Title: Innovating High-Temperature Solutions: Carbon & Graphite Insulation Boards | Rigid Graphite Felts

August 20, 2025 — As all industries worldwide seeking advanced thermal management materials for extreme environments, CFC Carbon Co., Ltd. emerges as a global leader in manufacturing high-performance carbon and graphite insulation boards and rigid graphite felts. With decades of expertise and patented technologies, the company delivers unmatched quality, cost efficiency, and reliability to sectors including aerospace, metallurgy, and energy, high-temp furnaces, vacuum furances.

1. Advanced Materials for Extreme Conditions

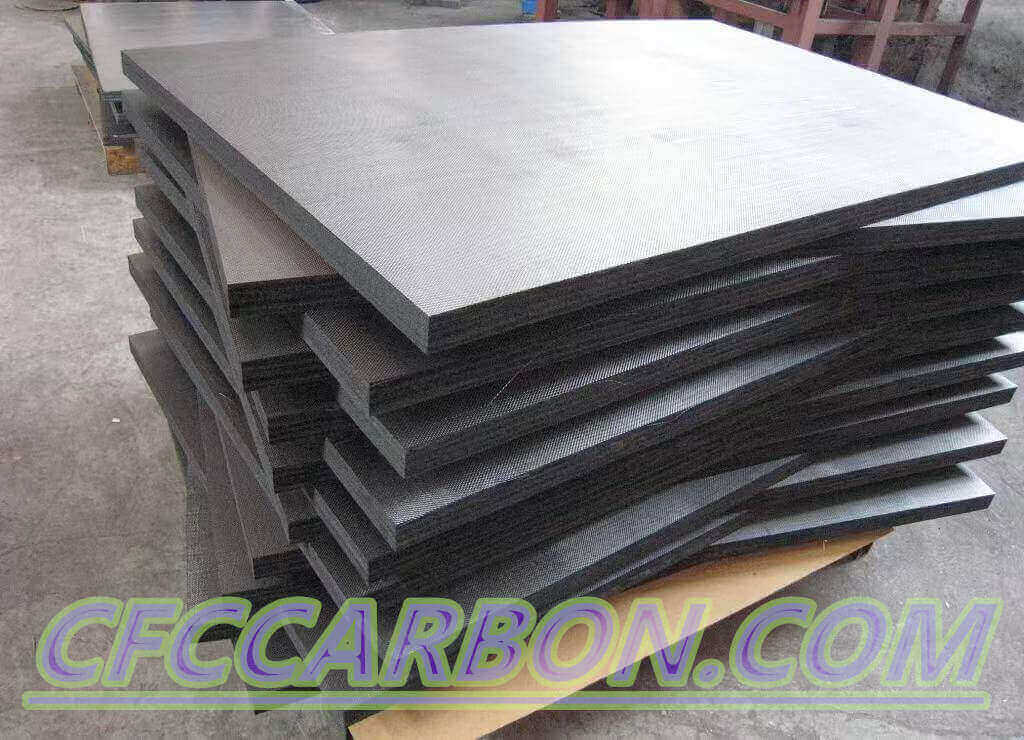

carbon graphite felt insulation soft hard rigid board short long fiber chopped material manufacturer factory China (13)

Carbon and graphite insulation materials are engineered to withstand temperatures exceeding 2000°C while maintaining structural integrity. Unlike conventional ceramics, these materials combine high-purity graphite matrices with reinforced carbon fibers to achieve:

-

Ultra-Low Thermal Conductivity (as low as 0.05 W/m·K at 1000°C).

-

Exceptional Thermal Shock Resistance, ensuring stability under rapid temperature fluctuations.

-

Lightweight Properties (density: 0.2–1.2 g/cm³), reducing energy consumption in industrial furnaces by 20–40%.

CFC Carbon’s products are tailored for diverse applications, including:

-

Vacuum Furnaces: Rigid graphite felts provide seamless insulation for crystal growth systems.

-

Aerospace: Insulation boards protect critical components in rocket nozzles and re-entry vehicles.

