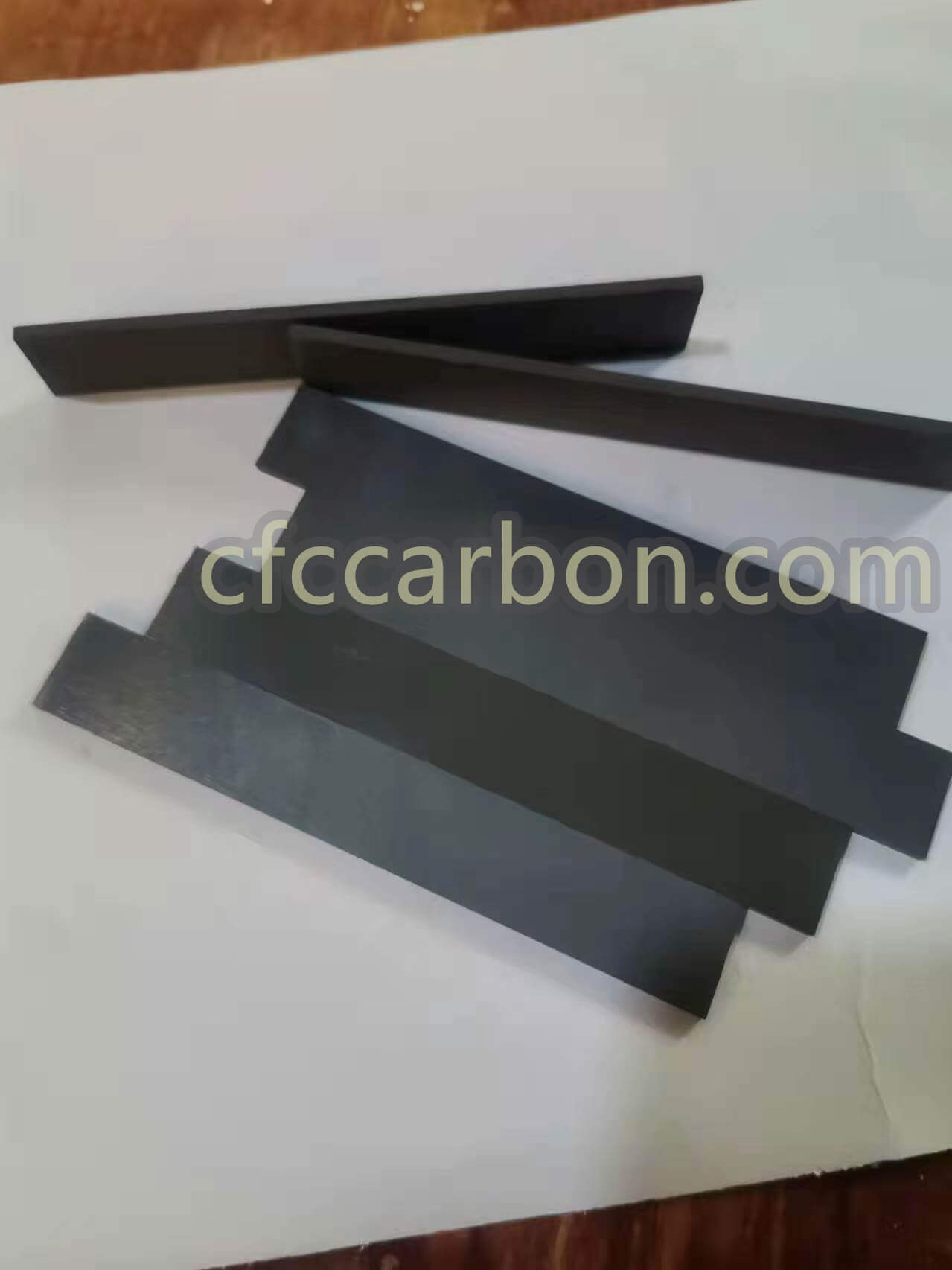

Impregnation graphite seal bearing, mechanical carbon graphite

Impregnated graphite material is a composite material that fills impregnating agents such as resin and metal into the pores of graphite through an impregnation process and then solidifies through heat treatment. By combining graphite with matrix materials such as resin, copper, antimony, etc., the conductivity, wear resistance or corrosion resistance of the matrix material can be improved.

resin, copper, antimony, impregnated, mechanical, seal, bearings, mould, pipe, tube, carbon, graphite, material, impregnation, manufacturer, factory, China

Detailed description

Impregnation graphite material is a composite material that fills impregnating agents such as resin and metal into the pores of graphite through an impregnation process and then solidifies through heat treatment. By combining graphite with matrix materials such as resin, copper, antimony, etc., the conductivity, wear resistance or corrosion resistance of the matrix material can be improved.

Main types of Impregnated graphite material are: Resin impregnated graphite, Copper impregnated graphite material, antimony impregnated graphite, silver impregnated graphite and others.

See some Typical types of impregnated graphite materials below:

Pure graphite material will volatile due to volatile substances in the adhesive and binder aggregation, decomposition and carbide, when baking, thus appeared the pore (10% ~ 30% porosity). If pure graphite Used as sealing ring, it will be permeable or leakage, and strength is low, so we fill the gap increased, and make it not permeability after resin process, it also increased the strength. But the heat resistance and corrosion resistance have varying degrees of decline. Impregnated material use mainly 3 types of material: organic resin, inorganic substances and metal.

