A fabric is defined as an integrated fibrous structure produced by fiber entanglement of yarn interlacing, interloping, intertwining, or multiaxial placement. Fiber felts, composed of fabrics formed directly from fibers, are an example of fiber-to-fabric structures. This research concentrates on yarn-to-fabric structures.

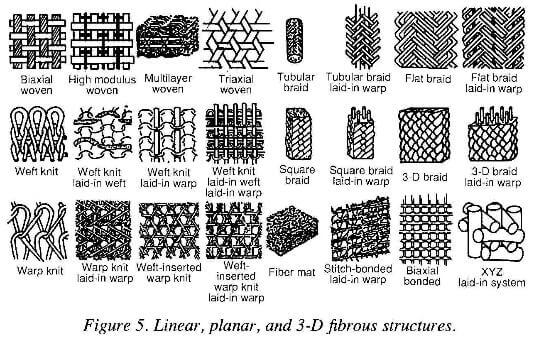

linear, planar, and 3D fibrous structures

While the weaving, braiding, and knitting techniques can produce planar or 3D structures, the nonwoven fabrics are mainly for 3D systems. Yarn orientation distribution and the number of yarn diameters in the thickness direction distinguish 2D and 3D fabrics. A 2D fabric consists of two or three yarn diameters in the thickness direction with fibers oriented in the x-y plane. A 3D fabric, consisting of three or more yarns in the thickness direction, is a fibrous network wherein yarns pass from surface to surface of the fabric in all three directions.

The key criteria for selecting the fiber architecture for structural composites are: the capability for in-plane multiaxial recinforcement, the through-the-thickness reinforcement, and the capability for formed-shape and/or net-shape manufacturing. Depending on the processing and end-use requirements, some or all of these features are required. In this section, the representative structural geometry of 2D and 3D fabrics is introduced.