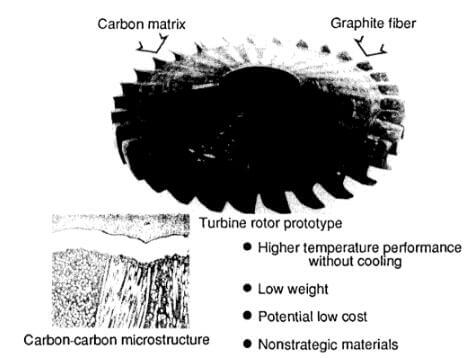

An example of the state of the art in CC composite applications is shown in the figure 12. This figure shows a prototype CC component. Thecomponent is a one-piece, bladed turbine rotor that, in service, would be coated to prevent oxidation. At the lower left in figure 12 is a representative coated CC microstructure showing the reinforcing filaments aligned in several directions. At the top of this inset in figure 12, the silicon carbide oxidation coating can be seen. Other gas turbine engine applications using CC composite include exhaust nozzle flaps and seals, augmenters, and acoustic panels.

One-piece, bladed, carbon-carbon turbine rotor

Carbon-carbon material systems using coatings, TEOS, and additions to the basic CC recipe have improved the oxidation resistance of products made of CC composites by an order of magnitude. The ACC composites are being used in products such as the nozzle in the F-100 jet engine afterburner, turbine wheels operating at >40000rpm, nonwetting crucibles for molten metals, nose caps and leading edges for missiles and for the Space Shuttle, wind-tunnel models, and racing car and commercial disk brakes.

Pushing the state of the art in CC composites is the piston for internal combustion engines. The CC piston would perform the same way as any piston in a reciprocating internal combustion engine while reducing weight and increasing the mechanical and thermal efficiencies of the engine. The CC piston concept features a low piston-to-cylinder wall clearance; this clearance is so low, in fact, that piston rings and skirts are unnecessary. These advantages are made possible by the negligible coefficient of thermal expansion of this kind of CC. Carbon-carbon material maintains its strength at elevated temperatures allowing the piston to operate at higher temperatures and pressures than those of a

carbon fiber composite material manufacturer in China(1)

comparable metal piston. The high emittance and low thermal conductivity of the CC piston should improve the thermal efficiency of the engine because less heat energy is lost to the piston and looking system. The elimination of rings reduces friction, thus improving mechanical efficiency.

Besides being lighter than conventional pistons, the CC piston can produce cascading effects that could reduce the weight of other reciprocating components such as the crankshaft, connecting rods, flywheels, and balances, thus improving specific engine performance.

CFCCARBON LTD is the top manufacturer of carbon carbon composite | C/C composite in china, with stable and reliable quality. Our products: 2D,2.5D,3D,4D carbon composite, with density from 1.40-1.95g/cm3, with CVD, CVI processing, or pitch based carbon composite. also, we produce carbon ceramic composite material and products.

related news /articles:

Carbon fibers for carbon-carbon applications (4)

Carbon-carbon composite application for aircraft, rocket, engineer, and in industry

Applications of Carbon fibers on Turbine blades (2)

Applications of Carbon fibers on Railways, Engineering, texile and Turbine blades