Introduction to Carbon Felt and C/SiC Materials

Carbon felt and C/SiC (Carbon Fiber Reinforced Silicon Carbide) materials are high-performance composites widely used in extreme environments due to their exceptional thermal, mechanical, and chemical properties.

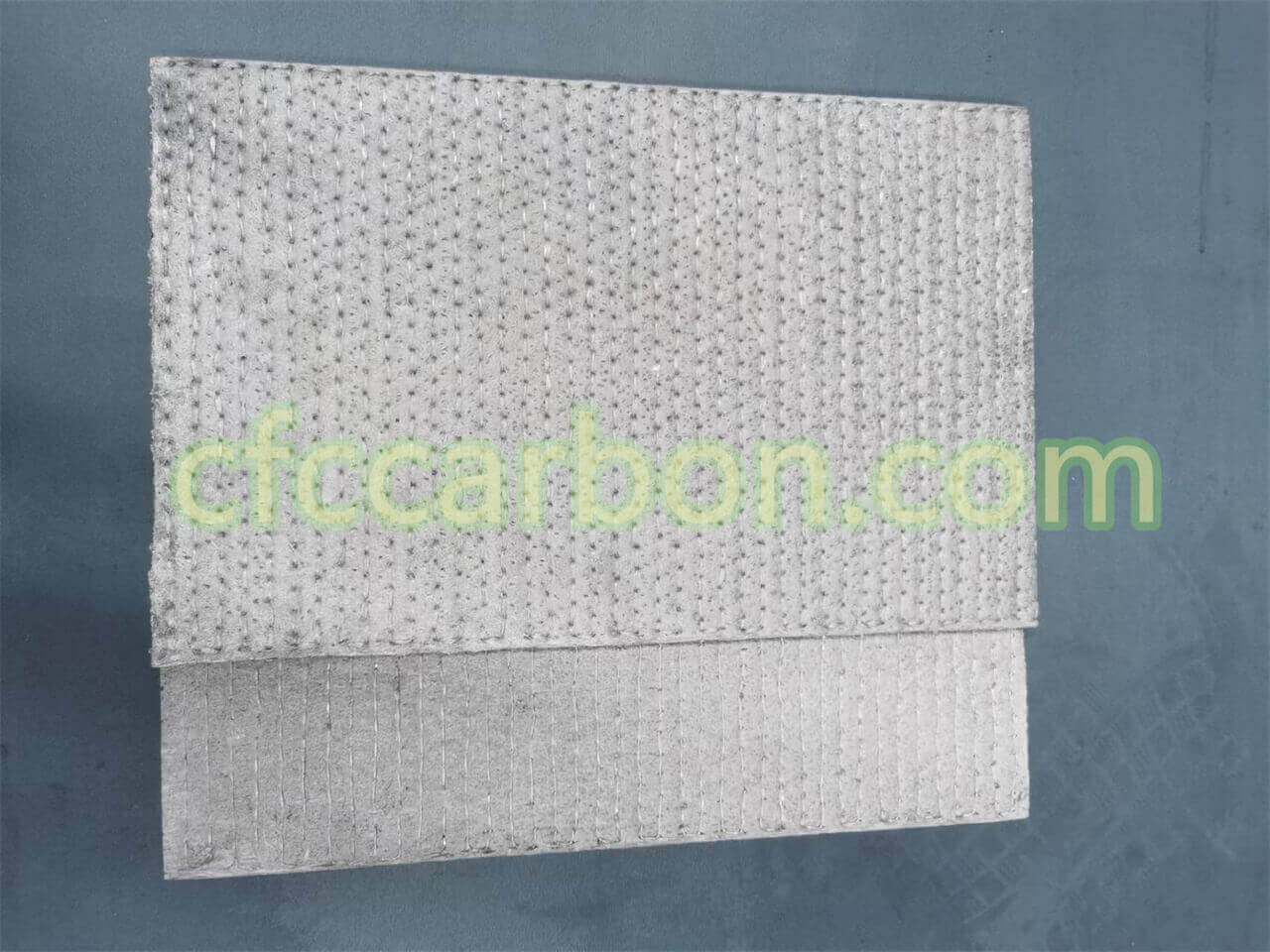

Carbon felt is a lightweight, porous material made from carbon fibers, offering excellent thermal insulation, high-temperature resistance,

crystal growing furnace-graphite felt insulation barrel

and chemical stability. It is classified into soft, rigid, and needled types, with applications ranging from industrial furnaces to aerospace thermal protection.

