Many workers have published results on the compression testing of cfrp. Kumar and Helminiak have reported that the ratios of compressive strength to tensile strength, when evaluated from composite data, can vary in the range 0.2-1.0. It is normal to employ the rule of mixtures and a favourable relationship was reported by Ewins and Ham. However, the application of the rule of mixtures for composites does not always give meaningful results and can be overcome by measuring the compressive strength of a single filament embedded in a resin.

Several methods have been used to determine the compression strength of carbon fiber and its composites. The loop test; Single filament in a Beam; critical length under compression; micro-compression; fiber recoil; piezo method; raman spectroscopy; composite and mini-composite.

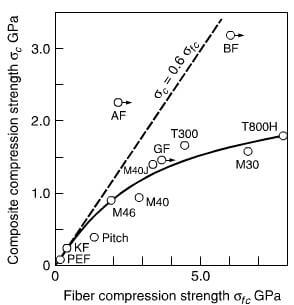

It has been suggested that the compressive strength of a carbon fiber composite may be a system property rather than a material property. The single fiber compressive strength tends to increase as the fiber strength when measured by the single fiber loop test. But there is considerable deviation of the composite and single filament compressive strengths and an increase in fiber strength does not assure an increase in composite compressive strength, see figure 20.17. The composite compressive strength is much lower than the tensile strength, about one half, and the compressive strength of a pitch based carbon fiber is lower than a PAN based carbon fiber.

fig.20.17-compression strength of single carbon fibers vs composite compression strength

The compressive stress decreases with increased anisotropy, which can be represented by the ratio of fiber tensile modulus to the torsional modulus. Kumar has shown that the compressive strength decreases with increasing Young’s modulus, whilst Northolt et al showed that the compressive strength increases as the shear modulus.

Dobb et al studied PAN and mesophase pitch based carbon fibers by measuring their compressional properties using the recoil test and have stated that the compression strength of carbon fibers is influenced by a combination of various structural features, rather than by any single feature.

PAN type carbon fibers fail by transverse in the laminae could cause a shear mode of failure. If the shear strength is less than the buckling strength, then shear failure will occur in preference to buckling. However, Ewins and Potter showed that microbuckling does occur as the temperature approaches the Tg. The failure starts as a crack on the tensile side of the bent fiber, which propagates to a kink band on the compressive side. The failure transition is dependent on the shear modulus of the matrix and the shear strength of the fiber. Increase in fiber strength and the uptake of water, which decreases resin modulus, will have the same effect.

It was suggested that larger diameter carbon fiber could exhibit higher compressive strength, but we have found no evidence for this.