Resin impregnated graphite: high density (up to 2.0-2.5g/cm³), but poor high temperature resistance (about 200℃ or less), suitable for corrosive environments;

resin impregnated graphite material is a composite material that is impregnated with synthetic resin into the surface and internal pores of graphite and then solidified through heat treatment. Its core feature is to improve the mechanical strength and corrosion resistance of graphite through the impregnation process while retaining its excellent thermal conductivity. main grade names that we produce: M106H, M120H, M106K,M120K, M254K

Metal impregnated graphite: Combines the high temperature resistance of graphite (up to 800°C or more) and the mechanical strength of metal to improve wear resistance and conductivity.

Copper impregnated graphite material uses carbon graphite as the base material and impregnates copper alloy through vacuum pressure.

Utilize the high hardness, good lubricity and chemical stability of carbon graphite as the base. Utilize the high melting point, ductility, high thermal conductivity and corrosion resistance of copper alloy to form a continuous, stable and high mechanical strength mechanical sealing material. Current products have been widely used in metallurgical continuous casting machine, rolling just equipment, mining machinery, shipping, steam turbine, water turbine, injection molding machine and equipment in the production line.

main grade name that we produce: M106P,M120P, M254P

Metal impregnated graphite also includes silver impregnated graphite, antimony impregnated graphite, aluminum impregnated graphite, Babbitt alloy impregnated graphite, etc.

Antimony impregnated graphite material is a kind of excellent self-lubrication antifriction material, it can be in high temperature of 500 ° C, cryogenic – 253 ° C, high speed 20000 RPM, high pressure 10 mpa, or high viscosity medium, especially suitable for medium such as water, oil, kerosene condition under the conditions of use.

Antimony metal does not dissolve in water, hydrochloric acid and strong alkali solution. Antimony in the case of increasing load and improve the speed and melting steel friction when rare phenomenon, therefore, leach antimony graphite materials can also be applied to medium such as water, hydrochloric acid, strong alkali. And leaching of antimony graphite material can be silicon carbide, tungsten carbide or stainless steel, etc. Main grade names that we produce: M106D,M120D, M254D.

You can see a video of mechanical graphite below:

Characteristics /properties of impregnated graphite materials:

In the field of materials science, impregnation graphite is a technology that impregnates graphite particles or flakes into other materials. By combining graphite with base materials such as resin, copper, antimony, etc., the conductivity, wear resistance or corrosion resistance of the base material can be improved. For example:

Fuel cell bipolar plates: Use carbon materials impregnated with graphite to improve conductivity;

Wear-resistant coating: Impregnate graphite into metal surfaces to enhance wear resistance.

In industrial equipment, impregnated graphite is often used to manufacture high-performance components:

High temperature environment: impregnation Graphite materials can withstand high temperatures and are used to manufacture equipment such as thermocouples and furnace linings;

Conductive components: Such as electrodes, conductive gaskets, etc., using the high conductivity of graphite.

“Impregnation graphite” mainly refers to the technology of combining graphite with other materials through an impregnation process, which is widely used in fields that improve material performance, such as energy, chemicals, machinery, etc.

Resin Impregnated graphite is a composite material that uses synthetic resin as an impregnating agent to fill the surface and internal pores of graphite, and then solidifies the resin through heat treatment. Its core feature is to combine graphite particles or sheets with matrix materials through the bonding effect of resin, thereby improving the mechanical properties and durability of the material

Advantages and characteristics of impregnation graphite:

It has the lightweight of graphite and the conductivity and corrosion resistance of impregnated materials;

At the same time, the material performance can be controlled by adjusting the amount of resin/metal impregnation;

Impregnated graphite materials have become core materials in the fields of chemical industry, metallurgy, machinery, etc. through chemical stability and physical properties, especially in corrosion resistance, wear resistance and high temperature scenes. It has an irreplaceable role. With the advancement of technology, its application scope is still expanding to emerging industries such as new energy and aerospace.

Main application areas of Impregnation graphite material:

Impregnation graphite materials have important applications in many industrial fields due to their corrosion resistance, wear resistance and thermal conductivity. The main application areas are as follows:

Chemical and petrochemical fields:

Corrosion-resistant equipment: used to manufacture reaction tanks, heat exchangers, condensers, combustion towers, etc., can handle acid, alkali, corrosive media, replace stainless steel and other metal materials, and save costs.

Seals and pump parts: used as sealing rings, piston rings and bearings in pumps, valves, pipelines and other equipment to prevent leakage of corrosive media, suitable for high temperature and high pressure environments.

Steel-making and casting: used as a carburizer and refractory component to increase the temperature and fluidity of molten steel, and also used for casting molds and crucibles.

Aluminum electrolytic cell: used for electrolytic cell lining, high temperature and corrosion resistance, to ensure the stability of the electrolysis process.

Mechanical and energy fields:

Wear-resistant lubricating materials: used as a replacement for lubricating oil in compressors, pumps and other equipment, wear-resistant and no lubricant required, with a wide operating temperature range (-200°C to 2000°C).

Electrodes and conductive parts: used for electrodes of arc furnaces and submerged arc furnaces, as well as telephone parts, TV picture tube coatings, etc., with excellent conductive properties.

High temperature environment: used as a refractory material in high temperature scenes such as glass melting and ceramic firing.

Nuclear industry and defense: used in special scenes such as radiation protection and high temperature sensors, taking advantage of its radiation resistance and high temperature resistance.

CFCCARBON is a manufacturer and exporter specializing in impregnated graphite materials and impregnated graphite products. Our products have stable quality, excellent performance, reasonable price and precise delivery time control. Over the years, we have won the trust and praise of customers all over the world with our high-quality services.

If you want to know more photos, material properties, product indicators, product prices, etc. of resin graphite materials, copper graphite materials, antimony impregnated graphite materials, etc., please feel free to contact us!

Related products /news:

Mechanical seal and bearing, mechanical graphite products

Mechanical properties of graphite