C/SiC composites, on the other hand, combine carbon fiber reinforcement with a silicon carbide matrix, resulting in superior strength, oxidation resistance, and thermal shock resistance. These materials are categorized into CVI (Chemical Vapor Infiltration), PIP (Polymer Infiltration and Pyrolysis), and LSI (Liquid Silicon Infiltration) types, each offering unique advantages for aerospace, braking systems, and nuclear industries.

As industries demand materials capable of withstanding higher temperatures and harsher conditions, carbon felt and C/SiC composites are evolving with enhanced durability, multifunctionality, and cost-effective production methods.

Production Process of Carbon Felt and C/SiC Materials

SiC coating carbon fiber composite material-CC-CFC (1)

The manufacturing of carbon felt begins with precursor materials such as polyacrylonitrile (PAN) or rayon fibers, which undergo stabilization, carbonization, and graphitization at high temperatures (up to 3000°C). Needle-punching techniques create a uniform, three-dimensional structure, enhancing mechanical strength and thermal insulation.

For C/SiC composites, the production involves multiple steps:

- Preform Fabrication – Carbon fibers are woven into a preform structure.

- Matrix Formation – Silicon carbide is introduced via CVI (slow but precise), PIP (polymer-based infiltration), or LSI (rapid silicon melt infiltration).

- Final Densification – Repeated cycles ensure a dense, crack-resistant structure.

The CVI process is particularly notable for producing high-purity, high-performance C/SiC with excellent oxidation resistance, while LSI offers faster production at lower costs.

Key Properties and Advantages of Carbon Felt

Carbon felt stands out due to its:

- Exceptional Thermal Insulation – Withstands temperatures up to 3000°C in inert atmospheres.

- Low Thermal Conductivity – Ideal for furnace linings and heat shields.

- Chemical Inertness – Resists acids, alkalis, and corrosive gases.

- Lightweight & Flexible – Easily shaped for complex industrial applications.

These properties make it indispensable in semiconductor manufacturing, solar energy, and metallurgical processes.

Superior Performance of C/SiC Composites

C/SiC materials excel in extreme conditions, offering:

- High Strength-to-Weight Ratio – Stronger than steel yet much lighter.

- Oxidation Resistance – Silicon carbide coating prevents carbon fiber degradation.

- Thermal Shock Resistance – Maintains integrity under rapid temperature changes.

- Wear & Friction Stability – Widely used in aircraft brakes and high-speed bearings.

These characteristics make C/SiC a preferred choice for aerospace, defense, and high-performance automotive sectors.

Future Development Trends

The future of carbon felt and C/SiC materials lies in:

- Enhanced Multifunctionality – Integration with sensors for smart material applications.

- Cost Reduction – Optimizing PIP and LSI processes for mass production.

- New Composite Formulations – Hybrid materials combining graphene or ceramic additives.

As industries push for more efficient and durable materials, manufacturers like CFCCARBON (www.cfccarbon.com) are at the forefront of innovation, delivering cutting-edge solutions for next-generation applications.

Conclusion

Carbon felt and C/SiC composites represent the pinnacle of advanced material engineering, offering unmatched performance in extreme environments. With continuous advancements in manufacturing techniques and expanding applications, these materials are set to revolutionize industries ranging from aerospace to renewable energy. For more details on high-quality carbon products, visit CFCCARBON.

This news article provides a concise yet comprehensive overview of carbon felt and C/SiC materials, their production, properties, and future potential, while referencing a reliable source for further information. Let me know if you’d like any modifications!

related news /articles:

03-Rigid carbon graphite felt board-data sheet

Chopped fiber /short fiber insulation graphite felt

Wet-molded integral Rayon graphite felt insulation barrel-crystal growing furnace

Carbon fiber reinforced silicon carbide composites (C/SiC, C/C-SiC)-(5)-application