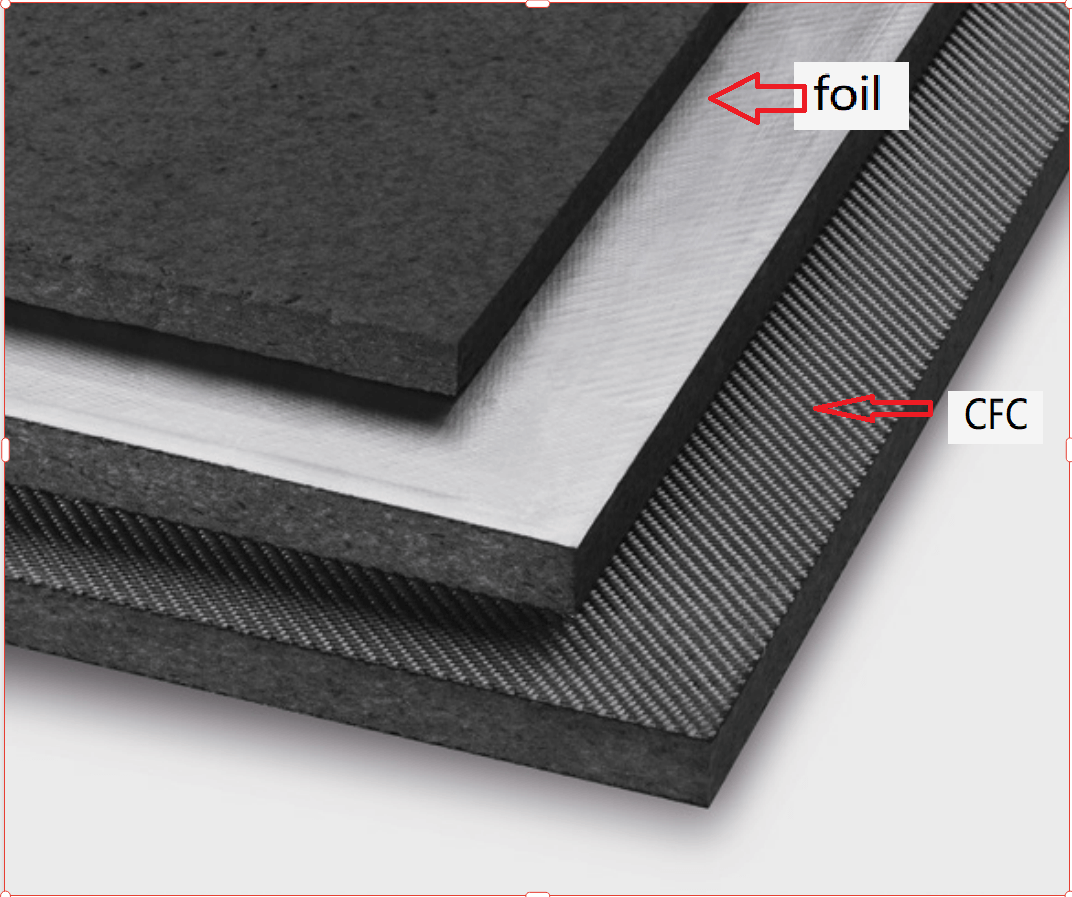

rigid carbon graphite felt insulation boards surface processing+foil+CFC

-

Metallurgy: Linings for aluminum reduction cells enhance durability and reduce maintenance costs.

2. Proprietary Manufacturing Process

CFC Carbon’s innovation lies in its Ultra-High-Pressure Impregnation Carbonization (UHPIC) technology, which accelerates production cycles by 50–70% while enhancing material performance:

-

Preform Fabrication: Carbon fibers (PAN-based T700/T300) are woven into 2D, 2.5D, or 3D architectures tailored to client specifications.

-

Matrix Densification:

-

Liquid Precursor Route: Coal tar pitch or phenolic resin impregnation under 100 MPa pressure.

-

Gas-Phase Route: Chemical Vapor Infiltration (CVI) deposits pyrolytic carbon for uniform density (>1.95 g/cm³).

-

-

Fast Carbonization: Rapid heating (1000°C/min) to 2500°C minimizes residual stress and optimizes graphitization.

This process ensures higher oxidation resistance and mechanical strength compared to industry standards.

3. Key Product Specifications

CFC Carbon’s products outperform competitors in critical metrics:

| Property | Graphite Insulation Boards | Rigid Graphite Felts | Industry Average |

|---|---|---|---|

| Max Service Temperature | 3000°C (inert) | 2200°C (with SiC coating) | 2800°C |

| Density | 0.6–1.2 g/cm³ | 0.2–0.6 g/cm³ | 0.7–1.5 g/cm³ |

| Thermal Conductivity | 0.05–0.3 W/m·K | 0.1–0.4 W/m·K | 0.1–0.5 W/m·K |

| Compressive Strength | 15–20 MPa | 5–10 MPa | 10–15 MPa |

| Oxidation Resistance | Excellent (SiC-coated) | High (1200°C in air) | Moderate |

Data sourced from CFC Carbon’s technical documentation and independent testing reports.

