Introduction to Carbon Fiber Composites

Carbon fiber composites (CFCs) are high-performance materials composed of carbon fibers embedded in a polymer matrix, typically epoxy, vinyl ester, or thermoplastic resins. These materials are classified into thermoset and thermoplastic composites, with further variations based on fiber orientation (unidirectional, woven, or chopped). Renowned for their exceptional strength-to-weight ratio, corrosion resistance, and fatigue performance, carbon fiber composites are widely used in aerospace, automotive, wind energy, and sports equipment industries. The future of CFCs lies in cost reduction, recyclability, and enhanced manufacturing techniques like automated fiber placement (AFP) and 3D printing.

Manufacturing Process of Carbon Fiber Composites

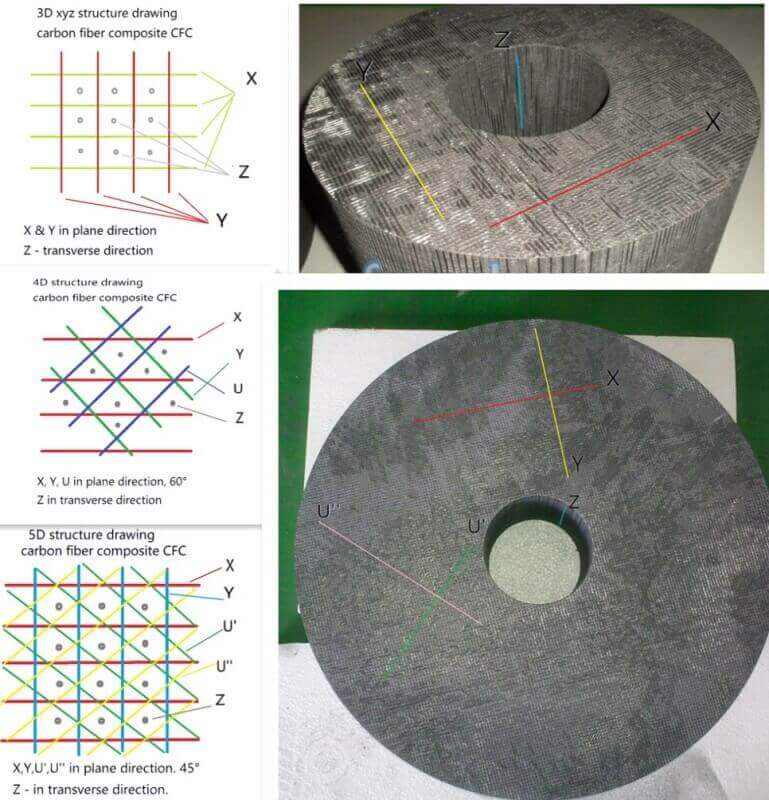

3D4D5D carbon fiber composite CFC structural diagram drawing material (1)

The production of carbon fiber composites involves several critical steps, each contributing to the material’s superior properties. The process begins with precursor preparation, where polyacrylonitrile (PAN) or pitch-based fibers are oxidized and carbonized at high temperatures. Next, the weaving or layering process arranges fibers into desired orientations (unidirectional, bidirectional, or multidirectional).

The resin infusion stage follows, where the fiber reinforcement is impregnated with a polymer matrix through methods like hand lay-up, resin transfer molding (RTM), or prepreg curing. Curing under controlled heat and pressure ensures optimal consolidation, while post-processing (trimming, machining, and coating) finalizes the product. Advanced techniques like automated tape laying (ATL) and out-of-autoclave (OoA) curing are revolutionizing production efficiency and scalability.

Key Properties of Carbon Fiber Composites

Carbon fiber composites exhibit unparalleled mechanical properties, including:

- High Strength & Stiffness: With a tensile strength exceeding 5000 MPa, CFCs outperform steel and aluminum while being significantly lighter.

- Lightweight: Their low density (1.5-2.0 g/cm³) makes them ideal for weight-sensitive applications like aircraft and electric vehicles.

- Corrosion & Fatigue Resistance: Unlike metals, CFCs resist rust and degradation, ensuring longevity in harsh environments.

- Thermal & Electrical Conductivity: Certain formulations offer excellent heat dissipation and electromagnetic shielding.

- Design Flexibility: Tailored fiber orientations allow engineers to optimize strength in specific load directions.

Applications Across Industries

The versatility of carbon fiber composites has led to widespread adoption in:

- Aerospace: Aircraft fuselages, wings, and rotor blades benefit from weight reduction and fuel efficiency.

- Automotive: High-end cars and EVs use CFCs for chassis, body panels, and battery enclosures.

- Wind Energy: Turbine blades leverage CFCs’ durability and fatigue resistance.

- Sports & Leisure: Bicycles, golf clubs, and tennis rackets utilize their lightweight and high-performance characteristics.

Future Trends in Carbon Fiber Composites

The industry is shifting toward sustainable production, with bio-based resins and recyclable thermoplastics gaining traction. Automation and AI-driven manufacturing are reducing costs, while nanotechnology-enhanced composites promise even greater strength and multifunctionality. Companies like CFC Carbon are at the forefront, developing next-gen solutions for a greener, stronger future.

Conclusion

As a leading carbon fiber composite manufacturer, advancements in material science and production techniques continue to expand the boundaries of what CFCs can achieve. From aerospace to renewable energy, these materials are redefining performance standards, offering unmatched strength, durability, and efficiency. The ongoing push for sustainability and innovation ensures carbon fiber composites will remain a cornerstone of modern engineering.

(For more details on carbon fiber products, visit CFC Carbon.)

related news /articles:

CVI CVD Carbon Carbon Composite Material, Manufacturer in China

3D Carbon fiber composite | CFC material manufacturer in China

Properties of 4D carbon carbon composite | C/C composite material

Difference between 2D and 2.5D carbon fiber composite material