A test was performed that isolated the effects of fringe and scattered ions from the backscattered particles. This was done by rotating the target normal direction to β=-70° while leaving the QCM at a high positive polar angle. The results from this test showed that fringe ions and scattered fast particles accounted for nearly all of the negative readings that were recorded during sputtering tests. It is noted that this test was repeated at all of the xenon ion energies studied in this program, and the correction due to fringe and scattered ions was taken into account in the plots and data lists contained in the results section below.

To improve problmes caused by a poorly focused ion beam at low ion energies, new gridlets were fabricated from POCO graphite sheets, which are shown in Fig.6. The screen and accel grid hole diameters were 0.95mm and 0.64mm, respectively- about half the size of NSTAR apertures. The gridlet assembly shown in fig.6b was used to take all sputter yield data at 200 and 300 eV.

Results:

The results of this study are presented in three sections. The first section presents data measured with a pyrolytic graphite target while the second one presents data for a carbon-carbon composite target. The third section compares and contrasts the PG and CC data to each other and to measurements made by other researchers. In this section, comparisons of PG and CC data to molybdenum measurements are also made and a simple model is presented that predicts the life time enhancement of ion optics systems that use carbon-based materials rather than conventional refactory materials like molybdenum and titanium.

Pyrolytic graphite sputter measurements:

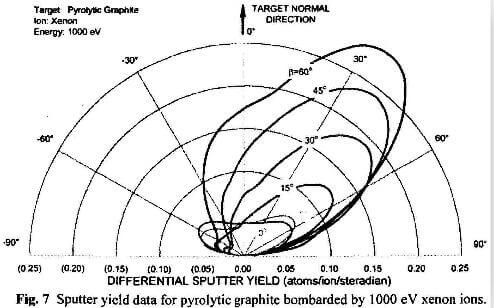

Figures 7 through 12 contain differential sputter yield data for PG that demonstrate the effects of xenon ion energy and angle of

fig.7-sputter-yield-data-for-pyrolytic-graphite-bombarded-by-1000-eV-xenon-ions

incidence. Figure 7 contains polar plots of data collected at 1000 eV for angles of incidence of 1, 5, 15,30, 45, and 60°. The individual data points are not shown on the curves to reduce clutter on the figure, however, the data points scatter about the curves in a manner similar to that shown in figs.2 and 3.

In fig.7 note the dramatic difference between data taken at normal incidence (0°) and at an incidence angle of only 5°. The high sensitivity of the differential sputter yield measurements to incidence angle forced us to very carefully adjust the target normal and ion beam directions prior to taking measurements. In addition, the ion beam was aligned so that it would strike a position very close to the center of the target. To ensure this condition, we placed a thin tantalum foil plate directly into the ion beam at a location that was less than 1.0 cm above the center of the target. The tantalum foil indicated the beam center by glowing red at that location when the ion beam was directed onto it. The tantalum foil was mounted on a rod which could be both rotated and pushed inot hte vacuum system via a feed-through. In this way, the probe could be moved over the target to check beam alignment, and ten be rotated underneath the water cooled target where it would be protected from the beam when not in use. This could all be done while the system was under vacuum and while the ion beam was operating under steady state conditions.

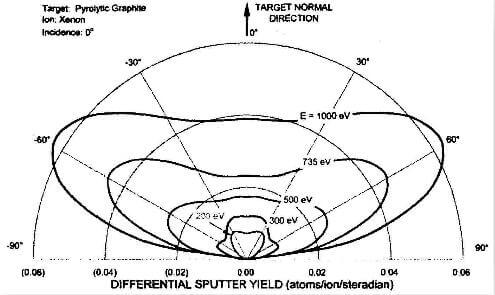

fig.8-sputter yield data for pyrolytic graphite bombarded at normal incidence

After carefully aligning the ion beam to the target, the data shown in fig.8 were collected at normal incidence over a range of ion energies from 200 eV to 1000 eV. It is interesting to note the shift from under cosine behavior that atoms knocked into high polar angle directions may not obtain enough energy to overcome the surface binding energy and escape from the surface with high probability.