Product properties /data sheet comparison and prices:

| Types | Laminated /Sandwich | short fiber /integral | ||

| Grade name | PRF-3 | RRF-3 | RRF-3W | RRF-3WP |

| Material type | PAN, long fiber, laminated. | Rayon, long fiber, laminated. | Rayon, short fiber, molded, integral | purified RRF-3W |

| Standard size /mm | 1800-1500-(20-200) | 1600-1260-460 | ||

| Carbon content | ≥99.9% | ≥99.9% | ≥99.92% | ≥99.99% |

| Ash content | 500PPM | 500PPM | ≤800PPM | ≤20PPM |

| Bulk density /g/cm3 | 0.20~0.30 | 0.18~0.22 | 0.17±0.01 | |

| Thermal conductivity (25°C) | <0.20W/m.K | <0.10W/m.K | <0.10W/m.K | |

| Thermal conductivity (1000°C) | <0.70W/m.K | <0.50W/m.K | <0.30W/m.K | |

| Compressive strength /Mpa | 1.2 | 0.9 | 0.7 | |

| Bending strength /Mpa | 1.5 | 1.1 | 0.9 | |

| Processing temperature | 2000 ℃ | 2000 ℃ | 2100 ℃ | |

| Application temperature (Vacuum/inert gases) |

1200~2500 ℃ | 1600~2500 ℃ | 1600~3000 ℃ | |

| Application temperature (Oxygen) |

≤400 ℃ | ≤450 ℃ | ≤400 ℃ | |

| Price $/kgs EXW basis. | 37.5 | 57 | 95 | 128 |

| Density for w.t calculation | 0.25g/cm3 | 0.20g/cm3 | 0.18g/cm3 | |

| Additional Process | with foil and or CFC, or coating, purification (≤20PPM) | with foil and or CFC, or coating, purification (≤20PPM) | with coating | |

Product applications

It is mainly used in single crystal furnace, polycrystalline furnace, semiconductor industry, and can also be used in powder metallurgy industrial furnace, vacuum sintering furnace, etc.

Product Specifications

Customized services can be provided, product specifications, thickness, raw materials and surface coatings can be customized.

Please check the data sheet/properties of rigid graphite felt, Graphite Insulation Boards at: https://www.cfccarbon.com/wp-content/uploads/2025/08/0304-Rigid-graphite-felt-board-ENGLISH-2.pdf

4. Competitive Advantages: Why Choose CFC Carbon?

Semiconductor, rigid, graphite, felt, optical fiber, sapphire, silicon carbide, crystal growth, epitaxy, thermal equipment, Rayon, short fiber, SGL, third-generation, material, manufacturer, (3)

-

Cost Efficiency: Direct manufacturing and economies of scale enable 15–20% lower pricing than competitors (e.g., SGL Carbon, Mersen) without compromising quality.

-

Rapid Delivery: Standard orders fulfilled within 2–3 weeks (30% faster than market average) due to streamlined logistics.

-

Robust Packaging: Triple-layer waterproof and shock-absorbent materials ensure damage-free global shipping.

-

Technical Expertise: 45+ years of R&D experience2, with support for custom designs (e.g., non-standard shapes, hybrid coatings).

-

Free Samples: Pre-production samples provided for client testing and validation.

5. Global Impact and Sustainability

CFC Carbon’s materials contribute to energy efficiency and sustainability:

-

Energy Savings: Low thermal conductivity reduces furnace energy consumption by 20–40% in steel and aluminum plants.

-

Longevity: Products last 3–5× longer than ceramic alternatives, reducing waste.

-

Recyclability: Graphite scraps are repurposed for lower-grade applications, minimizing environmental impact.

6. Connect with CFC Carbon

Experience the synergy of quality, affordability, and innovation. Contact us for tailored solutions:

-

Explore Products: Graphite Insulation Boards | Rigid Graphite Felts

-

Direct Inquiry: Email

potter@cfccarbon.comor call+86-18910941489(whatsapp). -

Global Shipping: Facilities in Beijing support worldwide distribution with real-time tracking.

Request your free sample today and join 500+ industrial partners trusting CFC Carbon for extreme-temperature success.

related news /articles:

Rigid graphite felt parts, machined rigid graphite felt

03-Rigid carbon graphite felt board-data sheet

Heat conduction mechanism of carbon-carbon composites

Thermal insulation graphite barrel