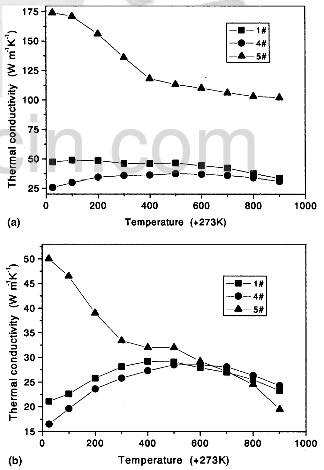

Fig.6 shows the effect of the PyC microstructures on the TC of three C/C composites in the X-Y and Z direction. From Figs.5 and 6, their TC values in the X-Y direction are much

fig.6-effect of PyrC microstructures on TC of the composites (a) x-y (b) Z

larger than in the Z direction, so the PyC microstructures have very strong effect on the TC of the C/C composites in the X-Y and Z direction. Composite 5# possessing the microstructure of RL PyC, has much higher TC than that of composite 1# and 4# under some temperature conditions, especially in the X-Y direction. Also, the TC of composites decreases with the increase of the temperature, but that of composite 5# decreases sharply with the increase of the temperature.

The porosity of composite 5# is the lowest. Obviously if the higher the porosity is, the more discontinous PyC, which brings more obstacle to the heat transmission. A large heat transmission difference exists in three kinds of PyC, and their heat transmission performance of SL PyC is better than that of ISO and less than that of RL due to their different porosity, so composite 5# has the highest TC under the same conditions owing its RL PyC.